About Inter-Panel Split Plate Welding Fasteners | ||

| ||

Fastener Use Case Examples

- Marked ZeroPoint in a Profile Fab Sketch.

- Start Zero point

- End Zero point

- Plate and Exposed Split Plates

- Fastener 1: Between Plate1 and Plate 2.

- Fastener 2: Between Plate1 and Exposed Split Plate1.

- Fastener 3: Between Exposed Split Plate1 and Exposed Split Plate 2.

- Fastener 4: Between Plate 2 and Exposed Split Plate 1.

- Fastener 5: Between Plate 2 and Exposed Split Plate 2.

- Profile and Plates

- Fastener 1: Between Plate and Profile.

- Fastener 2: Between Exposed Split Plate2 and Profile.

Fastener Adoption and Propagation Support in a Weld Rule

- Propagation Mode Support - This provides the propagation mode for

Margin and Edge Preparation feature creation using the EKL Weld Rule. In the

case of Edge Preparation, the root gap applies with the Propagation Mode.

EKL weld rule supports Propagation Mode.

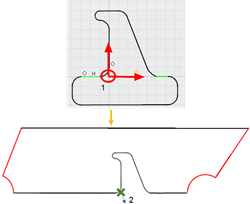

Origin of the catalog opening sketch. 1 - Origin of sketch, 2 - Origin of catalog opening sketch

Anchor Point in the profile fab sketch for the catalog opening - Joint attribute support - This provides a weld basis feature for

planning using the EKL weld rule. Weld Basis Features: Attachment Line,

Alignment Line, Margin, Edge Preparation. From SDD, the attribute is

introduced and replaces the attribute Weld type.

The new attribute of SDD Fastener, Joint, provides Tee, Butt and Lid types instead of Tee-Profile, Tee-Plate, Butt-Plate, and others of the old weld type. EKL weld rule includes with Joint attribute.

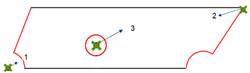

COG of Openings

Other openings in profile fab sketch.

1 - Start Zero point, 2- End Zero point, 3 - COG of Openings - EKL Weld Rule Enhancement - This enhances the EKL Weld Rule to

support Propagation mode and

Joint attribute.

In the EKL weld rule, WeldType variable has been provided for the old weld type. This enhances the existing WeldType variable by providing a Joint attribute value in the case of an enhanced SDD fastener.

In Joint attribute case, it provides connected type without Pilot and Joined products information.

For the propagation mode, apply None, Tangency Continuity and Point Continuity mode by giving a value in the EKL weld rule.

- None = 0

- Tangency Continuity = 1

- Point Continuity = 2

EKL Example:

MfgWeldType = MfgWeld.WeldType If(MfgWeldType == “Butt” || MfgWeldType == “Tee” || MfgWeldType == “Lid”) { IPM1=connectedProcess1.GetProcessOutput() IPM2=connectedProcess2.GetProcessOutput() Str_Prod1 = IPM1.GetStructureDesignObject Str_Prod2 = IPM2.GetStructureDesignObject IPM1_Code = “SQ_10_0” IPM2_Code = “SQ_10_0” IPM1_Propagation = 0 IPM2_Propagation = 1 IPMPropagationList.Append(IPM1_Propagation) IPMPropagationList.Append(IPM2_Propagation) IPMCodes.Append(IPM1_Code) IPMCodes.Append(IPM2_Code) IPMObjects.Append(IPM1) IPMObjects.Append(IPM2) } Parameters.SetAttributeObject("IPM", IPMObjects) Parameters.SetAttributeObject("Code", IPMCodes) Parameters.SetAttributeObject("PropagationMode", IPMPropagationList)