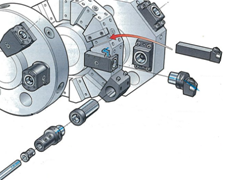

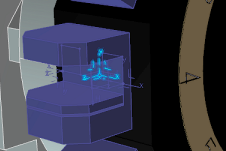

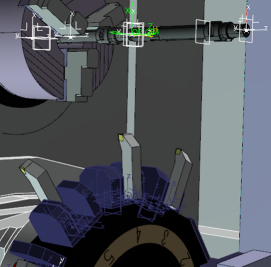

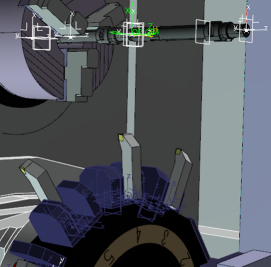

This shows how the mounted tool can take part in machining.

The Tool which is defined on Mount location 4 is index to participate in machining as oriented as shown.

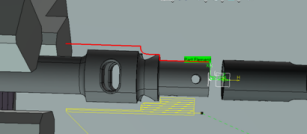

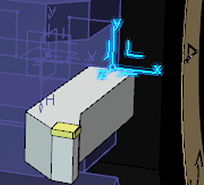

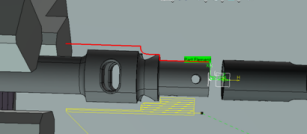

If the tool orientation is observed, it matches this. But the orientation is not the desired one and the toolpath is not acceptable.

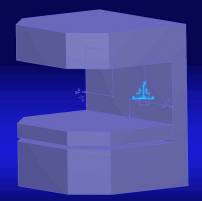

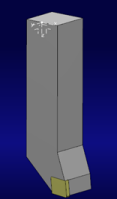

We need to add a tool invert to get the desired orientation. In the dialog box, under Geometry tab, select to activate Tool Inverted. If we update positions, the tool orientation is changed in the configuration manager.

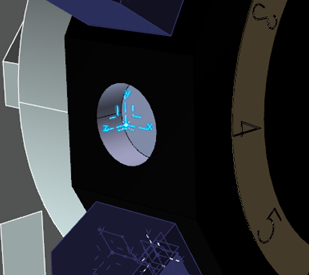

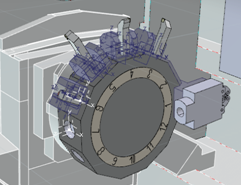

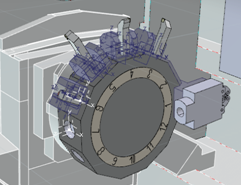

Here is how the mounted tool can take part in machining after applying the tool invert parameter. The Tool which is defined on Mount location 4 is indexed to participate in machining as oriented as shown.

Compute the toolpath again and the tool orientation and hence the toolpath is the desired one.