-

From the Review section of the action bar,

click Nesting

. .

-

Select the layer to nest.

-

Enter the Material Roll definition.

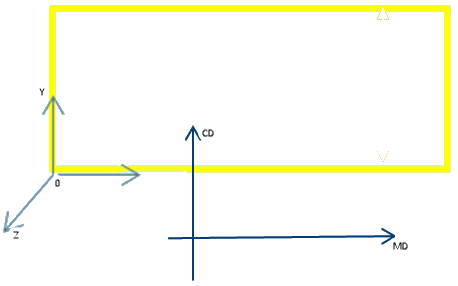

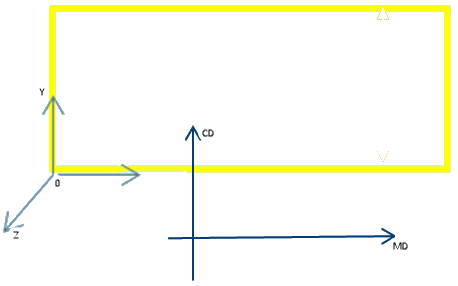

The material roll is considered as rectangular, with its left bottom angle on the

origin of the material axis system, The X-axis in the Machine Direction, the Y-axis in the

Cross Direction.

- MD Width: Roll dimension parallel to MD.

- CD Height: Roll dimension parallel to CD.

- Left and right margins: Minimum distance between the pieces

and the boundaries of the material roll, parallel to Y-axis.

- Bottom and top margins: Minimum distance between the pieces

and the boundaries of the material roll, parallel to X-axis.

-

Set the distance between pieces.

- Optional:

Select the Replicate group of pieces check box and enter the

number of pieces in the group.

A group of the given number of pieces is created, to be

replicated on the material roll to optimize the number of nested pieces.

-

Select a Laying option.

- Maximize nested pieces number: Nesting is computed using

the three options below. The option that lays the greatest number of pieces is

kept.

- Column along CD, Duplication along MD: Pieces are laid on a

column along CD. The column is duplicated along MD, without rotation.

- Column along CD, Duplication along MD, rotation: Pieces are

laid on a column along CD. The column is then duplicated along MD and rotated at 180

degrees.

- Row along MD, Duplication along CD, rotation: Pieces are

laid on a row along MD. Then alternate duplications of the row are made along the CD,

with a 180 degrees rotation.

-

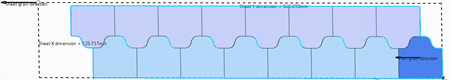

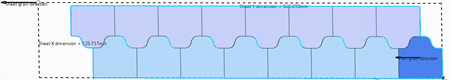

Press Preview.

The nesting is displayed in the 3D area. The

number of nested pieces and the used area are displayed in the dialog box.  -

Validate

A nesting feature is created under the tree. It contains an editable NestingPieces features and the nesting roll

boundaries.

|

.

.