You can create a batch utility application to generate Plate

XML in a batch mode without launching 3DExperience, and it saves to the

database.

-

From the Tools section of the action bar,

select Utility

and

connect.

and

connect.

The Batch Monitor dialog box appears.

-

In the Utilities tab, select Heavy Industry

Manufacturing Options.

The application dialog starts.

-

Click the check box for Plate XML Operation.

-

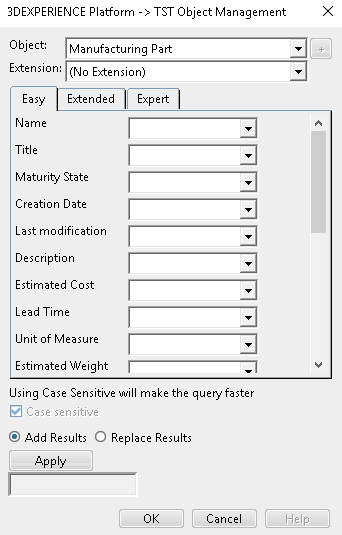

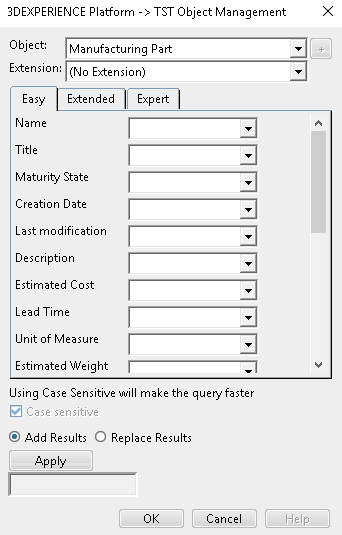

From the database using the 3DExeperience Platform Object

search, select objects.

The dialog box appears for selecting the manufactured part/assembly.

-

Select the Manufactured Part or

assembly as required in Object dialog

box.

-

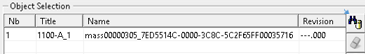

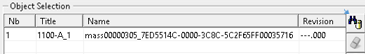

Click on Apply to search the required objects then click

OK to confirm the results.

The searched objects display in the batch extraction dialog.

-

Click Run to generate the Plate XMLs.

The generated XML's are saved to the database. For Manufacturing

Assembly, Plate XML's for all Plate Manufactured parts under selected

Manufacturing Assembly generate and save to the database.

The Report creates in the directory mentioned in the Report

Directory editor.