-

From the Tooling Geometry section in the action bar,

click Generative Form Block

.

.

-

Select the inputs for the block:

-

Select the Shape (surface to process).

If you had left Block Name blank, a default name is

proposed. You can edit it.

-

Select the Axis System.

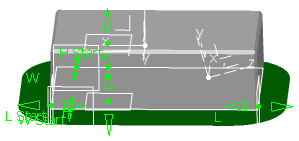

A profile is proposed, built from the maximum extremums: It is resizable:

- Optional:

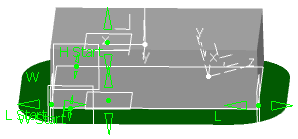

Click Switch to use a profile based on the minimum extremums:

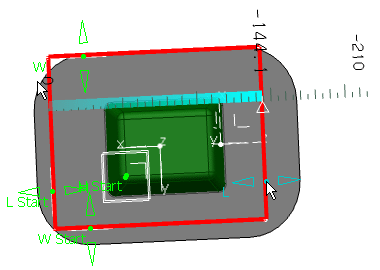

- Click Apply.

A block is computed:

-

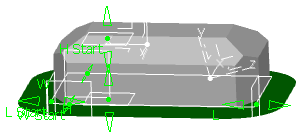

Regarding the Pad:

-

Clear the Chamfer check box if a chamfer is not

required.

-

If a chamfer is required, edit its Length and its

Angle.

-

Clear the Create Pocket check box if you do not want to create a

pocket.

- If you create a pocket:

- Clear the Edge Fillet check box if you do not want to fillet the pocket.

- Otherwise, enter the radius of the edge fillet.

-

Regarding the draft:

- Clear the draft angle check box if you do not want to draft the pad and the pocket.

- Edit the angle of the draft if you want to create one.

The pad and the pocket are created with a 1-degree draft.

- Optional: Click More.

-

Edit the Block Position.

-

Edit the Block Size.

The pad and the pocket (if required) are created with the corresponding parameters and relations.