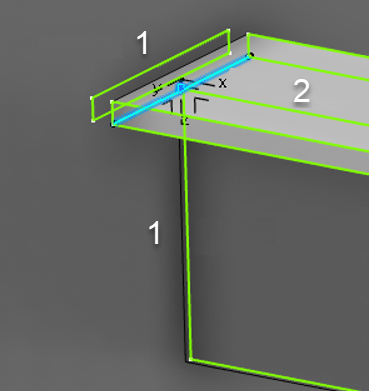

Weld Business Rule for Attachment and Alignment Line

This provides the openness in the Weld Business Rule to create an attachment line based on user-defined conditions.

Use the Weld Rule to determine whether the Attachment Line created or not. The Weld Rule defines in Data Setup and based on the Output of this, the Attachment Line then creates.

Example Weld Rule:

set fastenIPM = fastenProc.GetProcessOutput()

if (NULL <> fastenIPM)

{

set weldFeatures = fastenIPM.GetMfgFeatures("DELStrMfgWeldLine")

if (weldFeatures.Size()>0)

{

setmfgWeld = weldFeatures.GetItem(1)

if (NULL <> mfgWeld)

{

set weldLength = mfgWeld.WeldLength

if (weldLength > 50mm)

set bCreateAttachmentLine = true

else

set bCreateAttachmentLine = false

}

}

}

Parameters.SetAttributeBoolean("MarkingLinesForConnection", bCreateAttachementLine)

The Attachment line gets created based on the value given in the

MarkingLinesForConnection attribute.

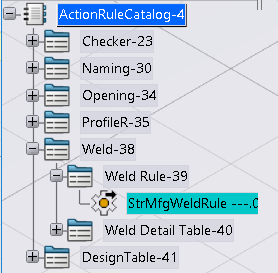

Define the Weld Business Rule in Data setup -> Structure Fabrication Resource -> Rules Catalog-> Weld-> WeldRule-> StrMfgWeldRule.

Define the Weld Rule from this example Weld Rule:

Behavior:

The Attachment line creates based on the Boolean return value of the MarkingLinesForConnection attribute defined in the weld rule.

The three cases:

- Update IPM: When update IPM executes, for the fasten process:

- The corresponding Weld line creates.

- The Weld Business Rule runs. If the return value is True for the MarkingLinesForConnection attribute, the Attachment line and Alignment line created. If the return value is False, they do not create.

- Edit Feature: In the Edit Feature command for the Assembly

level in the Connection tab, if adding a new Connection, then:

- The corresponding Weld line creates.

- The Attachment line and Alignment line complete, if the MarkingLinesForConnection attribute is False they do not create.

- Synchronization: During the Synchronization command after you

Compute, if there is a Weld Line creation:

- The Status and Action columns for the Attachment line, Alignment line, and Weld line, appear as New and Create respectively.

- After clicking Synchronize, the Weld line creates.

- During the Attachment line creation, the Weld Business Rule executes. And based on the MarkingLinesForConnection attribute value retrieved from the Weld Business Rule, Attachment Line creation occurs between connected processes in 3D. If the return value is True, the Attachment line creates. If the return value is False, the Attachment line does not create.