Creating Core Samples | ||

| ||

-

From the Review section of the action bar, click Multiple Core Samples

.

.

-

Manage core sample groups from the top of the dialog box.

Group List displays all the core sample groups present in the model.

-

Select a core sample group in the list.

Tips: - When you start Multiple Core Samples, a core sample group feature is created as the current group in the list.

- When you edit an existing core sample group, that group is the current group in the list.

The dialog box is populated with the information of the core samples of that group. -

Alternatively, click New in the list to create a new core

sample group.

- The core samples are created as CS.x under a Core Sample Group under Review tools. Both are editable.

- A standard name is proposed, such as Core Sample Group.x

- A label with a leader line is attached to the core sample.

- The label is always parallel to the screen.

- Whatever the zoom factor, the size of the label remains the same.

- Drag the label to position it.Note: The dragged position is not kept.

- Change the color of the label and of the leader from the graphic

properties.Note: You cannot edit the size or the font of the core samples texts.

- Hide or show individual core sample groups.

-

To customize the name of the core sample groups, key in a Group

Prefix and a Group Starting Index. Click

Rename Group.

- The name of the Reference Entity (if any), is proposed as Group Prefix.

- If the group was created from several reference entities, the name of the last reference entity used is proposed.

- The core sample group is renamed from the value of Group Prefix.

- The core samples in the group are renamed from the group name and the index.

- The tree is updated accordingly.

-

Select a core sample group in the list.

-

Select the Display all Core Samples check box to display the

core samples instead of the groups.

- All the core samples from all groups are listed in the table.

- Export exports all the core samples from all groups in one file.

- New core samples are created in the current core sample group.

- Use the context menu to move one core sample from one group to another.

-

Select a surface or a plies group to define the Support Surface for Core

Sample.

- Selecting a plies group reverts to selecting its associated surface. All the plies of the plies group found along the normal to its surface are processed.

- If the selected surface is not that associated to the plies group, points selected

on this surface are processed as follows:

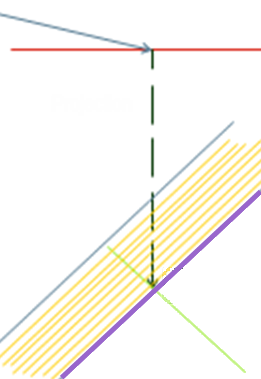

- The first plies group found is represented by the yellow lines (plies) and the purple line (its reference surface).

- The selected surface is shown in red.

- The blue arrow points to the selected point.

- The dotted green arrow shows its projection on the reference surface of the first plies group found.

- The green line is the normal to the reference surface of the plies group at the projection of the selected point.

- Multiple Core Samples processes all the plies of that plies group found along this line.

-

Optional: Select the No direct computation check

box.

The core samples and the results are computed/updated only after you click Apply.

-

Pick points directly in the 3D area to create the core samples.

The core samples are added to the list.

-

Alternatively, click Create Points from Reference Entity.

-

Select a reference entity

It can be:

- A grid or a virtual stacking: A point is created at the center of each cell of the grid.

- A zones group: A point is created at the center of each zone.Note: If the zone contains a transition zone, the point is created on the portion with no transition zone, meaning it is not at the exact center.

- A plies group: A point is created in each surface with a constant thickness area.

- An Iso-Thickness Areas group. The ITA points from the group are used as locations of the core samples. This way, you can mark zones with the same thickness if an ITA group already exists.

- If you have selected a plies group, define the width of the areas to consider. Either key in a value, or measure the distance between two plies.

- Click OK.

- The core samples are created and listed under List of Core Samples with their details.

- Associativity between the core samples and the reference entity is managed by manual editing.

- If you have selected a grid, virtual stacking or a zone group, they are listed under Reference Entity.

-

Select a reference entity

-

Back in the main dialog box, click Apply.

- Index is the order of the core samples.

- Name is the name of the core sample. Click a name to edit it.

- Surface Reference

- Ply is the name of the ply found under the point. It is not editable.

- Thickness is the value of the laminate found under the point. It is not

editable.The computation of thickness may be inaccurate when the computed equivalent

shell of a core is not the same as the cross section of a core that touches or is

nearest to the support surface.

- Point is the name of the point you have picked. It is not editable.

- Hide/Show indicates the visibility status. Click either Hide or Show to modify this status.

- Direction can be Normal (to the surface) or Invert. Click Invert direction in the dialog box, or the arrow in the work area to modify it.

- Cut-Pieces, Non Struct Plies and Filters are the options selected for the core samples as you picked the point.

- Reference Entity

- Difference

Results is enabled only when you select one core sample.

- Select one or several core samples in the List of Core Samples.

- Click Invert Direction, Hide, Show, Remove to modify the direction, the visibility status or delete the core samples.

-

Check the Results

- List of Plies lists the details of the plies.

- Number of entities

- Total thickness

- Plies groups

- Sequence

- Entity

- Material

- ThicknessNotes:

- For plies and cut-pieces, the corresponding material thickness is shown.

- For cores, the length of intersection between the solid of core and the core sample line is shown.

- Direction Name

- Direction Value

- Rosette

- Thickness Law lists the details of the thickness law of the core sample:

- Material

- Thickness law as a number of plies and percentage for each direction

- Total number of ply for each direction if there is more than one material

- Delta Comparison lists the delta found when comparing the core sample

and the entity thickness law.

- Name of the entity.

- Material

- Delta

- Details of the directions

- Status of the delta

- Status of the thickness

- Total delta difference

- Thickness difference between the core sample and the reference entity

- List of Plies lists the details of the plies.

- Optional:

Click More (for export).

- Click ... to enter the name of the exported file.

-

Select the Export Format.

See also .

-

Select the information to export. Decide if you want to export the

Names, or the Names + Values of the

Orientations.

- For all three export formats, you can export the orientation Names or Names + Values.

- For Core Sample only, you can export the Entity thickness.

- Optional: Select the Open file after creation check box.

- Click Export to create the exported file.

Examples of:- Ply Table:

Reference Geometry Ply Group Sequence Ply/Insert Material CS.1 CS.2 Extrude.1 PG.1 Sequence.1 Ply.1 KEVLAR4 90 Extrude.1 PG.1 Sequence.2 Ply.2 KEVLAR4 -45 Extrude.1 PG.1 Sequence.3 Ply.3 KEVLAR4 0 Extrude.1 PG.1 Sequence.4 Ply.4 KEVLAR4 45 Extrude.1 PG.1 Sequence.5 Ply.5 KEVLAR4 90 Extrude.1 PG.1 Sequence.6 Ply.6 KEVLAR4 0 Extrude.1 PG.1 Sequence.7 Ply.7 KEVLAR4 -45 Extrude.1 PG.1 Sequence.8 Ply.8 KEVLAR4 45 Extrude.1 PG.1 Sequence.9 Ply.9 KEVLAR4 90 90 Extrude.1 PG.1 Sequence.10 Ply.10 KEVLAR4 -45 -45 Extrude.1 PG.1 Sequence.11 Ply.11 KEVLAR4 45 45 Extrude.1 PG.1 Sequence.12 Ply.12 KEVLAR4 0 0 DIR 0 1 3 DIR 45 1 3 DIR -45 1 3 DIR 90 1 3 Total Crossed Entities 4 12 Thickness 0.8mm 2.4mm Core Sample Points X Y Z CS.1 139.578205mm -10mm 14.228437mm CS.2 -92.186211mm -10mm 17.124897mmAll plies are listed by their name. The plies with multiple intersections, if any, are listed at the end, the number of multiple intersections is given for each ply concerned. - Core Sample:

Core Sample CS.1 139.578205mm -10mm 14.228437mm Ply Group Sequence Ply/Insert Material Direction Rosette PG.1 Sequence.12 Ply.12 KEVLAR4 0 Rosette_SP PG.1 Sequence.11 Ply.11 KEVLAR4 45 Rosette_SP PG.1 Sequence.10 Ply.10 KEVLAR4 -45 Rosette_SP PG.1 Sequence.9 Ply.9 KEVLAR4 90 Rosette_SP DIR 0 1 DIR 45 1 DIR -45 1 DIR 90 1 Total Crossed Entities 4 Thickness 0.8mm Core Sample CS.2 -92.186211mm -10mm 17.124897mm Ply Group Sequence Ply/Insert Material Direction Rosette PG.1 Sequence.12 Ply.12 KEVLAR4 0 Rosette_SP PG.1 Sequence.11 Ply.11 KEVLAR4 45 Rosette_SP PG.1 Sequence.10 Ply.10 KEVLAR4 -45 Rosette_SP PG.1 Sequence.9 Ply.9 KEVLAR4 90 Rosette_SP PG.1 Sequence.8 Ply.8 KEVLAR4 45 Rosette_SP PG.1 Sequence.7 Ply.7 KEVLAR4 -45 Rosette_SP PG.1 Sequence.6 Ply.6 KEVLAR4 0 Rosette_SP PG.1 Sequence.5 Ply.5 KEVLAR4 90 Rosette_SP PG.1 Sequence.4 Ply.4 KEVLAR4 45 Rosette_SP PG.1 Sequence.3 Ply.3 KEVLAR4 -45 Rosette_SP PG.1 Sequence.2 Ply.2 KEVLAR4 -45 Rosette_SP PG.1 Sequence.1 Ply.1 KEVLAR4 90 Rosette_SP DIR 0 3 DIR 45 3 DIR -45 3 DIR 90 3 Total Crossed Entities 12 Thickness 2.4mmThe plies are listed in the order they have been processed, which makes the multiple intersections more visible, if any. - Ply Table For Import

(CPG stands for CutPieceGroup and CP for CutPiece)

PlyGroup Sequence Ply CPG CP Material Direction Rosette Surface Draping Ply ID CS.1 CS.2 PG.1 Sequence.1 Ply.1 KEVLAR4 90 Rosette_SP Extrude.1 F 1 90 PG.1 Sequence.2 Ply.2 KEVLAR4 -45 Rosette_SP Extrude.1 F 2 -45 PG.1 Sequence.3 Ply.3 KEVLAR4 0 Rosette_SP Extrude.1 F 3 0 PG.1 Sequence.4 Ply.4 KEVLAR4 45 Rosette_SP Extrude.1 F 4 45 PG.1 Sequence.5 Ply.5 KEVLAR4 90 Rosette_SP Extrude.1 F 5 90 PG.1 Sequence.6 Ply.6 KEVLAR4 0 Rosette_SP Extrude.1 F 6 0 PG.1 Sequence.7 Ply.7 KEVLAR4 -45 Rosette_SP Extrude.1 F 7 -45 PG.1 Sequence.8 Ply.8 KEVLAR4 45 Rosette_SP Extrude.1 F 8 45 PG.1 Sequence.9 Ply.9 KEVLAR4 90 Rosette_SP Extrude.1 F 9 90 90 PG.1 Sequence.10 Ply.10 KEVLAR4 -45 Rosette_SP Extrude.1 F 10 -45 -45 PG.1 Sequence.11 Ply.11 KEVLAR4 45 Rosette_SP Extrude.1 F 11 45 45 PG.1 Sequence.12 Ply.12 KEVLAR4 0 Rosette_SP Extrude.1 F 12 0 0 DIR 0 1 3 DIR 45 1 3 DIR -45 1 3 DIR 90 1 3 Total Crossed Entities 4 12 Thickness 0.8mm 2.4mm Core Sample Points X Y Z CS.1 139.578205mm -10mm 14.228437mm CS.2 -92.186211mm -10mm 17.124897mm