Creating an Insert Manager | ||

| ||

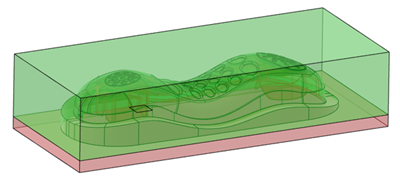

Two types of features are created under the Inserts node:

- InsertManager that is a manager with its own update, dedicated

to create and update core and cavity inserts, depending on the inputs (Pulling

direction, core and cavity side surfaces, and possibly a parting plane).Note: Parameters are stored under InsertManager

- CavityBlockSize

- CoreBlockSize

- TopOffset

- BottomOffset

- PartingPlaneOffset

- InterlockSurfaceDraftAngle

- Insert features: InsertCavity and InsertCore. Both are typed volumes.

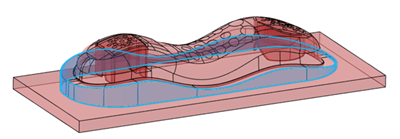

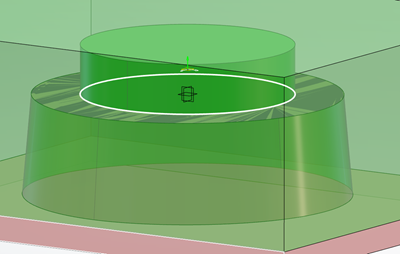

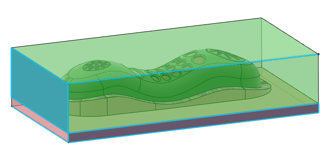

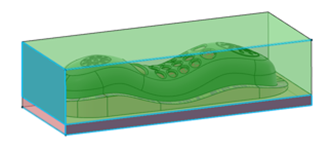

Below are some examples:

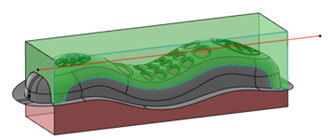

- Interlock surface, no draft.

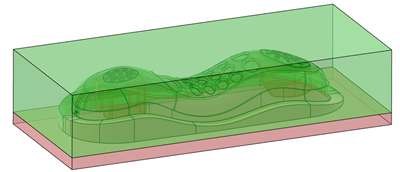

- Interlock Surface with default draft. The edge at the top of the draft is inside the

parting surface.

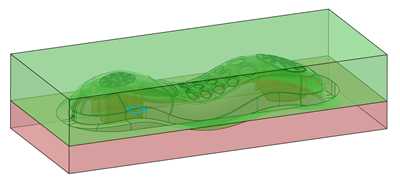

- Interlock surface with reversed draft. The edge at the top of the draft is the same as

the edge of the parting surface.

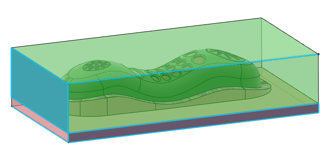

Note:

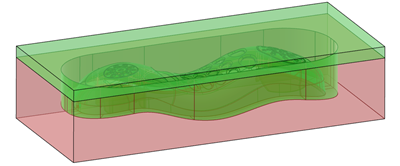

Topology can change between two constructions modes. For example, If the sketch profile

is outside the side surfaces

- When the sketch is modified but stays outside, the building strategy remains the same,

the topology follows.

- When the sketch is modified and goes inside the surface, the building strategy

changes, the topology does not always follow.