Zero Point in Built-In End-Cut

You can create Zero Point in the built-in end-cut by defining the parameters in the end-cut reference.

-

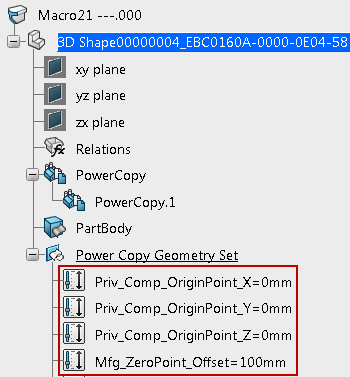

In Structure Design, before end-cut feature creation, create the parameters related

to Zero Point such as Priv_Comp_OriginPoint_X, Y and Z

and Mfg_ZeroPoint_Offset under the built-in end-cut.

Refer to the page Built-In End cut Parameters for the Origin Point parameters along with end cut parameters in 3D Modeling | Multi-Discipline Engineering | Structure Functional Design | Administration | Managing Endcuts | Built-In End Cut Parameters.

- Priv_Comp_OriginPoint_X

- Priv_Comp_OriginPoint_Y

- Priv_Comp_OriginPoint_Z

-

Create the Mfg_ZeroPoint_Offset parameter value manually, if

required.

During manufacturing end-cut feature generation,Zero Point parameters are generated under manufacturing end-cut features.

- Mfg_ZeroPoint_X

- Mfg_ZeroPoint_Y

- Mfg_ZeroPoint_Z.

Zero Point parameters are computed with profile origin and Mfg_ZeroPoint_Offset value.

-

Add the value of the 3 Priv_Comp_OriginPoint_X, Y and Z

parameters decided during the end-cut feature generation in Structure Design.

Gray Rectangle: Profile before applying end cut

Blue Rectangle: Profile after applying end cut

X: Zero Point (Profile Origin)

The initial value of the Zero Point parameters is the same as the profile origin. To make an accurate Zero Point position, the Zero Point based on the profile origin must be updated with the Mfg_ZeroPoint_Offset parameter. Therefore, move the Zero Point.

- For End-Cut features:

- Manufacturing End-Cut

During end-cut feature generation in Heavy Industry, manufacturing end-cut features are being generated with parameters. The values of parameters automatically calculate with an updated Zero Point in the built-in end-cut by applying offset.

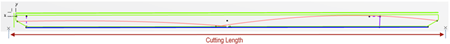

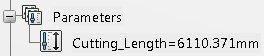

- Cutting length

During outer contour feature generation, profile cutting length is calculated. And the profile cutting length computation is basically based on the extremities of the profile. But if the Zero Point applies to the profile, the cutting length calculates using the Zero Points of the profile.

Note: Two Zero Points creates for information only, normally there are no geometric points.After the cutting length computation, this cutting length is define as a parameter.

If Margins, root gap and over length values creates at the start and end of the profile, it can make an impact on profile cutting length. So cutting length updates with these features values and the distance between the Zero Points.

Cutting Length = Distance between Zero Points + Positive margins - Negative margins - Root gap values + Over length values.

- Profile XML Extraction.

In the Mfg profile XML case, every profile information about cutting length, marking lines, texts, and others extract to XML. Distance computes from the Zero Point at the start of the profile.

For the cutting length in the generic profile XML, the value in the cutting length Parameter extracts.

- Manufacturing End-Cut