Robot Controller Sampling Rate

The sample rate is a feature of each controller regardless of the type of device controlled: e.g., a PLC or a robot.

Sampling Rate or Heartbeat

This represents a rate at which the

interpolation calculations are made.

The sample

rate is a rate at which the controller samples its own internal state.

Some controllers are faster, which means they have a higher sample rate (in

Hertz). Though the sample rate

values vary, the typical range is from 12-50ms. It means that every 12-50ms, a controller performs one full cycle of internal state sampling. Internal

state can be the state of I/O, motion planning calculations, interrupt

sampling, etc. In terms of motion planning, the existence of a sample rate means that the

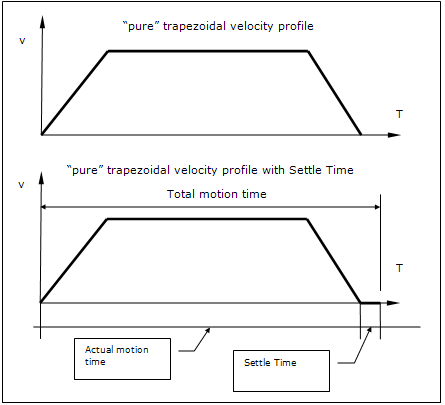

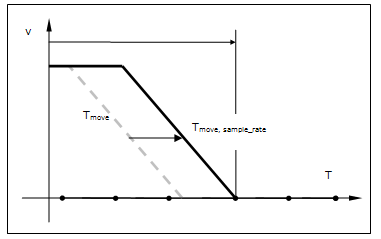

total motion time has to be a multiple of the sample rate. The figure below

illustrates a standard, trapezoidal velocity profile.

In the image above, the total amount of travel time

is represented by Tmove. The trapezoidal profile ends up

in between the dots representing the sample rate. This occurs due to the motion calculations. However, once the controller sample

rate criterion is applied, the motion time has to be extended to the first

multiple of the sample rate that is larger than Tmove, as the figure below illustrates.

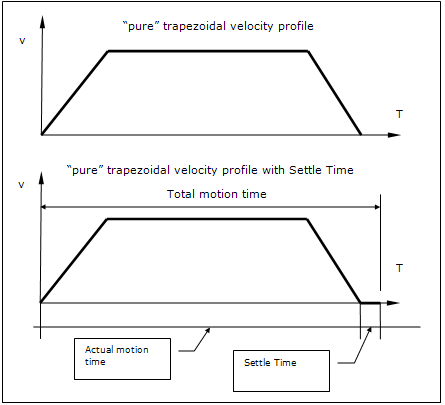

Settle time represents the amount of time between the moment the

motion stops and the moment vibrations of the mechanisms become

negligible.

The overall result is increase of the cycle time.

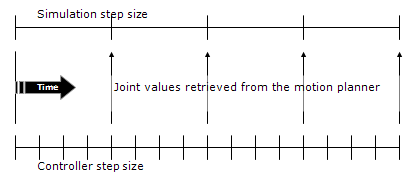

Sample Rate vs. Simulation Time

The key difference between the sample rate and

simulation time is that the sample rate represents time steps at which

motion interpolation takes place, while simulation time represents the

rate at which update of visualization takes place

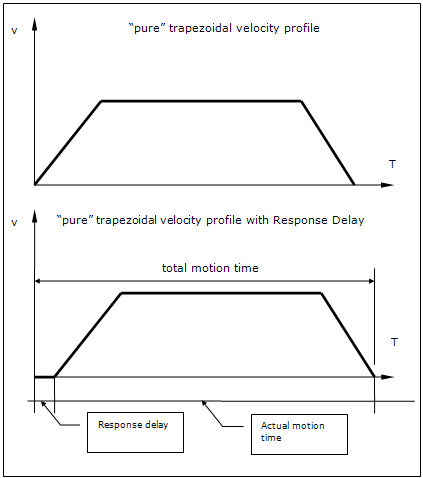

There are three possible cases when it comes to the

sample rate vs. simulation time: Response delay represents an amount of time between the moment the

motion command is issued by the controller and the actual start of

motion.

Settle time represents the amount of time between the moment the

motion stops and the moment vibrations of the mechanisms become

negligible.

The overall result is increase of the cycle time.