Concepts of Engineering Connections for Mounting | ||||

|

| |||

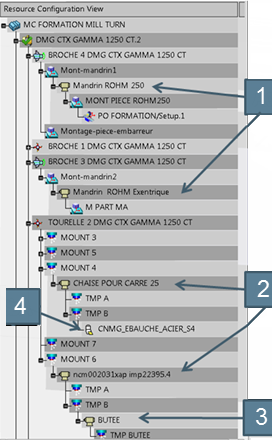

Old data is migrated by creating Engineering Connections (EC), provided the data contains accessories, adapters or tools already mounted in it. MfgMachineConfiguration feature is replaced by Engineering Connection of type Rigid.

| Resource and port on which mounting will happen | Resource to be mounted along with its port | Engineering Connection of Rigid type |

|---|---|---|

| WMP on machine | Accessory having Mechanical Port of type Base Port or Head Base Port | Between the machine element containing WMP and the accessory. |

| WMP on accessory | Another accessory having Mechanical Port of type Base Port or Head Base Port | Between the two accessories |

| TMP on machine | Adapter having Mechanical Port of type Base Port or Head Base Port | Between the machine element containing TMP and the adapter. |

| TMP on adapter | Another adapter having Mechanical Port of type Base Port or Head Base Port | Between the two adapters. |

| TMP on machine | Tool Assembly having Base Port | Between TMP of Machine and Base Port of Tool Assembly. |

| TMP on adapter | Tool Assembly having Base Port | Between TMP of adapter and Base Port of Tool Assembly. |

If old data consists of mounted resources (accessories, adapters or tools) then during opening it gets migrated or upgraded by replacing MfgMachineConfiguration feature for each mount with a Engineering Connection.

- Accessories mounted on machine.

- Adaptors mounted on machine.

- Adaptor mounted on adaptor.

- Tool assigned on adaptor.

A Engineering Connection is always created between Base Mount Point and Workpiece / Tool Mount Point.