About Stagger Origin Points | ||

| ||

-

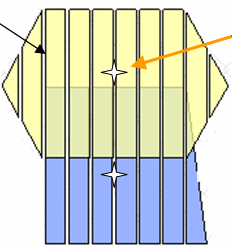

Top view of plies without staggering:

- The black arrow points to the tape.

- The orange arrow points to the origin point.

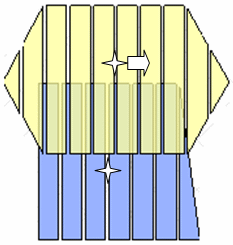

- Top view of the same plies with staggering:

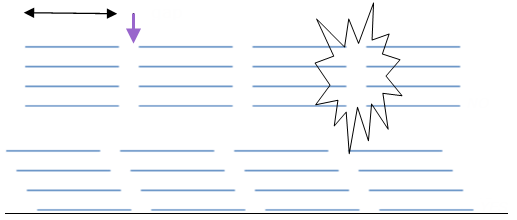

- Front view of the same plies, first without staggering, then

with staggering:

- The tape/tow is shown by the double-headed arrow.

- The gap is shown by the purple arrow.

- The top plies are shown without staggering (see inside the shape), whereas the bottom plies are shown with staggering.

Define Stagger Origin Points generates stagger origin points for each ply and verifies the validity of existing ones.

The Origin point is the starting point used to tool a ply. Stagger origin points avoid the overlapping of tapes or tows junction.

The Reference point is the point used to generate stagger origin points, generally the origin of the rosette.

The output is:

- The origin point for each ply

- The analysis results and reason of failures, if any

- The preview in the dedicated viewer

- An exported table containing the stagger indexes and warning messages.