-

From the Steel Detailing section of the action bar, click Member-Driven

Plate

. .

The building is hidden, the catalog members are shown as transparent,

and their neutral axes are displayed. Pickable segments of plates and of clip

angles are also displayed.

-

Select a positioning point on the neutral axis of a catalog member, a plate,

or a clip angle.

-

In the Member-Driven Plate dialog box, select the shape

of the plate.

- To create a rectangular

plate, perform the following steps:

- Click Rectangle

. .

- In the Length

U and Length V boxes, specify

the lengths of the rectangle in the U and V directions.

- In the

Rotation box, specify an angle to rotate

the rectangle about its center in the same positioning plane.

- In the Chamfer

length box, specify the chamfer length. Select the

check boxes corresponding to the plate's corners that you want to

chamfer.

- In the

Thickness box, specify the thickness of

the plate.

Note:

You can click  to swap the values of the Length U and the

Length V of the rectangular plate.

to swap the values of the Length U and the

Length V of the rectangular plate.

- To create a square plate,

perform the following steps:

- Click

Square

. .

- In the

Length box, specify the length of side of

the square.

- In the

Rotation box, specify an angle to rotate

the square about its center in the same positioning plane.

- In the Chamfer

length box, specify the chamfer length. Select the

check boxes corresponding to the plate's corners that you want to

chamfer.

- In the

Thickness box, specify the thickness of

the plate.

- To create a triangular

plate, perform the following steps:

- Select

Triangle

. .

- To rotate the triangle by 90 degrees about its normal, click

Snap Rotate About Normal

. .

- To flip the normal of the UV plane, click

Reverse

. .

- In the Length

U and Length V boxes, specify

the lengths of the triangle in U and V directions.

- In the

Rotation box, specify an angle to rotate

the triangle about its center in the same positioning plane.

- In the Chamfer

length box, specify the chamfer length. Select the

Chamfer -U,-V check box to chamfer the

right-angled corner of the triangle.

- In the

Thickness box, specify the thickness of

the plate.

Note:

You can click  to swap the values of the Length U and the

Length V of the triangular plate.

to swap the values of the Length U and the

Length V of the triangular plate.

- To create a round plate,

perform the following steps:

- Select

Round

. .

- In the

Diameter box, specify the diameter of the

plate.

- In the

Thickness box, specify the thickness of

the plate.

- To create a plate of any

other shape, perform the following steps:

- Select

Profile

. .

- Select a closed profile.

- To rotate the closed profile by 90 degrees about profile’s normal,

click Snap Rotate About Normal

. .

- To flip the normal of the UV plane, click

Reverse

. .

- In the

Rotation box, specify an angle to rotate

the profile about its center in the same positioning plane.

- In the

Thickness box, specify the thickness of

the plate.

Note:

When you position a member driven plate on a round

host member, a Revolve box appears. This parameter

specifies the angle by which the plate is revolved around the neutral axis

of the host member.

-

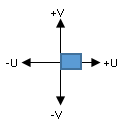

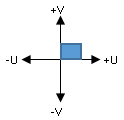

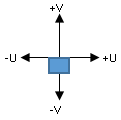

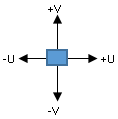

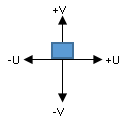

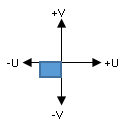

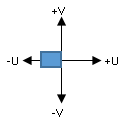

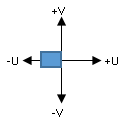

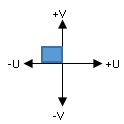

To position the origin of the U, V axes of the plate relative to the host

column, select any one alignment point.

Note:

The alignment points that can be selected are displayed in the

work area.

-

Click Snap Rotation To Next Plane

to change the orientation of the plate and link it to another plane relative to

the host member.

to change the orientation of the plate and link it to another plane relative to

the host member.

-

Align the plate in the U and V directions.

| Orientation |

V minus

|

V center

|

V plus

|

U plus

|

|

|

|

U center

|

|

|

|

U minus

|

|

|

|

-

Select the thickness orientation of the plate.

| Option | Description |

|---|

Front side

|

Applies the thickness on the positive side of the UV plane.

|

Back side

|

Applies the thickness on the negative side of the UV plane. |

Both sides

|

Applies the thickness centered on the UV plane. |

-

Click Member-Driven Plate Options

and specify the offsets for the plate in the U, V, and W directions. and specify the offsets for the plate in the U, V, and W directions.

Notes:

- You can click

to reset the offset values. to reset the offset values.

- You can select the Show additional

alignment points check box to display the additional

alignment points that can be selected.

-

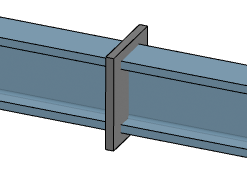

Click Ok

. .

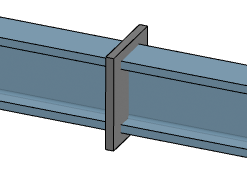

The member-driven plate is created.

|

.

The building is hidden, the catalog members are shown as transparent, and their neutral axes are displayed. Pickable segments of plates and of clip angles are also displayed.

.

The building is hidden, the catalog members are shown as transparent, and their neutral axes are displayed. Pickable segments of plates and of clip angles are also displayed. .

.  to swap the values of the Length U and the

Length V of the rectangular plate.

to swap the values of the Length U and the

Length V of the rectangular plate.  .

.  .

.  .

. .

. to swap the values of the Length U and the

Length V of the triangular plate.

to swap the values of the Length U and the

Length V of the triangular plate.  .

.  .

.  .

. .

. to change the orientation of the plate and link it to another plane relative to

the host member.

to change the orientation of the plate and link it to another plane relative to

the host member.

and specify the offsets for the plate in the U, V, and W directions.

Notes:

and specify the offsets for the plate in the U, V, and W directions.

Notes: to reset the offset values.

to reset the offset values.  .

The member-driven plate is created.

.

The member-driven plate is created.