-

From the Producibility and Splicing section of the action bar, click Splice Plies from Producibility

.

.

-

Select the plies to create the cut-pieces.

Multiselection is available.

-

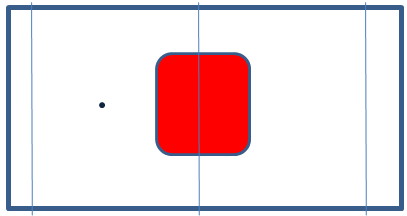

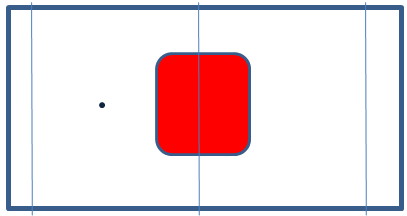

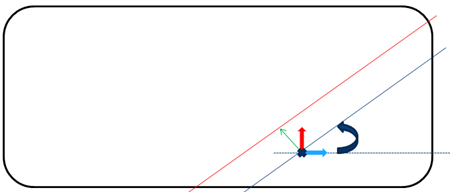

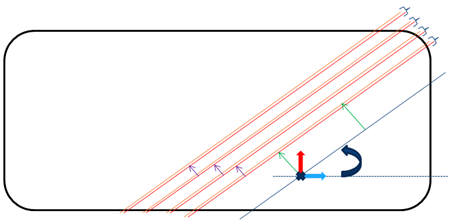

Enter the Fiber Mesh Parameters.

- Point: Start point (cross). Fiber mesh curves are created on the plane tangent to the ply

reference surface at the start point.

- Distance: Offset value applied to the rotated curve to build the result curve

(green arrow).

- Angle between the Warp vector and the result curve (circular arrow).

-

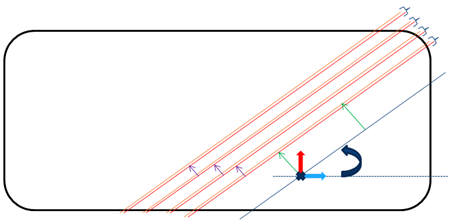

Enter the Splice Parameters to create the parallel curves (in red below).

- Staggering: Distance between the curve on a given ply and the curve on the next ply (purple arrows).

- Overlap between to consecutive cut-pieces.

- Repeat: Defines on how many plies the staggering is applied from the

start position (in the example below, 4).

- Offset: Distance by which the start position is translated to avoid cut superposition.

-

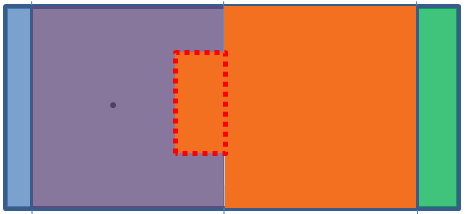

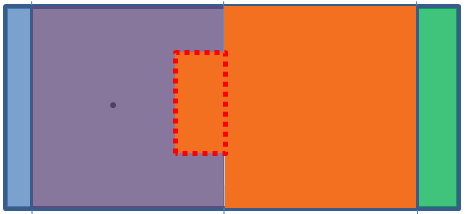

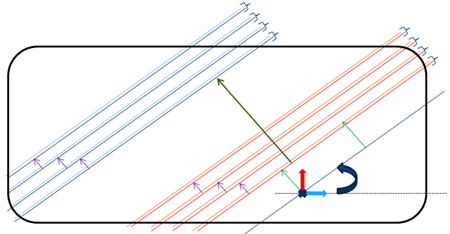

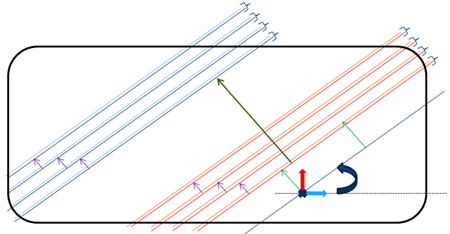

Select Repeat using Material Roll Width to create all the cut-pieces in one shot.

Below, the roll width is shown by the dark green arrow.

-

In the 3D area, click the blue arrow to orient the ply drop and the red arrow to orient the overlap.

The orientations are the same for all splicing curves.

A 3D Multisplice Group is created.

It contains a MultiSplice From Producibility node with:

- Provided parameter values (staggering, overlap, repeat status and associated offset).

- A Group of FiberMeshCurves.

Note:

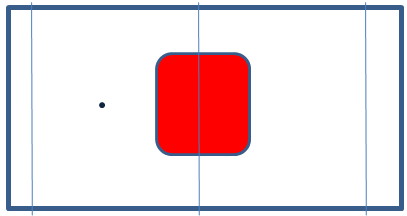

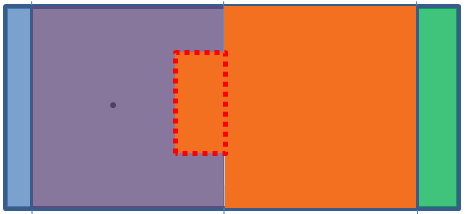

The generated cut-pieces do not support No Splice Zones nor Butt Splice Zones: The result could be larger than the roll width. In the example below, the No Splice Zone is the red square.

With the current start point, the cut-piece shown in orange is larger than the roll width.

By-pass: Move the input point to create curves outside the No Splice Zone.