About Supporting Beam Fabrication | ||

| ||

Feature Creation

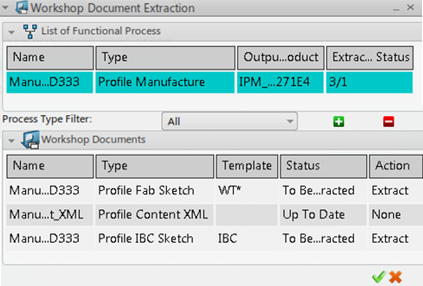

The following features support: BSU, Outer Contour, Attachment Line (On connected Plate), Alignment Line, Positive Margin, Edge Preparation, Manufacturing End cut, IBC, Feature transfer.

- BSU and Outer Contour Features: generated during update IPMs.

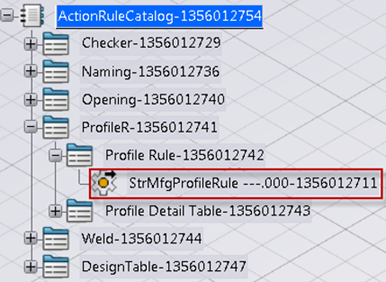

- Feature creation with Profile Rules:

- Features create on the beam after reading the Profile Rules defined in the PRM.

- These rules enable you to create the following features on the beam:

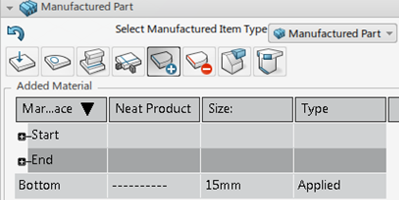

- Positive margins on the free faces of the beam (web start, web end, flange start, flange end, bottom).

- Negative margins on the free faces of the beam (web start, web end, flange start, flange end, bottom).

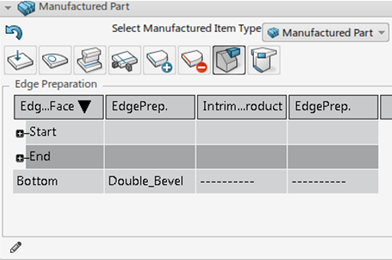

- Edge preparations on the free faces of the beam (web start, web end, flange start, flange end, bottom).

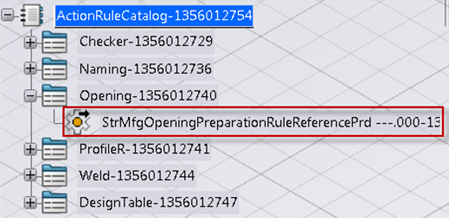

- Opening Rules:

Opening preparation completes on the profile as per the rule defined in the PRM.

- Feature creation with Weld Rules: SDD supports the following types of

welds, which involves a beam.

- Butt-Beam-Plate

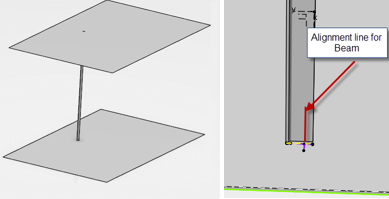

- In this case, the attachment line creates on the plate and the alignment creates on the beam.

- Also, depending on the weld rules, cutting features like edge prep, positive

margin, negative margin then places on the beam face, which has limits.

- Tee-Profile-Profile

- Butt-Profile-Profile

- Tee-Profile

- Butt-Beam-Plate

- Features created on the curved beam transfers onto the flattened beam.

- Roll lines generate on rolled beams.

- IBC generates for bent beams.

- Overlength creates on beams.

Feature Edition

- BSU is edited by changing to the BSU tab page.

- In the same tab page, the cutting length.

- The attachment line marked side and marking side can manipulate.

- Opening preparation for beams can edit through the opening preparation tab page.

- End cuts applied on the beam are in the end cut tab page.

- Margins can edit.

- If required, edit the Edge prep.