Content According to Macro Mode

The dialog box can have different looks, according to the macro definition mode.

Load from Catalog: load a macro from an existing catalog. Save in Catalog: save a macro in catalog.

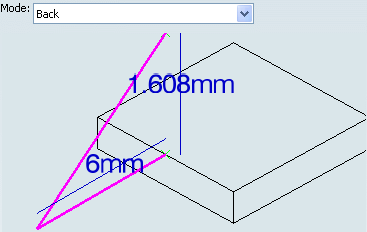

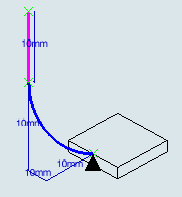

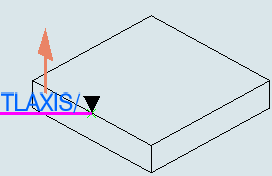

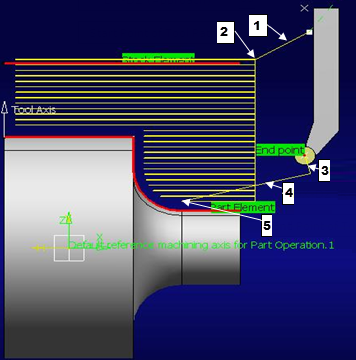

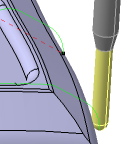

- In the Back Graphic Mode:

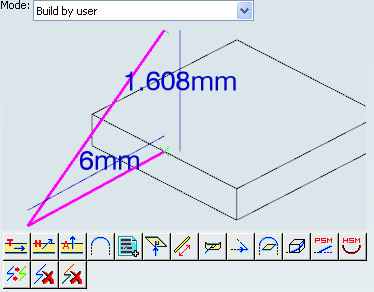

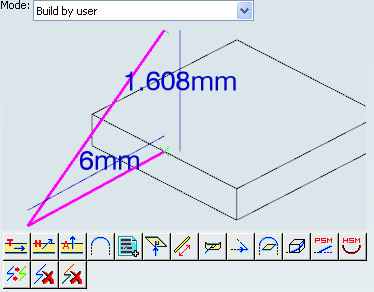

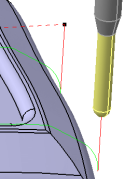

- In the Graphic Mode, using the Build by user macros:

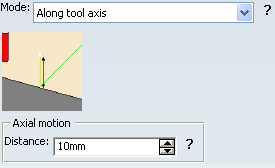

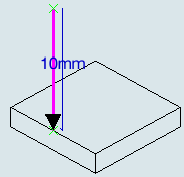

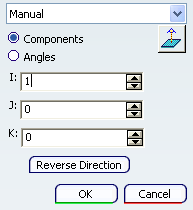

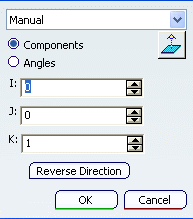

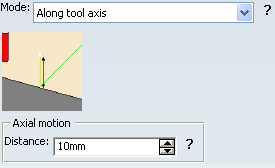

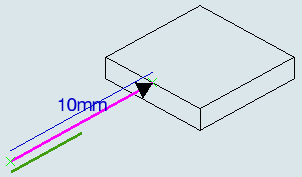

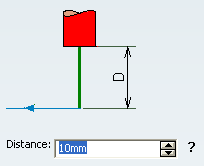

- In the Numeric Mode Along tool axis:

With the pointer in the view section of the dialog box, you

can:

- Zoom in and out and pan the paths.

- Place your pointer on a portion of the macro path and right-click.Delete and Insert are available for the

Build by user macros.

Note:

The graph displayed in the viewer of the dialog box is a generic representation of a

macro mode. It is not the true representation of the macro you are using or defining. To

check the result of your settings, click Display or

Simulate.

Macros Parameters

You can define macros with the following parameters.

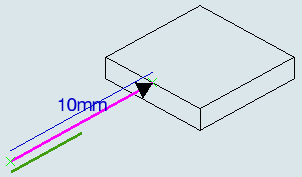

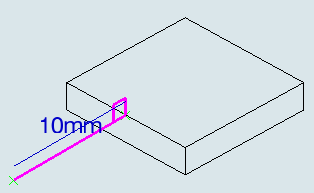

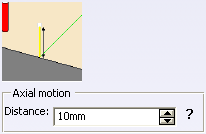

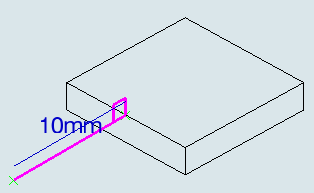

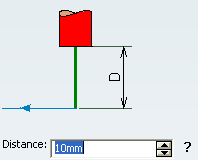

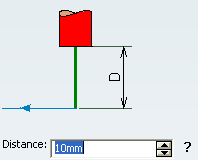

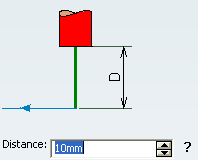

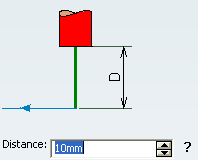

Along a Vector

The tool moves along a vector (line motion) for a given

Distance,

In Graphic Mode:

- Double-click the magenta line to edit the Distance

along the line motion,

- Double-click the green line to edit the direction.

In Numeric Mode:

- Type the Distance value.

- Select Direction to edit the vector direction.

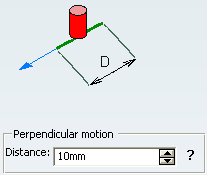

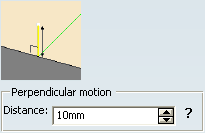

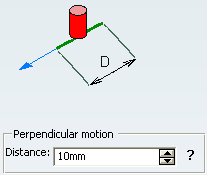

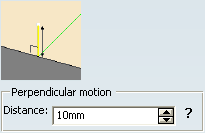

Normal The tool moves in a direction

perpendicular to the surface being machined ( Perpendicular

motion), for a given Distance.

In Graphic Mode, double-click the magenta line to edit the distance in the Perpendicular

motion.

In Numeric Mode, enter the Perpendicular motion Distance.

None No approach nor retract macro is applied.

Note:

When this macro is selected on Approach or

Retract, no Link to Safety Plane is added, as shown

below.

If you require a Link to Safety Plane, select Along tool

axis with an Axial motion Distance value equal to

0 mm. Results:

(This is not available with an Isoparametric Machining Operation.)

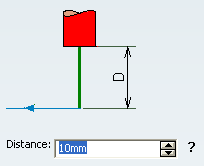

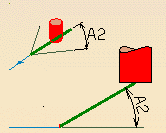

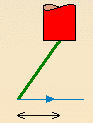

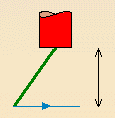

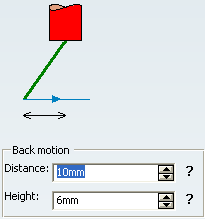

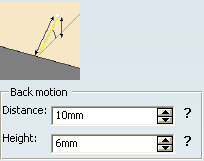

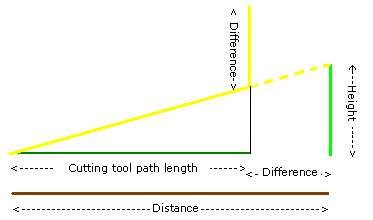

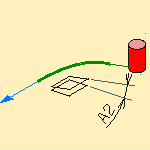

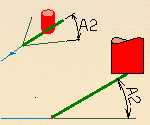

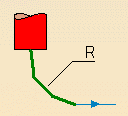

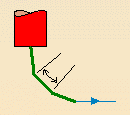

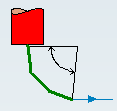

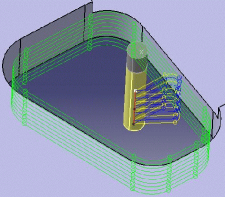

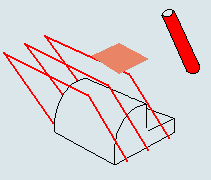

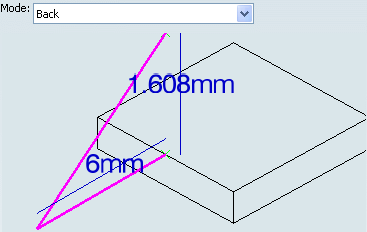

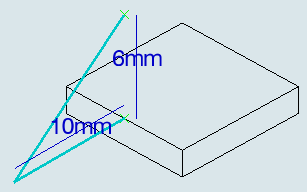

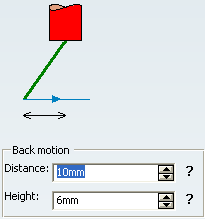

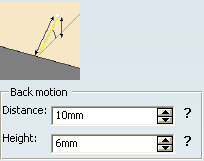

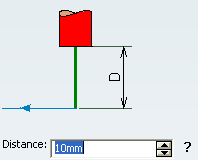

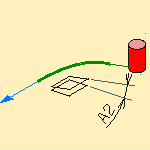

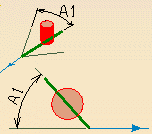

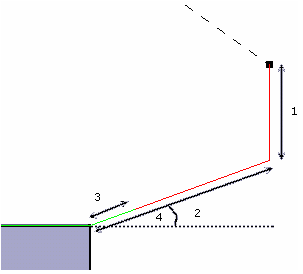

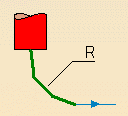

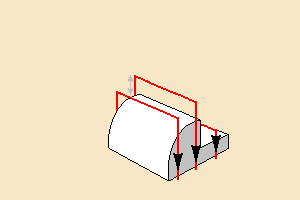

Back The tool doubles back like an arrow above the cutting tool path

(Back motion).

You can either define this type with a Distance

and a Height.

In Graphic Mode, double-click the magenta line to edit the

Distance and the Height.

In Numeric Mode, type the Distance and the

Height.

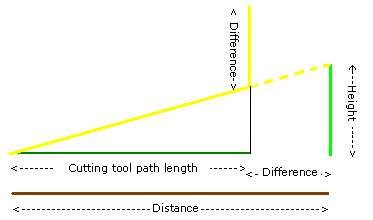

Note:

When you enter a Distance higher than the cutting tool path to which

the macro refers, a tool path Along Tool Axis is added. In this

case, the length is equal to the difference between Distance and

the length of the cutting tool path.

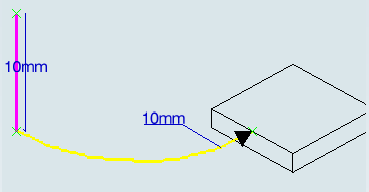

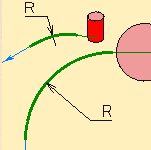

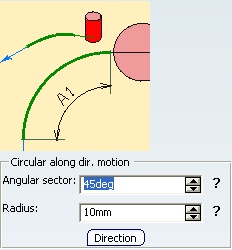

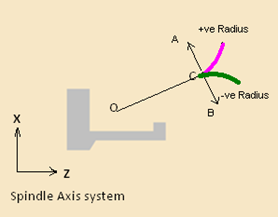

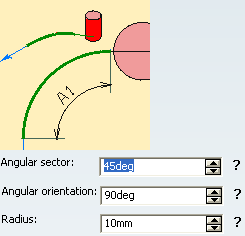

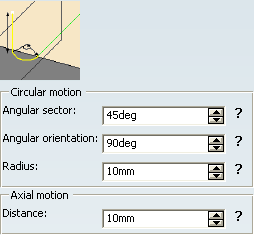

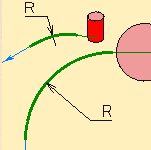

Circular The tool moves towards/away from the part in an arc (circular

motion).

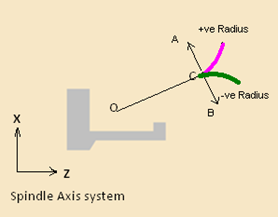

The following conventions apply: - For the Radius:

Given the spindle axis as shown in the picture,

the line OC is the toolpath or a macro before the

Circular macro. - A positive radius (shown as +ve) positions the arc as shown in pink, with the center A to the left of

the line OC.

- A negative radius (shown as -ve) positions the arc as shown in green, with the center b to the right of

the line OC.

Note:

The arcs produced are always smooth with

respect to the preceding line meaning such a case is not valid:

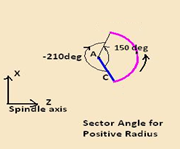

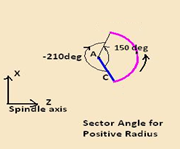

- For the Angular sector with a positive radius: Given the spindle axis as

shown,

a positive Angular sector (+ ve ) produces a

counterclockwise direction of the circular arc for the Retract macro. Then it produces a clockwise direction

of the circular arc for the Approach macro.Note:

For a positive radius, all the

negative angles are converted to the equivalent positive angles. The picture shows

an example for 150 degrees and -210 degrees. Since here -210 is equivalent to +150,

the arc produced in both these cases is essentially the same (the pink arc).

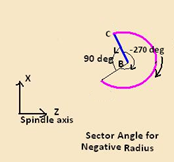

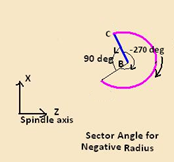

- For the Angular sector with a negative radius: Given the spindle axis as

shown,

a negative Angular sector (- ve ) produces a

clockwise direction of the circular arc for the Retract macro. It also produces a

counterclockwise direction of the circular arc for the Approach macro.Note:

For a

negative radius, all the positive angles are converted to the equivalent negative

angles. The picture shows an example for 90 degrees and -270 degrees. Since here 90

is equivalent to -270, the arc produced in both these cases is essentially the same

(the pink arc).

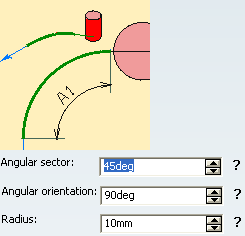

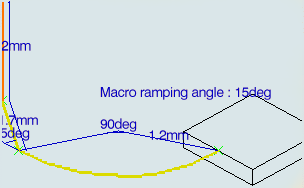

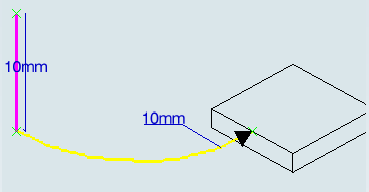

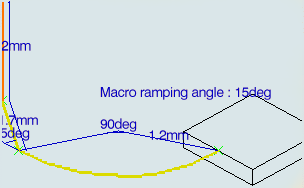

In Graphic Mode:

- Double-click the arc (yellow line) to edit the circular

motion:

- Double-click the magenta line to edit the Axial motion

Distance.

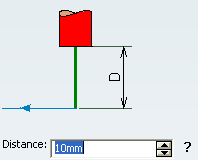

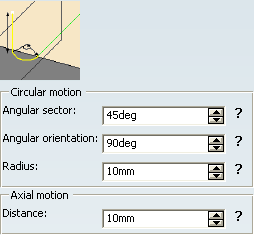

In Numeric Mode, enter the Angular sector, the Angular

orientation, the Radius, and the Axial

motion

Distance.

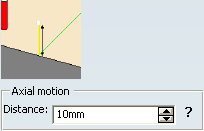

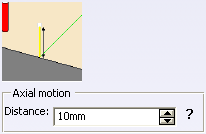

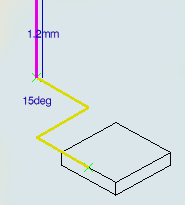

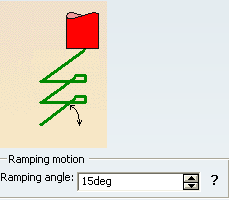

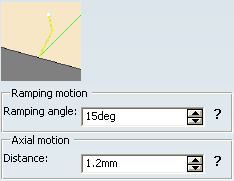

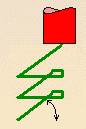

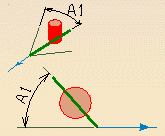

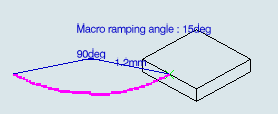

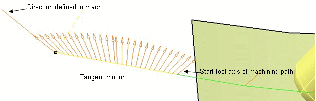

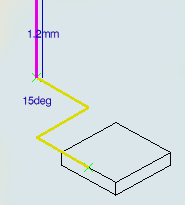

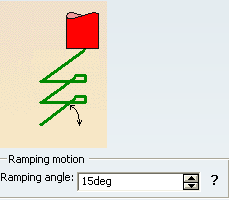

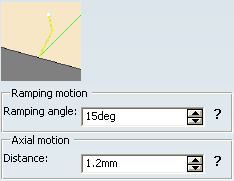

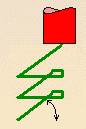

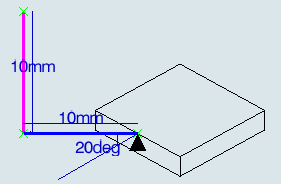

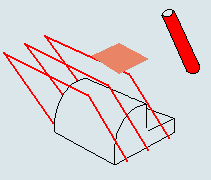

Ramping The tool follows a slope defined by the ramping angle.

The parameters to define are the Axial motion Distance

and the Ramping angle.

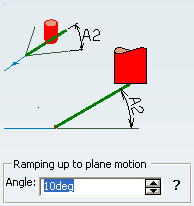

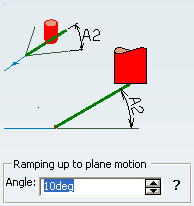

In Graphic Mode:

- Double-click the magenta line to edit the Axial motion

Distance:

- Double-click the yellow line to define the Ramping

angle:

In Numeric Mode, enter the Ramping angle and the Axial

motion

Distance.

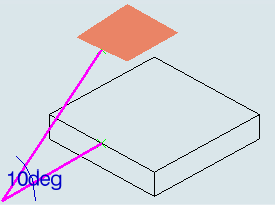

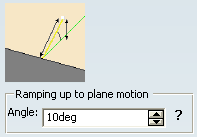

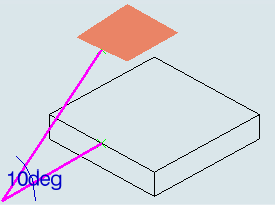

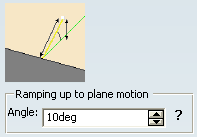

Ramping up to Plane The tool follows a slope defined by the ramping angle up to a plane. In Sweep Roughing,

Sweeping, 4-Axis Curve Sweeping, Pencil, Contour Driven Machining, Spiral

Milling, Multi-Axis Spiral Milling, and Multi-Pockets Flank

Contouring Machining Operations, the slope no longer goes down when the tool

path does and prevents plunges into the material. The parameters to define are the Angle and the plane.

In Graphic Mode, double-click the Angle to define it:

and click the plane to select one.

In Numeric Mode, enter the Angle:

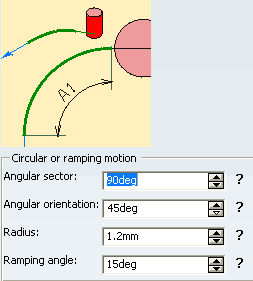

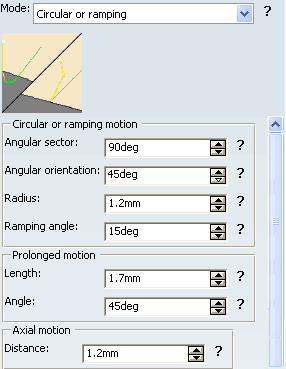

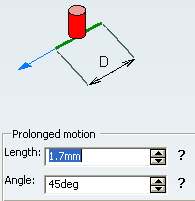

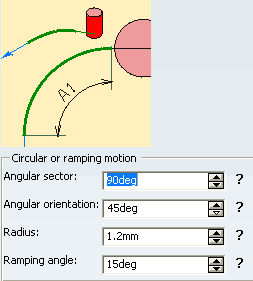

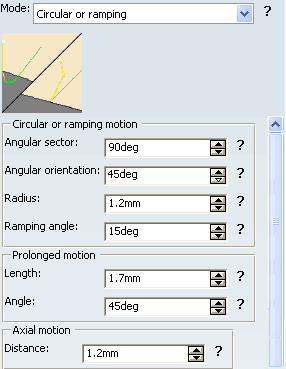

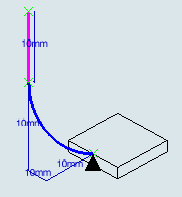

Circular or Ramping The tool uses either circular or ramping mode depending on

whichever is best adapted to the part being machined.

The Circular or

ramping motion is defined by:

- Angular sector,

- Angular Orientation,

- Radius,

- Ramping angle,

The Prolonged motion is defined by:

- Length,

- Angle,

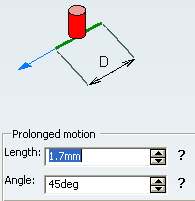

In Graphic Mode:

- Double-click the orange line to edit the Axial motion

Distance:

- Double-click the inclined yellow line to edit the

Prolonged motion:

- Double-click the arc to edit the Circular or ramping

motion:

In Numeric Mode, type:

- The Angular sector, Angular Orientation, Radius, and Ramping

angle for the Circular or ramping motion

- Angular sector

- By default, Angular Orientation

You can tilt the plane of circular

motion in Approach macro, Retract

macro, linking Approach, linking

Retract, and Between passes. This

provides better control of the tool motion to ensure longer lifecycle for the

tool and smoother surface quality. The Angular

Orientation parameter corresponds to the tilt angle and the tilted

arc is represented with GOTO points in the NC output. Since the motion is not in the plane

perpendicular to the tool axis, the circular interpolation (G41/G42) cannot be

generated. By default, By default,Angular

Orientation is set to 0. The plane is perpendicular to the tool

axis. Allowed values are between 0 and 90 degrees. Note:

Angular

Orientation exist for circular or ramping

macro mode only for ZLevel and Advanced

Finishing

Machining Operations.

- The Length and Angle for the

Prolonged motion and

- The Axial motion Distance.

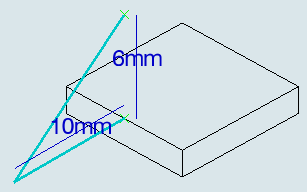

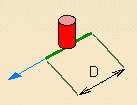

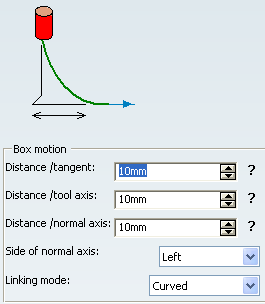

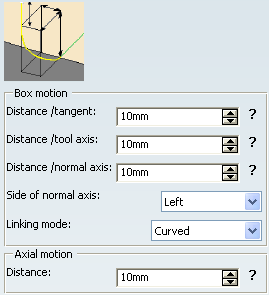

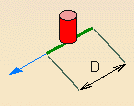

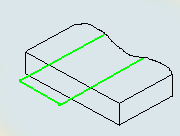

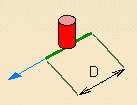

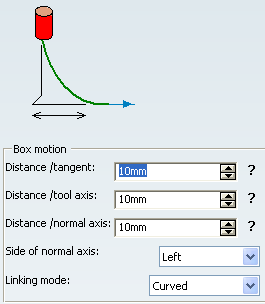

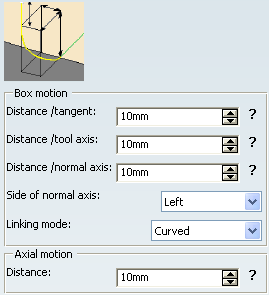

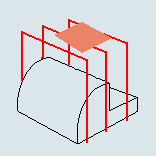

Box The tool moves across the diagonal of an imaginary box (Box motion), either

in a straight line or in a curve (Linking

mode).

The Box motion is defined by:

- The Distance along

the tangent,

- The Distance

along the tool axis (is a negative value),

- The Distance

along the normal axis,

- The direction of the box diagonal that is defined by whether

you want to use the normal to the left or the right of the end of

the tool path (Side of normal

axis). Left or Right is determined

by looking along the tool path in the direction of the

approach/retract.

- The Linking mode (Curved or

Straight).

The Axial motion Distance is the distance that the

tool moves in once it has crossed the box.

- Distance along the tangent,

- Distance along the tool axis,

- Distance along the normal axis.

In Graphic Mode:

- Double-click the magenta line to edit the Axial motion

Distance:

- Double-click the arc (yellow line) to edit the Box

motion:

In Numeric Mode:

- Type the values of the Distance/tangent,

Distance/tool axis, Distance/normal axis, and

of the Axial motion Distance.

- Choose from the list which side of the normal axis to determine the direction of the diagonal of the box.

- Select a Linking mode (Curved or

Straight).

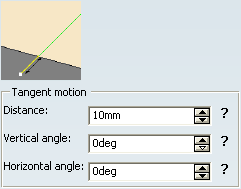

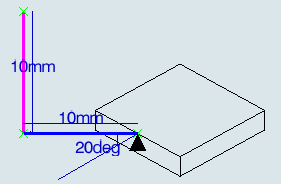

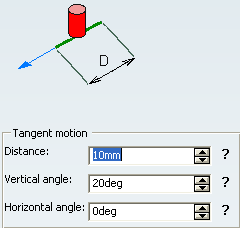

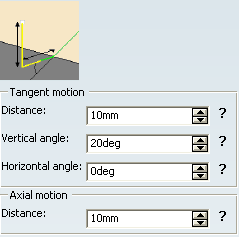

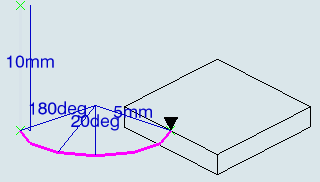

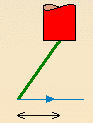

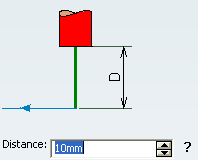

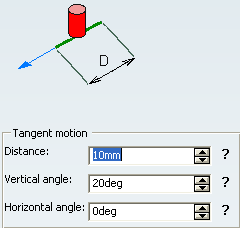

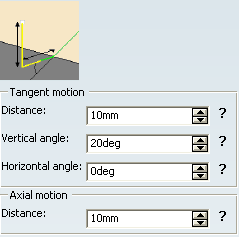

Prolonged Movement The tool moves in a straight line that may slant upwards.

The Prolonged motion is defined by:

- The Distance,

- The Vertical angle,

- The Horizontal angle,

The Axial motion is defined by the

Distance.

The advantage of this mode is that collisions are automatically detected. In the event that a

possible collision is detected, the angle is adjusted to avoid collision. If the angle

cannot be adjusted (because of the shape of the part, for example ), the length of the

prolongation is automatically adjusted to avoid collision.

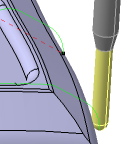

In Graphic Mode:

- Double-click the magenta line to edit the Axial motion

Distance:

- Double-click the yellow line to edit the Tangent

motion:

In Numeric Mode, type the Distance, the Vertical angle,

the Horizontal angle, and the Axial

motionDistance.

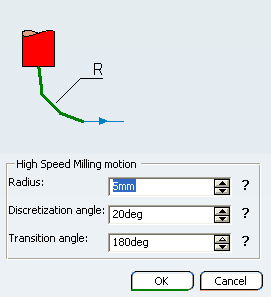

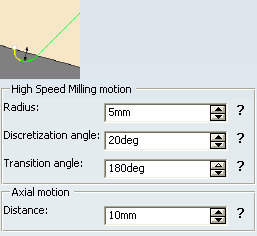

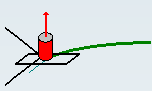

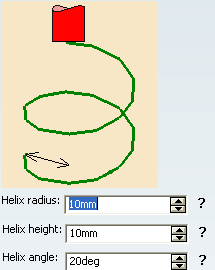

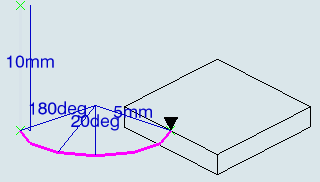

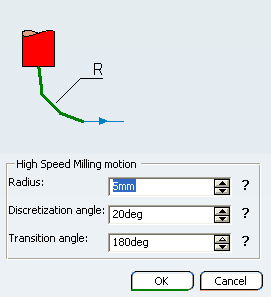

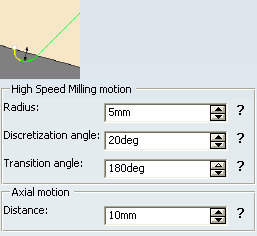

High-Speed Milling

The parameters are:

- Axial motion Distance,

- Transition radius which is the radius of the arc

that goes to the pass.

- Discretization angle which is a

value that, when reduced, gives a smoother tool path.

- Transition angle which is an

angle of the arc that goes to the pass.

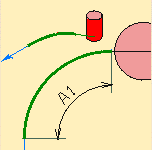

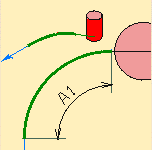

In Graphic Mode:

- Double-click the magenta line to edit the Axial motion

Distance:

- By default, double-click the green arc to edit the High Speed Milling

motion.

By default, the angle value is 180 degrees .

The Transition angle value lies between 0 and 180 degrees .

The old Machining Operations containing HSM macro is not changed if the default value is

kept.

In Numeric Mode, type the Radius,

Discretization angle, and the Transition angle defining the High Speed

Milling motion, and the Axial motion Distance.

Defined by Approach/Retract, Defined by Approach The macro used for the Linking Retract, Linking Approach or Between passes Link is that used for the Approach or the Retract. Build by user Available in Graphic Mode only.

Add several predefined

macros to create a machining path.

The current one is colored magenta.

If required, double-click:

- The line representing the macro to edit its parameter,

- The associated geometry representation to edit this geometry.

We have listed below:

- The icons,

- The name of the macros,

- The representation of the macros,

- The corresponding edition dialog box.

A context menu is

available: - Deactivate

- Deactivates the selected

macro path.

- You can deactivate macros by double-clicking an item in the list under .

- Activate

- Activates a path that was

previously deactivated.

- You can activate macros by double-clicking an item in the list under .

- Feedrate

- Allows you to modify the feedrate enter associated to the selected macro path by making a

selection in the sub-menu. If Local is selected, you can

assign a local feedrate value.

- Parameter

- Starts a dialog box to tune up the macro parameters.

Note:

The parameters dialog box can also be

launched by double-clicking a portion of the path in the viewer.

- Delete

- Deletes the current macro path.

- Insert

- Inserts another macro path.

The following macros are available:

Straight The tool goes directly to the next path.

ClearanceFor all clearances, if no safety plane is defined, the safety plane

is the upper point of the part.

- Optimized

- This means that if no

obstacle is detected between two passes, then the tool does not rise to the safety

plane. This is because it is not required and the Machining Operation takes less time. In some cases, where areas of the part are higher than the zone

you are machining and when you are using a safety plane, the tool cuts into the part.

When this happens, choose another clearance mode.

In both modes, you can only edit

the Distance parameter by double-clicking the label.

- Clearance Along Tool Axis

- The tool moves up to the defined safety plane along the tool

axis.

- Perpendicular to Safety Plane

- The tool moves up to the defined safety plane along an axis

perpendicular to the safety plane.

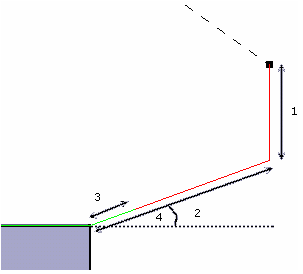

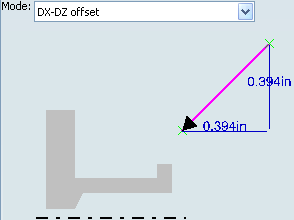

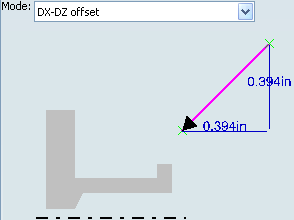

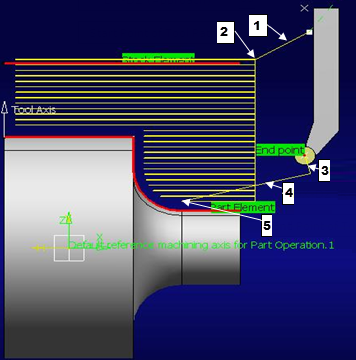

Mode DX-DZ Offset This provides support for the Macro definition within a programming Application for the Lathe

product to define the Macro Approach and Retract point

during Machining operation definition. You can do so by applying

DX and DZ offset values on start point and end point of toolpath. The DX and DZ values are applied on the start point and end point of toolpath to define Approach Macro and Retract Macro respectively.

Double-click the measurement, the Edit Parameter dialog box appears. Like other go-to-a-point macros, this macro is combined with other build-by-user macros, where the first macro is the DX-DZ offset. In the picture below, approach macro is of type DX-Dz Offset and retract is combination of DX-DZ offset and a build-by-user(motion to a point).

- DX-DZ approach

- Start point of tool path

- Build by user macro.

- DX-DZ retract

- End point of tool path

Options

This tab proposes clearance options.

Cornerized

clearance with radius

creates a cornerized clearance and enter the

value of the corner radius.

Smooth tool axis moves if the approach

and the retract axes are different, adds points on the rapid motion to smooth the transition

path. The tool axis is interpolated, according to the Max discretization

angle.

See Defining Macros |