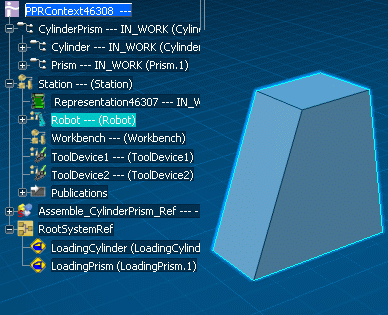

In this example, the content comprises a

Manufacturing Assembly on which there are associated parts (a cylinder and a prism). The item is assigned to operations (one for loading the cylinder, the other for loading the prism). Each part is realized by an

operation.

The parts are positioned with respect to a Robot resource.