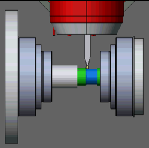

Case 1, Two Setups : 1 > 2

This describes a Machining Setup.1, then Setup.2.

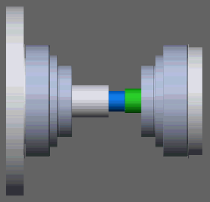

The Initial condition is:

- Setup.1 is attached

- Setup.2 is detached

The steps for:

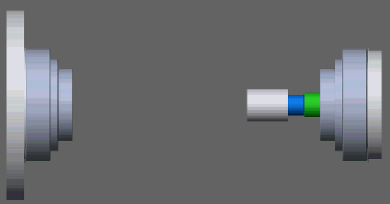

- Machining of Setup.1

- Programming of Setup.1

- Part Sequencing of Setup.1

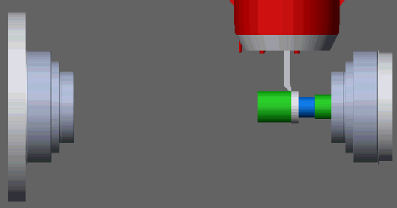

- Move the counter spindle

- Attach the Setup to the counter spindle

- Detach the Setup to the main spindle

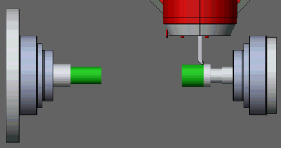

- Move the counter spindle to move stock from Setup.1 to Setup.2

- Move the counter spindle

- The Machining Actions for Setup.2

Actions Ref

Name Type Attachments Device Product Position 1 Move to Setup.1 Motion CounterSpindle 2 Attach to Counter Spindle Attach Attach CounterSpindle Setup.1 3 Detach to Main Spindle Attach Detach MainSpindle Setup.1 4 Move to Setup.2 Motion CounterSpindle

Expected Simulation:

- Only one stock is shown

- The programming Setup.1 and Setup.2 machine the same stock