Defining Composite Shell Sections | |||||

|

| ||||

-

From the

Finite Elements section of the action

bar, click Composite Shell Section

.

.

- Optional: Enter a descriptive Name.

-

Select a geometry support.

A composite shell section must be applied to one or more surface geometries with associated composite parameters. You can also use geometry from an ordered geometric set.

Note: The support for each composite shell section must include a consistent use of grid-, ply-, or zone-based (grid, virtual stacking grid, plies, ply groups, cores, sequences of plies) items to be consistent with the sections defined in the Composites Design app. -

To define the support for the Composites definition, do

one of the following:

- Select the support directly from the 3D area or the tree.

- Set the selection method to Grid

, and select one of the composite grids defined

using a grid or virtual stacking grid.

, and select one of the composite grids defined

using a grid or virtual stacking grid.

Tip: Use [Ctrl]+[Click] to select multiple values. - Optional:

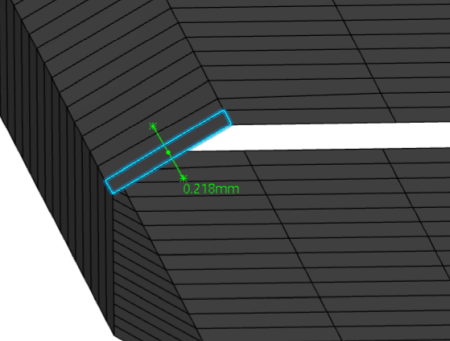

Adjust the core sampling depth, which is the distance tolerance the app uses

while searching for composite geometry to associate with the core sampling

points on the mesh. You can edit the value directly, or you can use the

interactive depth visualization tool:

-

Click Visualize core sampling depth.

The depth visualization tool appears on one of the elements in the support.

Tip: Click other elements to display the visualization tool at other locations. - Optional: Drag the ends of the depth indicator to change the core sampling depth interactively.

-

Press Escape to return to the

Composite Shell Section dialog box.

If you edit the depth value directly in the dialog box after you have displayed the core sampling depth, the depth visualization updates accordingly.

-

Click Visualize core sampling depth.

-

Select Include nonstructural ply thickness to create

dummy plies to account for the thickness of nonstructural plies.

-

From the Position options, select one of the

following options for the location of the dummy plies.

Option Description Top only Adds one dummy ply to the composite at the top of the layup. The thickness of this ply is equal to the total of the thicknesses of all nonstructural plies in the layup.

Bottom only Adds one dummy ply to the composite at the bottom of the layup. The thickness of this ply is equal to the total of the thicknesses of all nonstructural plies in the layup.

Top and Bottom Adds two dummy plies, one at the top and another at the bottom of the layup. The thickness of each dummy ply is equal to half the total of the thicknesses of all nonstructural plies in the layup.

- Assign a Material for the dummy plies. Because these are nonstructural plies, choose a material with properties that have negligible mechanical effects in the simulation.

- Specify the Ply angle to assign to the dummy plies.

-

From the Position options, select one of the

following options for the location of the dummy plies.

-

Do one of the following:

- If the response of the shell is linear elastic, select Integrate section before analysis to calculate the cross-sectional behavior by linear moment-bending and force-membrane strain relationships.

- If the shell material includes nonlinear behavior, clear Integrate section before analysis to calculate the cross-sectional behavior by numerical integration through the shell thickness.

-

From the Integration scheme options, select

Simpson's rule or Gauss

quadrature.

If you require results output on the composite shell surfaces, use integration based on Simpson's rule. Otherwise, use Gauss quadrature integration.

-

Enter a value for the number of Integration points to

be used through the composite shell section.

The default is three points if you use Simpson's rule and two points if you use Gauss quadrature.

-

Enter a value for the number of Field points to be used

through the composite shell section.

This value is used for the temperature or field points. By default it matches the number of integration points.

-

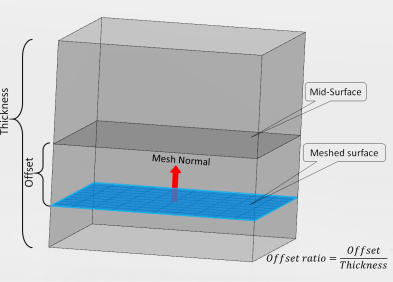

From the Offset definition options, choose one of the

following:

Option Description Automatic The app calculates the offset automatically by taking into account the defined ply thicknesses and stacking directions. None The geometry support for the composite shell and the center of the shell thickness are coincident. Specify distance Distance (measured along the positive normal direction of the shell) between the geometry support and the center of the composite shell thickness. Ratio of thickness Distance specified as a fraction of the shell thickness (and measured along the positive normal direction of the shell) between the geometry support and the center of the composite shell thickness. Top surface The geometry support for the composite shell represents the top surface of the shell. Bottom surface The geometry support for the composite shell represents the bottom surface of the shell. From solid Offset value is extracted from the solid geometry that you select, as shown in the image below.

- Click OK.