Basic Concepts

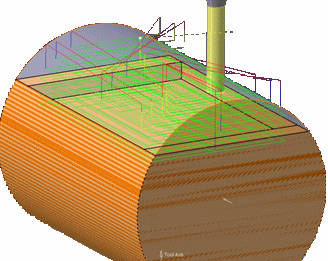

Input and output intermediate stock is created and visualized for all types

of machining operations (mill, drill, and turn).

Note:

A manufacturing program can mix different types of machining operations. Example, a milling operation is allowed after a turning

operation and a turning operation is allowed after a milling operation. Lathe

operations are mixed with milling operations.

The intermediate stock is taken into account to optimize and

compute a collision free tool path in the

computation of roughing, axial, prismatic, and selected

mill-turn machining operations.

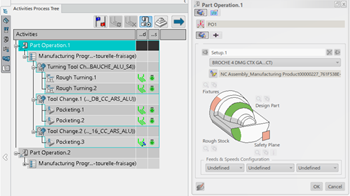

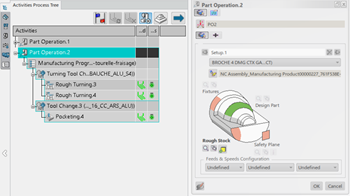

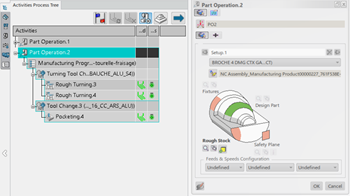

The intermediate stock capability is enabled by selecting the Activate the

Intermediate Stock check box in the Options tab

of the Part Operation dialog box.

Note:

If several setups have been defined in the Setup tab of the Part Operation dialog box, only the machining operations that use the same setup position are taken into account when computing the

intermediate stock. The first machining operation always uses the rough stock defined in the associated setup position.

Activate the Intermediate Stock deals with:

- Input Intermediate Stock

- Solid corresponding to the

machined part before the machining operation.

- Output Intermediate Stock

- Solid corresponding to the

machined part after the machining operation.

- Input Stock Contour

- Profile corresponding to

the maximum turning envelope of the Input Intermediate

Stock.

- Output Stock Contour

- Profile corresponding to the maximum turning envelope of the

Output Intermediate Stock.

- Stock Synchronized with the Operation

- To manage the

lifecycle, the rough stock is linked to a specific version of the tool

path of the machining operation. If the tool path is changed, the rough stock is no longer

synchronized.

Notes:

- The input stock of a machining operation is the output stock of the previous machining operation associated to the same setup position. In the case of intermediate

stock and multi-turrets, the previous machining operation is defined by taking into account the synchronization between the

different programs.

- The intermediate stock bodies and contours are stored in the manufacturing cell.

- The PPR Context must be linked to a product, and a stock must be clicked

in the setup position.

Visualization Recommendations

Using several settings improves the visualization of intermediate stock.

They

are:

-

to manage the color and the transparency of the intermediate

stocks.

-

:

- The Transparency Quality must be defined as

High (Alpha Blending) to visualize the

transparency variations,

- The Pixel Culling

(Static and While

Moving) must be defined as 0 for a correct display

of the intermediate stock contour that is computed while editing

turning machining operations.

Intermediate Stock Commands in Machining Operations Dialog Boxes

Intermediate Stock in Turning Operations

Input and output stock is computed on any turning operation.

Note:

When Activate the intermediate stock check box is

selected, these conditions occur:

- An input stock contour is used as the

default rough stock of the machining operation.

- The stock contours are created by computing the maximum turning envelope of

the intermediate stock, ensuring that stock contours are computed from

nonsymmetrical stock bodies.

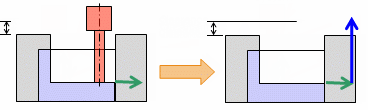

Intermediate Stock in Axial Operations

All axial machining operations (Drilling, Spot Drilling, Circular Milling) support intermediate stock.

- Drilling Point

- A drilling entry point is computed on

the stock.

- If this computed drilling entry point (1) is above the selected

one, it replaces the selected one (Stock (2), Part (3)).

- If a Top element is selected and the

computed point is above the Top element,

the Top element is not taken into

account.

- Linking motions

-

- The linking motions (1)

between drilling points are computed according to the

intermediate stock (4). (Clearance distance on stock (2), Approach clearance (3)).

- The linking macro motion is done up to the intermediate stock.

- Collisions are checked with the tool along the linking motion.

- The Stock

clearance defined in the Part Operation is used to define a motion without collision with the current

stock.

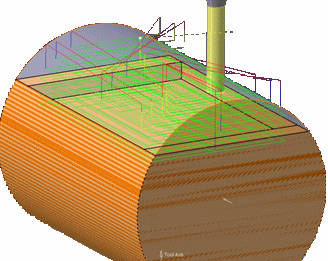

Intermediate Stock in Milling Operations

Intermediate stocks are supported by milling operations.

The

top plane of the intermediate stock is

automatically computed in the machining area by relimiting the input stock with

the machining area:

- If there is no user-defined plane, the automatically computed plane defines

the top plane of the machining operation.

- If a user-defined plane is defined, it is taken into account if it is higher

than the automatically computed plane along tool axis direction.

All milling operations support intermediate stock. However, the following machining operations support intermediate stock and automatic top plane computation:

- Pocketing

- 4-Axis pocketing

- Facing

- Profile contouring

- Prismatic roughing

- Roughing

- Plunge milling

- Cavities roughing

- Trochoid milling

The following machining operations support intermediate stock and tool path optimization:

- Pocketing

- 4-Axis pocketing

- Facing

- Profile contouring

- Prismatic roughing

- Roughing

- Plunge milling

- Cavities roughing

- Trochoid milling

- Multiaxis curve machining

Intermediate Stock in Pocketing Operations, 4-Axis Pocketing Operations, Profiling

Operations, and Multi-Axis Curve Machining Operations

Intermediate stock is used in Pocketing Operations, 4-Axis Pocketing Operations,

and Multi-Axis Curve Machining Operations to avoid air cutting.

On each level, the

machining area is delimited by the stock, to avoid air cutting passes.

The tool path is optimized to avoid air cutting.

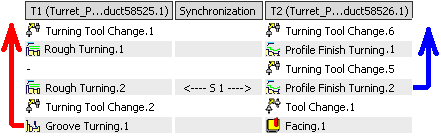

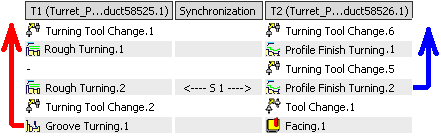

Intermediate Stock and Multi-Turrets

Intermediate stocks are not computed in the same way when manufacturing programs are synchronized between multiturrets.

When manufacturing programs are sequential, the input intermediate stock is computed from the tool paths of

the previous machining operations.

The previous machining operations for a given machining operation are:

- All the machining operations in the previous programs.

- All the machining operations between the program start and the given machining operation in the current program.

For example:

- The computation of the input intermediate stock of Groove

Turning.1 takes into account the tool paths of

Rough Turning.2 and Rough

Turning.1.

- The input stock of Profile Finish Turning.2 is

computed from the tool paths of Profile Finish

Turning.1, Groove Turning.1,

Rough Turning.2, and Rough

Turning.1.

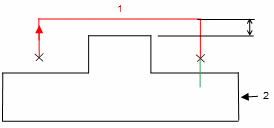

If several manufacturing programs are synchronized between multiturrets, the manufacturing programs are no longer sequential but run in parallel. For example:

In this case, when synchronization occurs in the process, the computation

of the intermediate stock:

- Takes into account all the previous machining operations of the same program (red arrow),

- Considers the last synchronization before the current machining operation and takes into account all the machining operations defined before this synchronization (blue arrow). According to the type

of synchronization, the synchronized machining operation is taken into account, which is when the synchronization targets the end

or the retract macro. Or when the synchronized

machining operation is not taken into account, which is when the synchronization targets the

start or the approach macro.

- The previous machining operations for Groove Turning.1 are:

- Rough Turning.2 and Rough

Turning.1 (in the manufacturing program corresponding to turret T1).

- In the program corresponding to turret T2:

- Profile Finish Turning.1 and

Profile Finish Turning.2 (if the

synchronization S1 targets the end or the retract macro of

Profile Finish Turning.2).

- Profile Finish Turning.1 only (if the

synchronization S1 targets the start or the approach macro

of Profile Finish Turning.2).

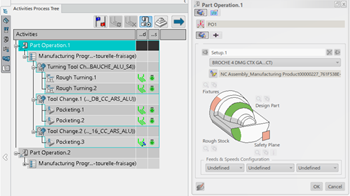

When there are several synchronizations, only the initial synchronization of the machining operation is taken into consideration. For example:

In this case, the initial synchronization is synchronization S3. Thus, the

previous machining operations for Pocketing.1 are:

- Groove Turning.1, Rough

Turning.2, andRough Turning.1 (in the

program corresponding to turret T1).

- In the program corresponding to turret T2:

- Profile Finish Turning.1, Profile

Finish Turning.2 and Facing.1

(if the synchronization targets the end or the retract macro of

Facing.1).

- Profile Finish Turning.1, Profile

Finish Turning.2 only (if the synchronization

targets the start or the approach macro of

Facing.1).

Notes:

- When a machining operation is considered as a previous one, its whole tool path is taken into

account for the computation of intermediate stock.

- In the case of a synchronization before a retract macro, the whole

tool path of the synchronized machining operation is taken into account for the computation of the intermediate

stock.

- In the case of a synchronization after an approach macro, the whole

tool path of the synchronized machining operation is not taken into account for the computation of the intermediate

stock.

- In the case of synchronized manufacturing program, the determination of the list of machining operations (from the other program) occurring before the current machining operation relies on the last synchronization defined before the current machining operation (and does not rely on time-based information). Some machining operations of the other program may not be taken into account in the machine

position.

- In the case of a synchronization before a retract macro, the whole tool

path of the synchronized machining operation is taken into account for the computation of the intermediate stock.

- In the case of a synchronization after an approach macro, the whole tool

path of the synchronized machining operation is not taken into account for the computation of the intermediate stock.

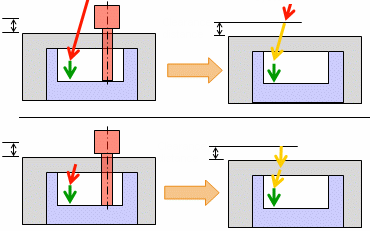

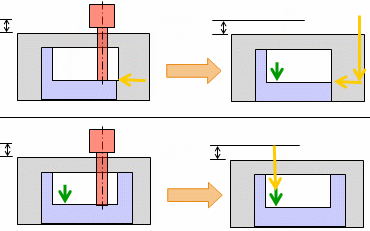

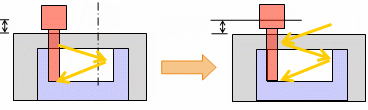

Intermediate Stock and Macro Motions

Intermediate stock is processed within macro motions.

There is

no RAPID motion inside the intermediate stock. Macro motions are managed to avoid

RAPID tool motion inside the material.

Macro motions are automatically updated when a collision (in RAPID mode) is detected

with the cutter during tool path computation by:

- Automatic extrapolation of macro motion

- Automatic feedrate modification.

In the examples below, the various feedrates are represented as follows:

- RAPID - Red arrow

- Approach - Yellow arrow

- Retract - Blue arrow.

- Machining - Green Arrow.

To get valid linking motions in all machining operations (except in rough turning

operations), activate intermediate stock to manage the stock in the tool path

computation.

Intermediate Stock Lifecycle

The lifecycle of intermediate stocks is followed by their status.

- Status of the input intermediate stock

- The

input intermediate stock status is up-to-date:

- If the input intermediate stock is already computed.

- If all previous machining operations have a tool path and are up-to-date or have a locked tool path.

- If all previous output Intermediate stocks are synchronized with the

machining operations.

- If the stock assigned in the part operation has not changed.

In all other cases, the input intermediate stock is not up-to-date.

- Status of the Output Intermediate Stock

- The output intermediate stock status is up-to-date:

- If the output intermediate stock is already computed.

- If the machining operation has a tool path and is up-to-date or has a locked tool path.

Intermediate Stock Management

When the intermediate stock has two positions to machine on both sides, you must

create two part operations with one setup position. In this case, you must automatically

specify the computed output intermediate stock of the last operation associated with the

previous setup position as input stock of the setup position.

- Part and Stock Defined

- When the result of material removal is exported at the end of the first

setup position, the material removal must be defined as starting stock in

the second setup position even if the intermediate stock is activated.

- There is no restriction on the number of setups that you can have if you

define them on same NC Assembly. There is also no restriction on the number

of programs you can have in setups since it allows all operations from all

programs.

- In this case, the output stock of the last operation is the input stock of the setup

position.

If the previous operation has output stock

deactivated, the system searches for the last valid output stock on previous

operations.

- Part Defined Without Stock Defined

- Sometimes the intermediate stock is activated and no stock is selected in the setup

position. In this case, the computed intermediate stock of the last

operation associated to previous setup position is used as stock of the next

setup position.

- If no valid operation is found in the other previous setup position (in case there are no

operations or operations have locally deactivated the output stock

computation), then the stock defined in the previous setup position is used

if available.

- In case of several NC Machines, the previous intermediate stock is searched also on

previous NC Machine programs, with respect of NC Machine ordering created in

machining cell.

As no stock is defined on SetupPosition.2,

the intermediate stock is retrieved from end of Machining

Operation.1

- This behavior is only available in the following scenarios:

- If the intermediate stock is activated on all part operations.

- If at least two setup positions have been created in the same machining cell in one or

several part operations.

- If the NC assembly selected in setup position is the same reference, where there is one

instance of the same reference for each setup position.

- Activated Stock with Stock Selected in Setup

- If the intermediate stock is activated and the previous setup position is on the same NC

Assembly and has a stock defined, then the stock selection is optional. In

this case, an icon

is displayed to compute and display the input intermediate stock inherited

from the previous setup position.

is displayed to compute and display the input intermediate stock inherited

from the previous setup position.

- If any operations from the first setup are modified, then all operations of

next setup position are defined as not up-to-date. In this case, you must

recompute the Tool Path based on the new input stock.

|