Effects of Reversing Machining Conditions | ||

| ||

| Machining Operation | Effect of Reverse Machining Conditions |

| Prismatic Roughing | Climb and Conventional options are inverted |

| Profile Contouring | Climb and Conventional options are inverted

Order of multi-contours is inverted. Start and End elements, offsets are inverted |

| Facing | Climb and Conventional options are inverted |

| Pocketing | Climb and Conventional options are inverted |

| Plunge Milling | Nothing to reverse |

| 4-Axis Pocketing | Climb and Conventional options are inverted |

| All Axial Machining Operations | Order of pattern points is inverted |

| Tslotting | Climb and Conventional options are inverted |

| Circular Milling | Climb and Conventional options are inverted Order of pattern points is inverted |

| Sequential Axial | Order of pattern points is inverted |

| Slot Milling | Climb and Conventional options are inverted |

| Groove Milling | Climb and Conventional options are inverted Inversion of Geometry points |

| Sequential Groove | Climb and Conventional options are inverted for circular and helical motion |

| Thread Milling | Order of pattern points is inverted |

| CUTCOM | You should check that the desired cutter compensation is still applied (correct side, and so on). |

| Roughing | Climb and Conventional options are inverted. |

| Cavities Roughing | Climb and Conventional options are inverted |

| Sweep Roughing | Start direction is inverted |

| Power Machining | Climb and Conventional options are inverted |

| Advanced Finishing | Climb and Conventional options are inverted |

| Contour Driven | Tool Path is inverted |

| 4-Axis Curve Sweeping | Start direction is inverted |

| Sweeping | Tool Path is inverted |

| Pencil Machining | Climb and Conventional options are inverted |

| Zlevel | Climb and Conventional options are inverted |

| Spiral Milling | Climb and Conventional options are inverted. |

| Isoparamametric machining Operations | Order of parts is inverted. Corners 1 and 2 are swapped. Corners 3 and 4 are swapped. Corresponding interpolation axes at corners are swapped. |

| Multi-Axis Isoparametric Machining | Pole points are inverted |

| Multi-Axis Sweeping | Start direction is inverted |

| Multi-Axis Contour Driven | Start direction is inverted |

| Multi-Axis Spiral Milling | Climb and Conventional options are inverted |

| Multi-Axis Tube Machining | Way of cut (clockwise/counter) is inverted |

| Multi-Axis Helix machining | Climb and Conventional options are inverted |

| Multi-Axis Curve Machining | Climb and Conventional options are inverted Geometry points are inverted Sign of Tilt angle is changed to invert the left/right condition Couple of Points limit elements are swapped.For Tangent Axis guidance along isoparametric lines: when machining a strip of drive surfaces, check that the reference tool axis gives the desired result for the best matching u or v isoparametric line of the first machined face. |

| Multi-Pockets Flank Contouring | Climb and Conventional options are inverted |

| Multi-Axis Flank Contouring | Geometry parameters are inverted |

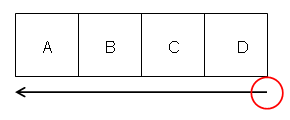

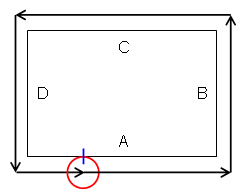

| Multi-axis Flank Contouring | Climb and Conventional options are inverted Order of drives is inverted as follows when the Close tool path check box is not selected. Drives A, B, C, D are machined in the order D, C, B, A.

Order of drives is inverted as follows when the Close tool path check box is selected. Drives A, B, C, D are machined in the order A, D, C, B, A. Drive A is the first and last machined element.

Start and End elements, offsets, and conditions are inverted. Approach and Leave distances are swapped. Manual direction is inverted (Left / Right). Local stopping condition and Local restarting direction are updated. |