Shrinkage Synchronization | ||

| ||

- Panel Shrinkage Resulting Product - In the Panel Shrinkage Compensation

(SC) case, the SC resulting product, Manufacturing (Mfg) reps, and Mfg features have

been provided using the shrinkage planning command.

- Precondition: To have the correct behavior for

shrinkage synchronization, follow the below sequence:

- Part Planning - To create Mfg parts

- Weld Planning - To create Mfg manufactured item for fastener

- Update IPM - To create Mfg features

- Shrinkage Planning - To create a manufactured item, resulting product, and Mfg Rep for SC. As well as to transfer Mfg features from the resulting product of the manufactured part to the SC resulting product.

- If SC Mfg items are not properly existing before shrinkage synchronization, update for shrinkage synchronization does not support.

-

For 1 resulting product of the panel manufactured part, 1 SC a resulting product creates. The product includes the same quantity of SC Mfg Reps as the Mfg Rep of split plates in the resulting product of the panel manufactured part.

Each SC Mfg Rep has Mfg features transferred from the resulting product of the panel manufactured part. Therefore, any update of Mfg features in the resulting product of the panel manufactured part reflects in the SC the resulting product.

In the synchronization scenario case, when the panel designs data changes in SDD, the resulting product of the panel manufactured part synchronizes. This uses the Synchronization Manager.

The resulting product of the panel manufactured part synchronizes for the design change. Then the update of each Rep in the resulting product of the panel manufactured part applies to the SC resulting product.

Therefore, if a Mfg feature is not synchronizing in the resulting product of the panel manufactured part, the related SC Mfg features do not update.

- Precondition: To have the correct behavior for

shrinkage synchronization, follow the below sequence:

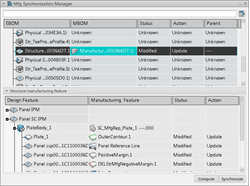

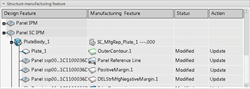

- User Interface - In this scenario, after computing panels

synchronization status, Panel SC IPM is listed as an

additional element. Under this element, SC Mfg Rep and features list with the same

structure as the resulting product of the panel manufactured part. Then the

Status and Action values for

themselves are displayed on the panel.

The SC resulting product is based on the resulting product of a panel manufactured part. So if the Action value for the resulting product of the panel manufactured part is defined as None, the SC resulting product cannot be synchronized.

- Shrinkage Synchronization - In the case of shrinkage synchronization,

three cases are supported. Such as new Mfg Rep and feature creation, Mfg rep and

feature deletion, and Mfg rep and feature modification in the resulting product of

the panel manufactured part.

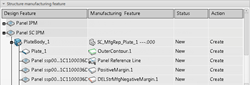

- Creation Case

- During the status computation, if a new Mfg Rep or feature in the resulting product of a

panel manufactured part create. A new SC Mfg Rep creation or feature

transfer requires in SC a resulting product.

Synchronization Manager shows New in Status and Create value in Action.

If you do not want an SC Mfg Rep creation or a feature transfer, select None value for Action. If not creating an SC Mfg Rep, features cannot create or transfer.

- During synchronization, an SC Mfg Rep creation and a feature transfer of which the

Action value is

Create are proceeded:

Some of the transferred features such as Outer Contour, Reference Line, and Opening are applied by default ratio value in the Shrinkage Rule in Data setup.

In a curved panel case, created SC Mfg Rep and features transfer to Flatten the resulting product.

- During the status computation, if a new Mfg Rep or feature in the resulting product of a

panel manufactured part create. A new SC Mfg Rep creation or feature

transfer requires in SC a resulting product.

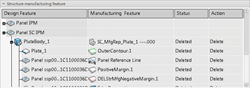

- Deletion Case -

- During status computation, sometimes the Mfg Rep or feature deletes in the resulting

product of a panel manufactured part. In this case, requires the SC

Mfg Rep or feature deletion in the SC resulting product.

Synchronization Manager shows Deleted in Status and Delete in Action.

Do not want the SC Mfg Rep or feature deletion, sometimes the origin Mfg Rep or, feature used for transfer in the resulting product of a panel manufactured part deletes. In this case, the transferred feature in the SC resulting products must delete. You cannot change the Delete value to None in the Action.

- During synchronization, the SC Mfg Rep or feature deletion of which the Action value is Delete are proceeded.

- During status computation, sometimes the Mfg Rep or feature deletes in the resulting

product of a panel manufactured part. In this case, requires the SC

Mfg Rep or feature deletion in the SC resulting product.

- Modification Case

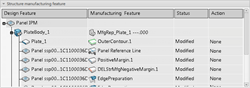

- During status computation, sometimes the Mfg feature modifies in the resulting product of

the panel manufactured part. In this case, the modification and

update for an SC Mfg feature transferred in the SC resulting product

requires.

The Synchronization Manager shows Modifiedin Status and Update value in Action.

Updating the SC Mfg feature, sometimes the origin Mfg Rep or feature used for transfer in the resulting product of the panel manufactured part updates. In this case, the transferred feature in the SC resulting products update. So you cannot change the Update value to None in Action.

- During synchronization, the update of the Mfg feature in the resulting product of a panel manufactured part reflects to relate to the SC Mfg feature. Even though the SC Mfg feature modifies, the ratio value applied to the SC Mfg features maintains.

- During status computation, sometimes the Mfg feature modifies in the resulting product of

the panel manufactured part. In this case, the modification and

update for an SC Mfg feature transferred in the SC resulting product

requires.

- Creation Case

- Weld Modification

In the case of an attachment line feature, selecting a weld product, an attachment line lists.

The following attributes can update: New, Modified or Deleted, and this occurs for the Attachment line in the Resulting product of the panel manufactured part. This results in the Attachment line, since the SC Mfg feature updates as mentioned in the above cases.