About the Forming Process | ||

| ||

- One or more pieces of composites material are laid up on a flat surface.

Each piece is called a blank.

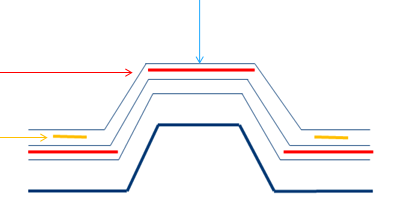

In the image below showing matched-die forming, the punch and die are shown is blue, the blank in red, the blank holder in orange.

- The stack of blanks is formed to a three-dimensional shape, using shaped tools.

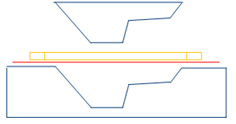

In the image below, showing the use of multiple punches and grippers acting in multiple phases, the punches are numbered and in blue, the form is shown in blue at the bottom, the blank in red, the grippers are the arrows.

- During forming, blanks are held in place by the blank holders, grippers or diaphragms, or a

combination of these.

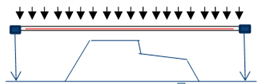

In the image below, showing diaphragm forming, the frame, and diaphragms are in black, the blank is in red and the form in blue.

- The edges of the formed blanks are usually trimmed because of material damage or movement.

The composites materials are either:

- Dry, having no resin.

A thermoplastic powder binder typically gives the formed preform adequate stiffness for handling and subsequent resin infiltration.

- Or wet, impregnated with thermoset or thermoplastic resin.

The resin is typically cured in the formed shape.

Co-forming multiple blanks/plies allows for quick manufacture of complex layups. A typical forming stack can consist of many different plies:

- Overall Plies (blue arrow)

- Maintain integrity during forming.

- Typically biaxial material to ensure good forming.

- 1-4 plies fabric (for example +/-45, 0/90, +/- 45).

- Structural Reinforcement (red arrow)

- For example, top and bottom of rib stiffener.

- Aligned with load paths.

- Typically UD yarns with transverse fibers to improve handling.

- Local Reinforcement (yellow arrow)

- For example, at fixing locations.

- Relatively small.

- Often random fibers.