-

From the section of the action bar, click Connect Checker Analysis

. .

- In the Type area, select the type of connection you want to check.

- Curve-Curve Connection

- Surface-Surface Connection

- Surface-Curve Connection

In this example, Surface-Surface Connection

is

selected because we are analyzing only the connection between two

surfaces. - Select one or several elements.

- Select Quick display mode.

The quick analysis provides a simple visual indication of connections

which exceed the threshold values for each selected continuity analysis

type. -

Select the continuity analysis type to display.

- Overlap Defect: overlapping elements (selecting

this disables the other analysis types)

- G0 continuity: continuity in

point

- G1 continuity: continuity in

tangency

- G2 continuity: continuity in

curvature

- G3 continuity: continuity in

curvature tangency

Note:

Depending upon your selection in the

Type area, you may be able to select more than

one analysis type.

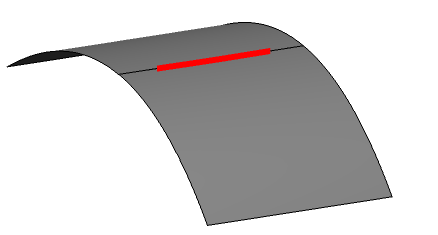

In this example, G0

continuity is selected. The visual representation of the

analysis appears on the elements. In the example, the thick red line

indicates all points that are separated by a gap which exceeds the threshold

value for G0 continuity, which in this example is set

at 0.1 mm.  The Max Deviation area at the bottom displays the

maximum values of the G0, G1, G2 and G3 continuities. - Optional: Use the spin boxes to adjust the threshold values.

The visual representation of the analysis is updated. -

Optional: If you are analyzing elements which have been joined

(using a join or match command) and you want to analyze the internal

connections, select Internal Edge

(this

command is by default unselected). (this

command is by default unselected).

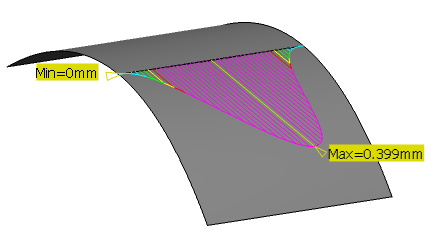

- Clear Quick display mode to display the full mode's options, and then select Comb

and Envelope and Envelope  . .

The thick red line of the quick analysis is replaced by a comb of spikes

bounded by an envelope.

The color of a spike indicates whether the connection at the position of the

spike is below the threshold value and the length of the spike indicates the

magnitude of the discontinuity.

- In the Information area, select MinInfo

and MaxInfo and MaxInfo  . . The minimum and maximum values of the analysis are displayed on the

element.

- Adjust the analysis color scale on the element:

- In the Display area, select Full Color Scale

. .The color scale dialog box is displayed. - In the color scale dialog box, select the

Auto Min Max check box.

- The maximum and minimum values in the dialog box are set according to

the values detected on the element.

- The analysis colors are updated to match the color scale in the dialog

box.

Note:

To access the Edit and the

Unfreeze contextual commands for a color and a

value on the color scale, ensure that the Auto Min

Max check box is cleared.

-

Click

OK. The analysis

is added to the

tree

and will be updated automatically whenever you modify any of the input

elements.

|