Reference Compensation Point for Tool Assembly Gauges | ||

| ||

Reference Compensation

The Reference Compensation option is defined

in the Tool Assembly tab

![]() in the

Tooling page

in the

Tooling page

![]() .

.

The Gauge values are defined for the specified tool compensation point (for example, P3).

When the active tool compensation point is different from the reference tool compensation point (for example, P4), then output parameters of the gauges are computed according to the tool insert geometry.

All insert types (round, diamond, square, triangular, trigon, and groove) are supported for computed parameters.

The Reference Compensation option is also available

for a Multi-Slide Lathe Tool Change in the Tool Assembly tab

![]() of the tool

change editor.

of the tool

change editor.

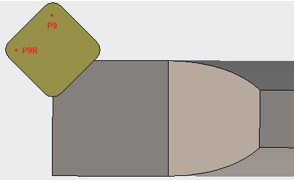

Example of Square Insert:

- Reference Z value defined for P8

- Computed Z value for P7

- Reference X value defined for P8

- Computed X value for P7

- P8

- P7

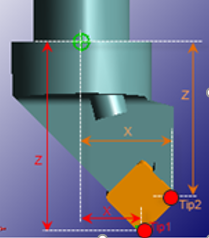

On the tool assembly, reference compensation is defined for P7 compensation point and gauges (set X, set Y, set Z values) are defined for this point.

When using another active compensation (Tool compensation

defined in Strategy page

![]() )

(P8 point), the computed X, Y, and Z gauges are output according to this

point (P8 point).

)

(P8 point), the computed X, Y, and Z gauges are output according to this

point (P8 point).

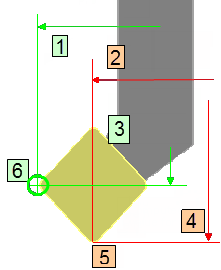

Example of Groove Insert:

- Reference Z value defined for P9 Left

- Computed Z value for P9 Right

- Computed X value for P9 Right

- P9 Right

- P9 Left

- Reference X value defined for P9 Left

On the tool assembly, reference compensation is defined for P9 Left compensation point and gauges (set X, set Y, and set Z values) are defined for this point.

When using another active compensation (P9 Right point), the computed X, Y, and Z gauges are output according to this point (P9 Right point).

Output File

The following parameters allow you to output the gauge values corresponding to the active tool compensation point. Compensation point creation dialog. Same will support for creating P9R compensation point over square insert.

- MFG_CMP_TL_SET_X: Computed Tool Assembly set length in X direction

- MFG_CMP_TL_SET_Y: Computed Tool Assembly set length in Y direction

- MFG_CMP_TL_SET_Z: Computed Tool Assembly set length in Z direction

- MFG_CMP_NOSE_RADIUS: Nose radius corresponding to the active compensation point (left or right). Nose radius could be different for groove insert (left radius, right radius), when changing the active compensation point automatically. For other inserts (diamond, square, and so on) the value is the insert radius.

These parameters are defined in NC_TOOL_CHANGE_LATHE or NC_CHANGE_REF_PT NC commands. For more information, refer to the PP Tables and Word Syntaxes - PP Word Tables.

Example of NC_CHANGE_REF_PT NC command defined in a PP word table:

SWITCH/%%MFG_TL_COMP,%MFG_CMP_TL_SET_X, %MFG_CMP_TL_SET_Y,%MFG_CMP_TL_SET_Z,%MFG_CMP_NOSE_RADIUS

Evaluation of the syntax:

SWITCH/9,55.000,0.000,23.000,0.5

These parameters are computed for the active tool compensation point defined on the turning operation according to the tool geometry.

The orientation of square inserts will enable two radii: P9 and P9R.

On the tool assembly, reference compensation is defined

for P9R for external and internal tools.

The Tool Definition panel for compensation point creation can be used to create a P9R compensation point over square insert.

Reference Compensation Point

When editing the tool assembly, the Reference Compensation option is initialized to P9 compensation point. This option is modified to define the reference compensation point for the set length values.

Previous parameters MFG_TL_SET_X, MFG_TL_SET_Y, MFG_TL_SET_Z, and MFG_NOSE_RADIUS still exist. Valuations are done according to the gauges defined on the lathe tool assembly (without any computation). The reference tool compensation point is not taken into account to compute these parameters.

Clicking the tab ![]() select More . This expands the dialog box. Click the Compensation tab. Here you can set to have the same definition of compensation point for milling and turning tool. Then we can display this parameter in APT file.

select More . This expands the dialog box. Click the Compensation tab. Here you can set to have the same definition of compensation point for milling and turning tool. Then we can display this parameter in APT file.

Right-click the type and the Compensation Definition dialog box appears. Adjust accordingly.

To allow the access to Corrector Id to print it in APT file. For this, we use a PPCommand MFG_ID_COMP.

For example, in your PPTable file, you have to define the following lines to access this parameter in your output APT file.

/

*START_NC_COMMAND NC_CHANGE_REF_PT

SWITCH/%MFG_QUADRANT,%MFG_TL_COMP,%MFG_ID_COMP

*END

/

Find the definition of all PPCommand in DELMIA | Machining | NC Machining Apps Common Services | Reference Information | PP Tables and PP Word Syntaxes | Other NC Commands.