Introduction

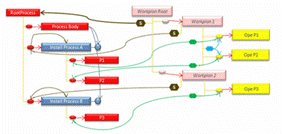

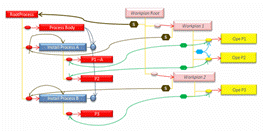

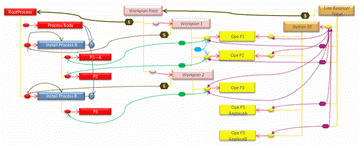

Final assembly workflow involves managing the exchanges between process planner, central planner, and line balancer.

The capabilities available for creating the required manufacturing assembly and system structures include:

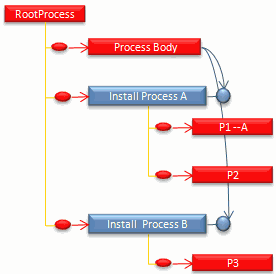

- Process planner has the possibility to create an item node called Manufacturing Installation. The Manufacturing Installation has an input that allows the user to specify on which body the items are installed.

- Central planner can create a Work plan system to manage the final assembly workflow.

- A Work plan system can have scopes to items but not scopes to systems.

- A Work plan system can have another Work plan system as a child. Other system types are not allowed as children.

- All types of operations can be created under a Work plan system.

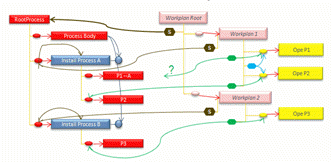

- Scope can be created between a Work plan system and a Manufacturing Installation.

- Scope can be created between a system and a Work plan system.

- All the system types except for a Work plan system can create a scope with a target Work plan system.

- If a system scope is created inside a root system, all the systems belonging to the root system cannot create an item scope.

- A root system containing a system that has a scope to a Work plan system is considered as a root system that belongs to a line balancer.

- Implement links between operations from central planner and operations from line balancer.