How It Works

Plies From Slicing is done in several steps.

- Computes the contours of the plies (inner and outer) from the curves of each Geometrical Level node of the Slicing Curves Group feature.

- Scans the thickness laws of each zone to define the material/orientations to be assigned to the plies.

- Generates sequences and plies (contour + material/orientation) that

are compatible with the zones thickness laws:

- A new sequence is created for each Geometrical Level.

- Inside each sequence, a new ply is built for each contour found in the Geometrical Level.

- A knowledge parameter containing the Geometrical Level information is stored for each sequence and ply created.

- If incorrect slicing curves are found in a geometrical level (for example a curve of an inner contour intersects the outer contour or the contour itself), making the computation of the contour impossible, the computation of the plies fails for the corresponding sequence only.

- The ExtrapolDist parameter is taken into account. When a gap greater than ExtrapolDist is found in slicing curves, the corresponding plies have open contours. They are listed in a message.

- Plies with an invalid contour are highlighted by the ply table command.

- Assigns a rosette to the generated plies:

- If you have selected an existing plies group, the plies inherit the rosette of this plies group.

- If you create a new plies group and if the Slicing from Solid was made with the Thickness Law option, the plies inherit the rosette of the zones found in the zones group.

- If you create a new plies group and if the Slicing from Solid was made with the Constant Thickness option, you need to select a rosette.

Notes:

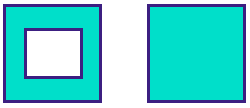

- Window plies (that is, plies with inner contours) are allowed. For example, in a given

geometrical level, the following configuration generates 2 plies in the same sequence.

The first ply has 2 contours (one inner, one outer) and the second ply has one

contour.

- For "on surface" contours, a smoothing operation reduces the number of micro-edges.