Using a Weld Template Primitive File | |||||

|

| ||||

-

From the Arc section of the action bar, click Weld Template System

.

You are prompted to select a robot.

.

You are prompted to select a robot. -

Select a robot.

The WTS Primitive File Open dialog box appears, and prompts you to select and open a valid primitive file.

-

Select a file and click Open.

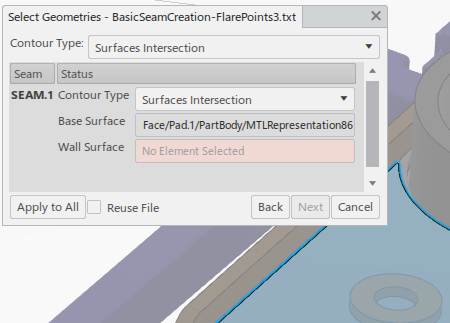

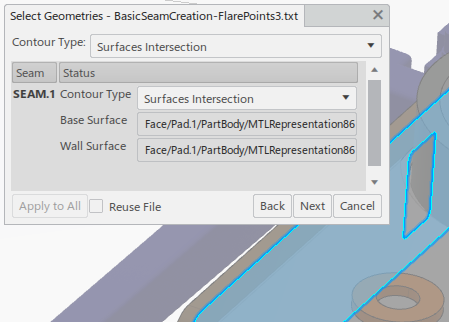

After the selected file is successfully parsed, the Select Geometries panel appears and prompts you to select one or more base surfaces, curves or tag groups.

- Select the Contour Type that will act as the default contour type for any contours whose type are unset.

-

Click in the Base Surface box and select all surfaces that will

serve as base surfaces in the work area.

When there is more than one selection, Base Surface maintains a count of the number of surfaces selected.

- Optional: Upon selecting geometry for a seam, you can click Apply to All to automatically apply that geometry selection to all seams.

-

Click in the Wall Surface box and select one or more wall

surfaces in the work area.

When there is more than one selection, Wall Surface maintains a count of the number of surfaces selected.

- Optional: Select Reuse File to automatically use the current primitive file the next time Weld Template System is launched.

-

When all surfaces are selected, click Next.

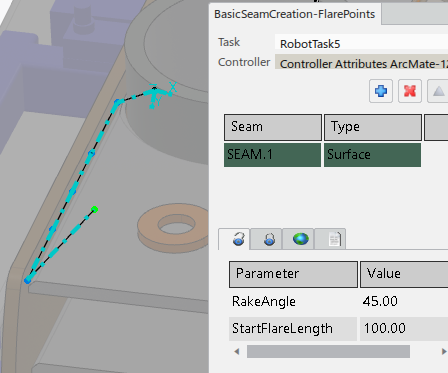

A panel appears that is titled based on the HEADER line of the loaded primitive file. It lists the created seams and parameters that were used in the process of seam creation. Parameters are displayed among four tabbed pages as follows.

Free lists parameters that can be modified.

Fixed lists parameters that are locked and cannot be modified.

Globals lists those parameters that are not defined in the primitive file, but whose default values are used to create a trajectory or task. These values cannot be modified.

WTS Display displays a section of the primitive file that was used to create the current seam. In the work area, a transient trajectory is created, and tags appear on the intersection of the selected surfaces.

After the points of a transient trajectory are created, a reach status analysis is performed. Reachable points are displayed in green. Points can also be out of limits (yellow), unreachable (red) or in clash (blue).

- Optional:

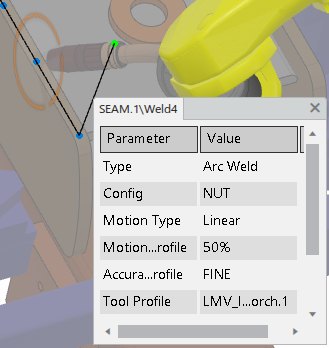

Select a point.

The robot moves to the point, and a panel displaying the properties of that point appears. The position, orientation and other motion properties of the points can be modified.

- Optional:

You can clone the seam and apply it to a different piece of geometry. The cloned seam has the same set of parameter values as the original seam.

- Click

.

. - Select additional geometry as you did in Steps 4-7.

Once geometry selection is complete, the new seam is created and appears in the list.

- Click

-

Click OK to generate the trajectory and task.

The new task(s) appear in the Behavior side tab.