Sectioning Items | ||

| ||

-

From the Markup section of the action bar,

click Section

.

.

You can also select the geometry before launching the command. The selected geometry is used to define the section plane. Based on the type of geometry, more geometry selections might be required.

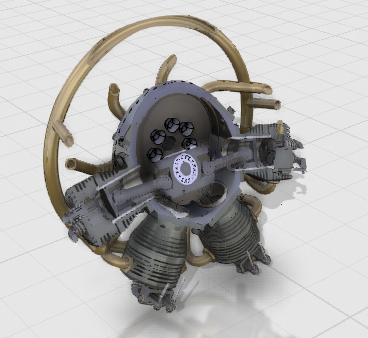

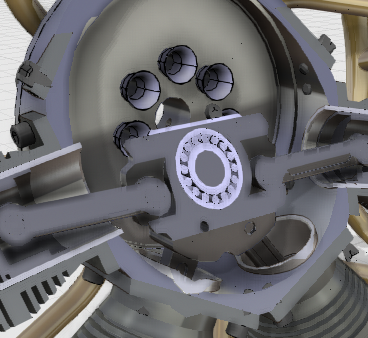

A section plane appears, cutting through the object.A context toolbar also appears.

-

Optional: To customize your section, choose from the following options in

the context toolbar:

Option Description  Flip

Flip

Reverses the cut side.  XYZ

XYZ

Displays options to orient the plane.  Position to X

Position to X

Orients the plane normal to the X axis.  Position to Y

Position to Y

Orients the plane normal to the Y axis.  Position to Z

Position to Z

Orients the plane normal to the Z axis.  Position from geometry

Position from geometryPositions the plane based on the selected geometries. The planed is positioned such that its normal (W-axis) is aligned to the normal of the plane defined by selected geometries that is closest to the opposite viewing direction and section plane is resized to fit inside the bounding box of the root product. When this option is selected, the selection filters are not available. If a geometry is selected as the first selection, the Ok option in the message box at the top of the 3D area is enabled. If the first selection is a planer surface, the section plane is automatically repositioned. If required, you can still select another valid second and third geometry for defining the plane. For more information, see Geometry Selection for Plane Positioning..

Tip: When you hover over a geometry, a temporary representation of the expected plane position and orientation is displayed.  Move Viewpoint

Move Viewpoint

Changes the viewpoint to display the section parallel to the screen.  Secondary Viewer

Secondary ViewerDisplays section curves in a dedicated 2D viewer. Use the options available on the left side of the viewer to:

- Print the content of the viewer.

- Reframe the content of the viewer.

- Rotate the content of the viewer by 90° clockwise.

- Rotate the content of the viewer by 90° counterclockwise.

- Flip the content vertically.

- Flip the content horizontally.

- Switch the background color to gray.

Color/Transparency Chooser

Color/Transparency ChooserModifies the background color and the transparency of the section.

To change the color, drag the slider or click in the bar. Click the icon to the left of the slider to switch between grayscale theme and colored theme. The icon to the right indicates the current color.

To change the transparency, drag transparency slider or click in the bar. Drag or click to the left to increase the transparency, and to the right to increase the opacity.

Remove

Remove

Removes the section and exits the Section  command.Note: Depending on their position, some markup objects (such as measurements or annotations) can be hidden to improve the display of cut objects.

command.Note: Depending on their position, some markup objects (such as measurements or annotations) can be hidden to improve the display of cut objects. -

To position your section plane, choose from the options available in the filter bar.

Filters let you position the section by snapping the Robot on the respective geometry type.

Option Description Point

The Robot is snapped on a point and the axes of the Robot are mapped to the reference axes of the root product. Center

The Robot is snapped on a center of a circle and the axes of the Robot are mapped to the reference axes of the root product. Axis System

The Robot is snapped on an axis system. Line

The Robot is snapped on a line. The origin is the point on the line where it is snapped and the w-axis lies on the line. Plane

The Robot is snapped on a planar surface. The origin is the point where it is snapped and the w-axis is normal to the planar surface. Cylinder/Cone

The Robot is snapped on a cylindrical or conical surface. The origin is the intersection point between the axis of the cylinder or cone and the line normal to this axis, passing through the point where the Robot is snapped. Surface

The Robot is snapped on any surface. The origin is the point where it is snapped and the w-axis is the line normal to the surface. Product

The Robot is snapped on the plane formed by the two of the main axes, closest to the viewer plane. The Robot is positioned at the center of the product bounding box. Note: For all the filters except the surface and product filter, the high quality representation of the selected geometry is loaded in the session.For line, surface, cylinder, cone, plane, and product, a temporary representation is displayed while snapping the Robot. -

Change the position of the section plane using one of the following methods:

Areas that can be manipulated are highlighted when you hover your mouse over them.

- To rotate the plane, drag its edges.

- To resize the plane, drag its corners.

- To position the plane on a specific surface of the object, use the Robot and the ruler, to position it precisely.Notes:

- You can manually position the origin of the ruler.

- You can enter the required value on the ruler for exact positioning of the section plane.

- In 3DPlay Web App, the ruler is displayed with less opacity.

- To translate the section plane, you can:

- Drag its surface

- Drag the Robot handles and enter the required value on the rule.

- Drag the slider to translate the

section plane by the specified increment value.

Note: To specify the increment value, click View Menu

Note: To specify the increment value, click View Menu and

enter the required value in the Increment box. The

increment value should be between the minimum and maximum increment values that

are computed as below:

and

enter the required value in the Increment box. The

increment value should be between the minimum and maximum increment values that

are computed as below:- Maximum increment value: closest & lowest decimal value to the distance between near and far planes divided by 10)

- Minimum increment value: closest & lowest decimal value to the

distance between near and far planes divided by 100)

The near plane is the plane parallel to section plane and tangent to the assembly bounding sphere which is the nearest to the viewing position.

The far plane is the plane parallel to the section plane and tangent to the assembly bounding sphere which is the farthest to the viewing position.

For example:- If the distance between near and far plane is 333 mm, the maximum increment value is 10 mm (333/10 = 33.3 ~ lowest decimal value is 10). While the minimum increment value is 1 mm (333/100 = 3.33 ~ lowest decimal value is 1).

- If the distance between near and far plane is 7500 mm, the maximum increment value is 100 mm (7500/10 = 750 ~ lowest decimal value is 100). While the minimum increment value is 10 mm (7500/100 = 75 ~ lowest decimal value is 10).

You can also select the Detailed View option to replace the slider with the value box for precise positioning of the section plane. You can enter the precise position within a specific range, otherwise, the closest limit value is taken into account.

The range is the distance between near and far plane.

Notes: When the w-axis of the section plane is aligned with one of the axes of the global axis system, the origin is the as same of the global axis system. If after manipulation, the w-axis of the section plane is not aligned with one of the axes of the global axis system, the origin is same as that of the origin of the Robot. In this case, the origin is reset every time you start the edition of section plane.

After the re-positioning is complete, the section curves are displayed (if the Compute contours preference is enabled.), thus making the contour of the cut geometry more visible and more accessible to create measures.See The Specific Case of Measurements Based on Section Curves.

- Optional:

To see the cut elements more clearly and access them more easily while creating the

section, click Hide Section Plane

.

The section plane is hidden. You can now measure items that were previously not accessible because to the section plane.

.

The section plane is hidden. You can now measure items that were previously not accessible because to the section plane.For more information, see Measuring Items.

To display the section plane again, click Hide Section Plane

.Notes:

.Notes:- As long as Hide Section Plane

remains selected, you can no longer view the section plane,

but you can still manipulate it by selecting the section contour. Of course, you can

also rotate or zoom the object, change your perspective, etc.

remains selected, you can no longer view the section plane,

but you can still manipulate it by selecting the section contour. Of course, you can

also rotate or zoom the object, change your perspective, etc.

- After you have creating the section, it is automatically hidden and

Hide Section Plane

is selected. To display the section plane, click to deselect

Hide Section Plane.

is selected. To display the section plane, click to deselect

Hide Section Plane.

- As long as Hide Section Plane

- Optional:

To see the contours on the section plane, do one of the following:

- From the Tools section of the action bar,

click Preferences

and select the Compute contour check

box.

and select the Compute contour check

box.Important: This option is only useful while creating a new section. For the already created sections, use the contextual command, explained below. - Right-click the section plane, select Properties

, and then in the Section tab, select

the Compute contour check box.Notes:

, and then in the Section tab, select

the Compute contour check box.Notes:- You can choose to compute contours for one or more sections, using this contextual command.

- The contours are displayed only if the loading is already complete.

- From the Tools section of the action bar,

click Preferences