Tool Parameters

Terminology for tool parameters has evolved. The illustrations in this document

are not up to date. Please use the following table as a reference.

| Old Parameter |

ISO Parameter |

Attribute |

| Cutting angle 2 (A2) |

Step included angle (STA_3) |

MFG_ANGLE2 |

| Body diameter (db) |

Shank diameter (DMM) |

MFG_BODY_DIAM |

| Chamfer diameter 1 (d1) |

Cutting diameter 2 (DC_2) |

MFG_CHAMFR_DIAM1 |

| Chamfer diameter 2 (d2) |

Cutting diameter 3 (DC_3) |

MFG_CHAMFR_DIAM2 |

| Corner radius (Rc) |

Corner radius (RE) |

MFG_CORNER_RAD |

| Upper Corner radius (Rc2) |

Upper corner radius (RE2) |

MFG_CORNER_RAD_2 |

| Cutting angle (A) |

Tool cutting edge angle (KAPR) |

MFG_CUT_ANGLE |

| Cutting length (Lc) |

Depth of cut maximum (APMX) |

MFG_CUT_LENGTH |

| Entry diameter (d) |

Entry diameter (DE) |

MFG_ENTRY_DIAM |

| Length (l) |

Head length (LH) |

MFG_LENGTH |

| Length 1 (l1) |

Step diameter length (SDL_2) |

MFG_LENGTH_1 |

| Length 2 (l2) |

Step diameter length (SDL_3) |

MFG_LENGTH_2 |

| Bottom chamfer angle (A1) |

Bottom tool cutting edge angle (KAPR1) |

MFG_LOWER_ANGLE |

| Bottom diameter (D1) |

Bottom cutting diameter (DC1) |

MFG_LOWER_DIAM |

| Nominal diameter (D) |

Cutting diameter (DC) |

MFG_NOMINAL_DIAM |

| Outside diameter (Da) |

Cutting diameter max (DCX) |

MFG_OUTSIDE_DIAM |

| Overall length (L) |

Overall length (OAL) |

MFG_OVERALL_LGTH |

| Taper angle (Ach) |

Taper angle (STA_2) |

MFG_TAPER_ANGLE |

| Tool tip length (ld) |

Point length (PL) |

MFG_TL_TIP_LGTH |

| Top chamfer angle (A2) |

Top tool cutting edge angle (KAPR2) |

MFG_UPPER_ANGLE |

| Top diameter (D2) |

Top cutting diameter (DC2) |

MFG_UPPER_DIAM |

| Non cut diameter (dn) |

(unchanged) |

MFG_NON_CUT_DIAM |

| Tip angle (E) |

(unchanged) |

MFG_TIP_ANGLE |

| Tip radius (Re) |

(unchanged) |

MFG_TIP_RADIUS |

| Tip length (lt) |

(unchanged) |

MFG_TIP_LENGTH |

| Tool angle (B) |

(unchanged) |

MFG_TOOL_ANGLE |

| Radial distance (Xce) |

(unchanged) |

MFG_RADIAL_DISTANCE |

| Vertical distance (Zce) |

(unchanged) |

MFG_VERTICAL_DISTANCE |

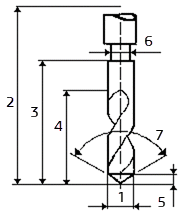

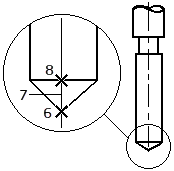

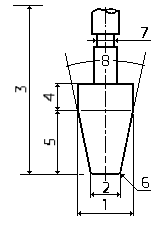

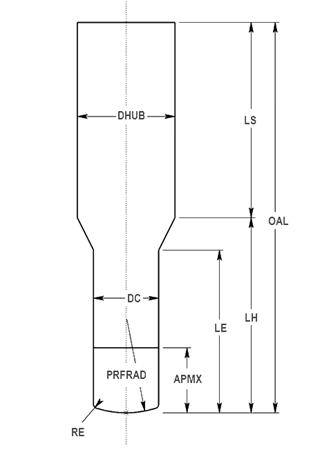

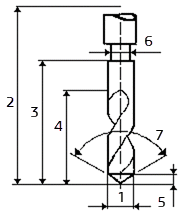

Drill

The MFG_NAME_BAS attribute for this tool is MfgDrillTool.

This tool type has three compensation sites P1 to P3 (8-10), which are located

on the tool as shown below.

Manufacturing geometry attributes used in this resource are:

| Number on Image |

Description |

Parameter |

Attribute |

| 1 |

Cutting Diameter |

DC |

MFG_NOMINAL_DIAM |

| 2 |

Overall Length |

OAL |

MFG_OVERALL_LGTH |

| 3 |

Head Length |

LH |

MFG_LENGTH |

| 4 |

Depth of Cut Maximum |

APMX |

MFG_CUT_LENGTH |

| 5 |

Point Length |

PL |

MFG_TL_TIP_LGTH |

| 6 |

Hub Diameter |

DHUB |

MFG_BODY_DIAM |

| 7 |

Tool Cutting Edge |

KAPR |

MFG_CUT_ANGLE |

MfgDrillTool resource attributes are described below.

Base Attributes

These attributes provide general information.

- MFG_NAME (Name)

-

Type:

String

Associates a name to the resource.

- MFG_COMMENT (Comment)

-

Type:

String

Associates a comment to the resource.

- MFG_TOOL_NUMBER (Tool number)

-

Type: Integer

Defines the tool number.

Geometry Attributes

These attributes characterize the tool shape and have an impact on the tool path

computation.

- MFG_NOMINAL_DIAM (Cutting diameter: DC)

-

Type:

Real

Defines the cutting diameter of the tool.

- MFG_OVERALL_LGTH (Overall length: OAL)

-

Type:

Real

Defines the total length of the tool.

- MFG_CUT_LENGTH (Depth of cut maximum: APMX)

-

Type:

Real

Defines the effective cutting length available on the active part of the tool.

- MFG_LENGTH (Head length: LH)

-

Type:

Real

Defines the length of the external envelope of the active part of the tool.

- MFG_BODY_DIAM (Hub diameter: DHUB)

-

Type:

Real

Defines the diameter of the external envelope of the non-active part of

the tool.

- MFG_CUT_ANGLE (Tool cutting edge: KAPR)

-

Type:

Real

Defines the cutting angle of the tool.

- MFG_TL_TIP_LGTH (Point length: PL)

-

Type:

Real

Defines the part of the tool that cannot be used for cutting material at

the correct diameter (non-functional part of the tool).

Technology Attributes

These attributes provide technological information without any impact on the tool

path computation.

- MFG_NB_OF_FLUTES (Number of flutes)

-

Type: Integer

Defines the number of flutes on the tool. In case of tools with separate

inserts, this is the number of inserts.

- MFG_WAY_OF_ROT (Way of rotation)

-

Type:

String

Possible values:

- RIGHT_HAND (Right hand)

- LEFT_HAND (Left hand)

Defines the rotation orientation of the current element. It should be compatible with spindle rotation

orientation.

- MFG_MACH_QUALITY (Machining quality)

-

Type:

String

Possible values:

- ROUGH (Rough)

- FINISH (Finish)

- EITHER (Either)

Defines the tool ability to machine in roughing or finishing mode.

- MFG_TOOTH_MAT (Tooth material)

-

Type:

String

Possible values:

- HIGH_SPEED_STEEL (High speed steel)

- COATED_HIGH_SPEED_STEEL (Coated high speed steel)

- CARBIDE (Carbide)

- COATED_CARBIDE (Coated carbide)

- OTHER (Other)

Defines the tooth material type.

- MFG_TOOTH_DES (Tooth description)

-

Type:

String

Allows to specify the tooth nature as a comment. For example, it

could be the supplier reference of the insert.

- MFG_TOOTH_MATDES (Tooth material desc.)

-

Type:

String

Allows to specify the tooth material by means of a comment. For

example, it could be the ISO designation for cutting materials or the reference

of the coating material.

- MFG_TL_RAKE_ANG (Tool rake angle)

-

Type:

Real

Defines the tool rake angle.

- MFG_MAX_MIL_LENGTH (Max machining length)

-

Type:

Real

Specifies the tool life in length units.

- MFG_MAX_MIL_TIME (Max life time)

-

Type:

Real

Specifies the tool life in time units.

- MFG_COOLNT_SNTX (Coolant syntax)

-

Type:

String

Specifies the coolant supply syntax.

- MFG_WEIGHT_SNTX (Weight syntax)

-

Type:

String

Specifies the tool weight syntax.

- MFG_MAX_CHIP_THICKNESS (Max Chip thickness)

Specifies a maximum thickness value for the chips to be removed

during machining. - MFG_MAX_VOL_RATE (Max Volume rate)

Specifies a maximum volume value for the chips to be removed during

machining. - MFG_MAX_POWER (Max Power)

Specifies a maximum power value required for the material to be

removed during machining.

Cutting Conditions Attributes

These attributes are used for feeds and speeds computation on the operation.

- MFG_VC (Cutting speed)

-

Type:

Real

Defines the Cutting speed of the tool.

- MFG_SZ (Feedrate)

-

Type:

Real

Defines the Feedrate of the tool.

- MFG_PP (Depth of cut)

-

Type:

Real

Defines the Depth of cut of the tool.

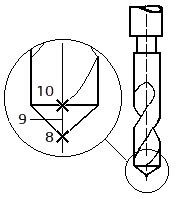

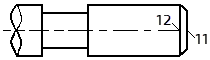

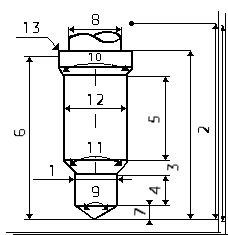

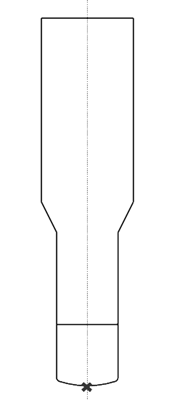

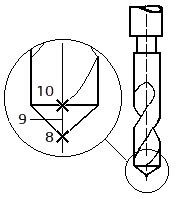

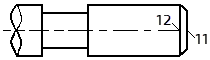

Tap

The MFG_NAME_BAS attribute for this tool is MfgTapTool.

This tool type has three compensation sites:

- P1 (8) is located at the extremity of the tool

- P2 (9) is defined by a diameter value (dP2)

- P3 (10) is located along the tool axis at a distance from P1

defined as follows: P1P2 = ld * (dP2-d)/(D-d).

Manufacturing geometry attributes used in this resource are:

| Number on Image |

Description |

Parameter |

Attribute |

| 1 |

Cutting Diameter |

DC |

MFG_NOMINAL_DIAM |

| 2 |

Overall Length |

OAL |

MFG_OVERALL_LGTH |

| 3 |

Head Length |

LH |

MFG_LENGTH |

| 4 |

Depth of Cut Maximum |

APMX |

MFG_CUT_LENGTH |

| 5 |

Point Length |

PL |

MFG_TL_TIP_LGTH |

| 6 |

Shank Diameter |

DMM |

MFG_BODY_DIAM |

| 7 |

Entry Diameter |

DE |

MFG_ENTRY_DIAM |

MfgTapTool resource attributes are described below.

Base Attributes

These attributes provide general information.

- MFG_NAME (Name)

-

Type:

String

Associates a name to the resource.

- MFG_COMMENT (Comment)

-

Type:

String

Associates a comment to the resource.

- MFG_TOOL_NUMBER (Tool number)

-

Type: Integer

Defines the tool number.

Geometry Attributes

These attributes characterize the tool shape and have an impact on the tool path

computation.

- MFG_NOMINAL_DIAM (Cutting diameter: DC)

-

Type:

Real

Defines the cutting diameter of the tool.

- MFG_OVERALL_LGTH (Overall length: OAL)

-

Type:

Real

Defines the total length of the tool.

- MFG_CUT_LENGTH (Depth of cut maximum: APMX)

-

Type:

Real

Defines the effective cutting length available on the active part of the tool.

- MFG_LENGTH (Head length: LH)

-

Type:

Real

Defines the length of the external envelope of the active part of the tool.

- MFG_BODY_DIAM (Shank diameter: DMM)

-

Type:

Real

Defines the diameter of the external envelope of the non-active part of

the tool.

- MFG_ENTRY_DIAM (Entry diameter: DE)

-

Type:

Real

Defines the smallest diameter of the head of the tool.

- MFG_TL_TIP_LGTH (Point length: PL)

-

Type:

Real

Defines the part of the tool that cannot be used for cutting material at

the correct diameter (non-functional part of the tool).

Technology Attributes

These attributes provide technological information without any impact on the tool

path computation.

- MFG_NB_OF_FLUTES (Number of flutes)

-

Type: Integer

Defines the number of flutes on the tool. In case of tools with separate

inserts, this is the number of inserts.

- MFG_WAY_OF_ROT (Way of rotation)

-

Type:

String

Possible values:

- RIGHT_HAND (Right hand)

- LEFT_HAND (Left hand)

Defines the rotation orientation of the current element. It should be compatible with spindle rotation

orientation.

- MFG_TOOTH_MAT (Tooth material)

-

Type:

String

Possible values:

- HIGH_SPEED_STEEL (High speed steel)

- COATED_HIGH_SPEED_STEEL (Coated high speed steel)

- CARBIDE (Carbide)

- COATED_CARBIDE (Coated carbide)

- OTHER (Other)

Defines the tooth material type.

- MFG_TOOTH_DES (Tooth description)

-

Type:

String

Allows to specify the tooth nature as a comment. For example, it

could be the supplier reference of the insert.

- MFG_TOOTH_MATDES (Tooth material desc.)

-

Type:

String

Allows to specify the tooth material by means of a comment. For

example, it could be the ISO designation for cutting materials or the reference

of the coating material.

- MFG_THREAD_FORM (Thread form)

-

Type:

String

Possible values:

- METRIC (Metric)

- INCH (Inch)

- OTHER (Other)

Defines the standard of the thread used on a tap.

- MFG_THREAD_CLASS (Thread class)

-

Type:

String

Defines the dimensional tolerances of the thread and can take the following

values: - 1B (consistent with INCH thread form),

- 2B (consistent with INCH

thread form),

- 3B (consistent with INCH thread form),

- 5H (consistent with

METRIC thread form),

- 6H (consistent with METRIC thread form),

- 7H (consistent

with METRIC thread form),

- OTHER.

- MFG_THD_FRM_DESC (Thread form desc.)

-

Type:

String

Specifies the thread form as a comment. For example, it could be some other

thread form like Round thread.

- MFG_THD_CLS_DESC (Thread class desc.)

-

Type:

String

Specifies the thread class as a comment.

- MFG_PITCH_OF_THREAD (Pitch of thread)

-

Type:

Real

Describes the thread pitch.

- MFG_MAX_MIL_LENGTH (Max machining length)

-

Type:

Real

Specifies the tool life in length units.

- MFG_MAX_MIL_TIME (Max life time)

-

Type:

Real

Specifies the tool life in time units.

- MFG_COOLNT_SNTX (Coolant syntax)

-

Type:

String

Specifies the coolant supply syntax.

- MFG_WEIGHT_SNTX (Weight syntax)

-

Type:

String

Specifies the tool weight syntax.

- MFG_MAX_CHIP_THICKNESS (Max Chip thickness)

Specifies a maximum thickness value for the chips to be removed

during machining. - MFG_MAX_VOL_RATE (Max Volume rate)

Specifies a maximum volume value for the chips to be removed during

machining. - MFG_MAX_POWER (Max Power)

Specifies a maximum power value required for the material to be

removed during machining.

Cutting Conditions Attributes

These attributes are used for feeds and speeds computation on the operation.

- MFG_VC (Cutting speed)

-

Type:

Real

Defines the Cutting speed of the tool.

- MFG_SZ (Feedrate)

-

Type:

Real

Defines the Feedrate of the tool.

- MFG_PP (Depth of cut)

-

Type:

Real

Defines the Depth of cut of the tool.

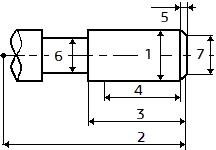

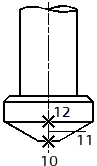

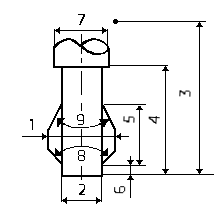

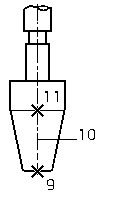

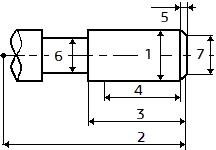

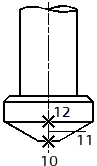

Thread Mill

The MFG_NAME_BAS attribute for this tool is MfgThreadMillTool

This tool type has two compensation sites:

- P1 (11) is located at the extremity of the tool.

- P2 (12) is located along the tool axis at a distance from P1 defined as

follows: P1P2 = (D-d)/(2*tg Ac)

Manufacturing geometry attributes used in this resource are:

| Number on Image |

Description |

Parameter |

Attribute |

| 1 |

Cutting Diameter |

DC |

MFG_NOMINAL_DIAM |

| 2 |

Overall Length |

OAL |

MFG_OVERALL_LGTH |

| 3 |

Head Length |

LH |

MFG_LENGTH |

| 4 |

Depth of Cut Maximum |

APMX |

MFG_CUT_LENGTH |

| 5 |

Cutting Diameter Max |

DCX |

MFG_OUTSIDE_DIAM |

| 6 |

Shank Diameter |

DMM |

MFG_BODY_DIAM |

| 7 |

Entry Diameter |

DE |

MFG_ENTRY_DIAM |

| 8 |

Step Diameter Length |

SDL_2 |

MFG_LENGTH_1 |

| 9 |

Taper Angle |

STA_2 |

MFG_TAPER_ANGLE |

| 10 |

Tool Cutting Edge Angle |

KAPR |

MFG_CHAMFER_ ANGLE

|

MfgThreadMillTool resource attributes are described below.

Base Attributes

These attributes provide general information.

- MFG_NAME (Name)

-

Type:

String

Associates a name to the resource.

- MFG_COMMENT (Comment)

-

Type:

String

Associates a comment to the resource.

- MFG_TOOL_NUMBER (Tool number)

-

Type: Integer

Defines the tool number.

Geometry Attributes

These attributes characterize the tool shape and have an impact on the tool path

computation.

- MFG_NOMINAL_DIAM (Cutting diameter: DC)

-

Type:

Real

Defines the cutting diameter of the tool.

- MFG_OVERALL_LGTH (Overall length: OAL)

-

Type:

Real

Defines the total length of the tool.

- MFG_CUT_LENGTH (Depth of cut maximum: APMX)

-

Type:

Real

Defines the effective cutting length available on the active part of the tool.

- MFG_LENGTH (Head length: LH)

-

Type:

Real

Defines the length of the external envelope of the active part of the tool.

- MFG_BODY_DIAM (Shank diameter: DMM)

-

Type:

Real

Defines the diameter of the external envelope of the non-active part of

the tool.

- MFG_OUTSIDE_DIAM (Cutting diameter max: DCX)

-

Type:

Real

Defines the diameter of the external envelope of the tool active part

for tools such as face mills, countersinks and thread mills.

- MFG_LENGTH_1 (Step diameter length: SDL_2)

-

Type:

Real

Defines the length of the first active part for tools such as multi-diameter

tool, bore-and-chamfer tool, and thread mill.

- MFG_TAPER_ANGLE (Taper angle: TA)

-

Type:

Real

Defines the taper angle on the tool.

- MFG_CHAMFER_ANGLE (Tool cutting edge angle: KAPR)

-

Type:

Real

Defines the chamfer angle of the tool.

Technology Attributes

These attributes provide technological information without any impact on the tool

path computation.

- MFG_NB_OF_FLUTES (Number of flutes)

-

Type: Integer

Defines the number of flutes on the tool. In case of tools with separate

inserts, this is the number of inserts.

- MFG_WAY_OF_ROT (Way of rotation)

-

Type:

String

Possible values:

- RIGHT_HAND (Right hand)

- LEFT_HAND (Left hand)

Defines the rotation orientation of the current element. It should be compatible with spindle rotation

orientation.

- MFG_TOOTH_MAT (Tooth material)

-

Type:

String

Possible values:

- HIGH_SPEED_STEEL (High speed steel)

- COATED_HIGH_SPEED_STEEL (Coated high speed steel)

- CARBIDE (Carbide)

- COATED_CARBIDE (Coated carbide)

- OTHER (Other)

Defines the tooth material type.

- MFG_TOOTH_DES (Tooth description)

-

Type:

String

Allows to specify the tooth nature as a comment. For example, it

could be the supplier reference of the insert.

- MFG_TOOTH_MATDES (Tooth material desc.)

-

Type:

String

Allows to specify the tooth material by means of a comment. For

example, it could be the ISO designation for cutting materials or the reference

of the coating material.

- MFG_THREAD_FORM (Thread form)

-

Type:

String

Possible values:

- METRIC (Metric)

- INCH (Inch)

- OTHER (Other)

Defines the standard of the thread used on a tap.

- MFG_THREAD_CLASS (Thread class)

-

Type:

String

Defines the dimensional tolerances of the thread and can take the following

values: - 1B (consistent with INCH thread form),

- 2B (consistent with INCH

thread form),

- 3B (consistent with INCH thread form),

- 5H (consistent with

METRIC thread form),

- 6H (consistent with METRIC thread form),

- 7H (consistent

with METRIC thread form),

- OTHER.

- MFG_THD_FRM_DESC (Thread form desc.)

-

Type:

String

Specifies the thread form as a comment. For example, it could be some other

thread form like Round thread.

- MFG_THD_CLS_DESC (Thread class desc.)

-

Type:

String

Specifies the thread class as a comment.

- MFG_PITCH_OF_THREAD (Pitch of thread)

-

Type:

Real

Describes the thread pitch.

- MFG_MAX_MIL_LENGTH (Max machining length)

-

Type:

Real

Specifies the tool life in length units.

- MFG_MAX_MIL_TIME (Max life time)

-

Type:

Real

Specifies the tool life in time units.

- MFG_COOLNT_SNTX (Coolant syntax)

-

Type:

String

Specifies the coolant supply syntax.

- MFG_WEIGHT_SNTX (Weight syntax)

-

Type:

String

Specifies the tool weight syntax.

- MFG_MAX_CHIP_THICKNESS (Max Chip thickness)

Specifies a maximum thickness value for the chips to be removed

during machining. - MFG_MAX_VOL_RATE (Max Volume rate)

Specifies a maximum volume value for the chips to be removed during

machining. - MFG_MAX_POWER (Max Power)

Specifies a maximum power value required for the material to be

removed during machining.

Cutting Conditions Attributes

These attributes are used for feeds and speeds computation on the operation.

- MFG_VC (Cutting speed)

-

Type:

Real

Defines the Cutting speed of the tool.

- MFG_SZ (Feedrate)

-

Type:

Real

Defines the Feedrate of the tool.

- MFG_PP (Depth of cut)

-

Type:

Real

Defines the Depth of cut of the tool.

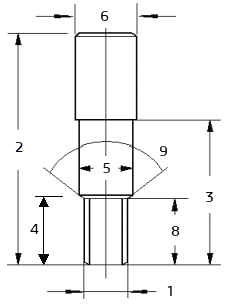

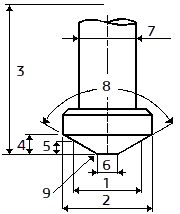

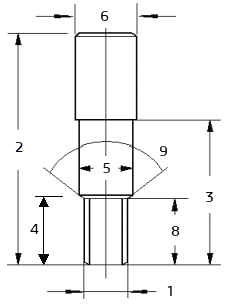

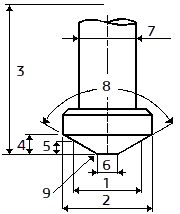

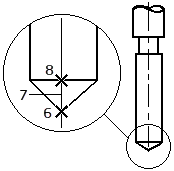

Countersink

The MFG_NAME_BAS attribute for this tool is MfgCountersinkTool.

This tool type has three compensation sites P1 to P3, (10-12) which are located

on the tool as shown below.

Manufacturing geometry attributes used in this resource are:

| Number on Image |

Description |

Parameter |

Attribute |

| 1 |

Cutting Diameter |

DC |

MFG_NOMINAL_DIAM |

| 2 |

Cutting Diameter Max |

DCX |

MFG_OUTSIDE_DIAM |

| 3 |

Overall Length |

OAL |

MFG_OVERALL_LGTH |

| 4 |

Head Length |

LH |

MFG_LENGTH |

| 5 |

Depth of Cut Maximum |

APMX |

MFG_CUT_LENGTH |

| 6 |

Entry Diameter |

DE |

MFG_ENTRY_DIAM |

| 7 |

Hub Diameter |

DHUB |

MFG_BODY_DIAM |

| 8 |

Tool Cutting Edge Angle |

KAPR |

MFG_CUT_ANGLE |

| 9 |

Corner radius |

RE |

MFG_CORNER_RAD |

MfgCountersinkTool resource attributes are described below.

Base Attributes

These attributes provide general information.

- MFG_NAME (Name)

-

Type:

String

Associates a name to the resource.

- MFG_COMMENT (Comment)

-

Type:

String

Associates a comment to the resource.

- MFG_TOOL_NUMBER (Tool number)

-

Type: Integer

Defines the tool number.

Geometry Attributes

These attributes characterize the tool shape and have an impact on the tool path

computation.

- MFG_NOMINAL_DIAM (Cutting diameter: DC)

-

Type:

Real

Defines the cutting diameter of the tool.

- MFG_CORNER_RAD (Corner radius: RE)

-

Type:

Real

Defines the radius of the cutting shape of the tool.

- MFG_OVERALL_LGTH (Overall length: OAL)

-

Type:

Real

Defines the total length of the tool.

- MFG_CUT_LENGTH (Depth of cut maximum: APMX)

-

Type:

Real

Defines the effective cutting length available on the active part of the tool.

- MFG_LENGTH (Head length: LH)

-

Type:

Real

Defines the length of the external envelope of the active part of the tool.

- MFG_BODY_DIAM (Shank diameter: DMM)

-

Type:

Real

Defines the diameter of the external envelope of the non-active part of

the tool.

- MFG_ENTRY_DIAM (Entry diameter: DE)

-

Type:

Real

Defines the smallest diameter of the head of the tool.

- MFG_OUTSIDE_DIAM (Cutting diameter max: DCX)

-

Type:

Real

Defines the diameter of the external envelope of the tool active part

for tools such as face mills, countersinks and thread mills.

- MFG_CUT_ANGLE (Tool cutting edge angle: KAPR)

-

Type:

Real

Defines the cutting angle of the tool.

Technology Attributes

These attributes provide technological information without any impact on the tool

path computation.

- MFG_NB_OF_FLUTES (Number of flutes)

-

Type: Integer

Defines the number of flutes on the tool. In case of tools with separate

inserts, this is the number of inserts.

- MFG_WAY_OF_ROT (Way of rotation)

-

Type:

String

Possible values:

- RIGHT_HAND (Right hand)

- LEFT_HAND (Left hand)

Defines the rotation orientation of the current element. It should be compatible with spindle rotation

orientation.

- MFG_MACH_QUALITY (Machining quality)

-

Type:

String

Possible values:

- ROUGH (Rough)

- FINISH (Finish)

- EITHER (Either)

Defines the tool ability to machine in roughing or finishing mode.

- MFG_TOOTH_MAT (Tooth material)

-

Type:

String

Possible values:

- HIGH_SPEED_STEEL (High speed steel)

- COATED_HIGH_SPEED_STEEL (Coated high speed steel)

- CARBIDE (Carbide)

- COATED_CARBIDE (Coated carbide)

- OTHER (Other)

Defines the tooth material type.

- MFG_TOOTH_DES (Tooth description)

-

Type:

String

Allows to specify the tooth nature as a comment. For example, it

could be the supplier reference of the insert.

- MFG_TOOTH_MATDES (Tooth material desc.)

-

Type:

String

Allows to specify the tooth material by means of a comment. For

example, it could be the ISO designation for cutting materials or the reference

of the coating material.

- MFG_TL_RAKE_ANG (Tool rake angle)

-

Type:

Real

Defines the tool rake angle.

- MFG_MAX_MIL_LENGTH (Max machining length)

-

Type:

Real

Specifies the tool life in length units.

- MFG_MAX_MIL_TIME (Max life time)

-

Type:

Real

Specifies the tool life in time units.

- MFG_COOLNT_SNTX (Coolant syntax)

-

Type:

String

Specifies the coolant supply syntax.

- MFG_WEIGHT_SNTX (Weight syntax)

-

Type:

String

Specifies the tool weight syntax.

- MFG_MAX_CHIP_THICKNESS (Max Chip thickness)

Specifies a maximum thickness value for the chips to be removed

during machining. - MFG_MAX_VOL_RATE (Max Volume rate)

Specifies a maximum volume value for the chips to be removed during

machining. - MFG_MAX_POWER (Max Power)

Specifies a maximum power value required for the material to be

removed during machining.

Cutting Conditions Attributes

These attributes are used for feeds and speeds computation on the operation.

- MFG_VC (Cutting speed)

-

Type:

Real

Defines the Cutting speed of the tool.

- MFG_SZ (Feedrate)

-

Type:

Real

Defines the Feedrate of the tool.

- MFG_PP (Depth of cut)

-

Type:

Real

Defines the Depth of cut of the tool.

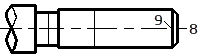

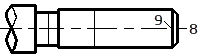

Reamer

The MFG_NAME_BAS attribute for this tool is MfgReamerTool.

This tool type has two compensation sites:

- P1 (8) is located at the extremity of the tool.

- P2 (9) is located a distance ld from P1 along the tool axis.

Manufacturing geometry attributes used in this resource are:

| Number on Image |

Description |

Parameter |

Attribute |

| 1 |

Cutting Diameter |

DC |

MFG_NOMINAL_DIAM |

| 2 |

Overall Length |

OAL |

MFG_OVERALL_LGTH |

| 3 |

Head Length |

LH |

MFG_LENGTH |

| 4 |

Depth of cut maximum |

APMX |

MFG_CUT_LENGTH |

| 5 |

Point Length |

PL |

MFG_TL_TIP_LGTH |

| 6 |

Entry Diameter |

DE |

MFG_ENTRY_DIAM |

| 7 |

Shank Diameter |

DMM |

MFG_BODY_DIAM |

MfgReamerTool resource attributes are described below.

Base Attributes

These attributes provide general information.

- MFG_NAME (Name)

-

Type:

String

Associates a name to the resource.

- MFG_COMMENT (Comment)

-

Type:

String

Associates a comment to the resource.

- MFG_TOOL_NUMBER (Tool number)

-

Type: Integer

Defines the tool number.

Geometry Attributes

These attributes characterize the tool shape and have an impact on the tool path

computation.

- MFG_NOMINAL_DIAM (Cutting diameter: DC)

-

Type:

Real

Defines the cutting diameter of the tool.

- MFG_OVERALL_LGTH (Overall length: OAL)

-

Type:

Real

Defines the total length of the tool.

- MFG_CUT_LENGTH (Depth of cut maximum: APMX)

-

Type:

Real

Defines the effective cutting length available on the active part of the tool.

- MFG_LENGTH (Head Length: HL)

-

Type:

Real

Defines the length of the external envelope of the active part of the tool.

- MFG_BODY_DIAM (Shank diameter: DMM)

-

Type:

Real

Defines the diameter of the external envelope of the non-active part of

the tool.

- MFG_ENTRY_DIAM (Entry diameter: DE)

-

Type:

Real

Defines the smallest diameter of the head of the tool.

- MFG_TL_TIP_LGTH (Point length: PL)

-

Type:

Real

Defines the part of the tool that cannot be used for cutting material at

the correct diameter (non-functional part of the tool).

Technology Attributes

These attributes provide technological information without any impact on the tool

path computation.

- MFG_NB_OF_FLUTES (Number of flutes)

-

Type: Integer

Defines the number of flutes on the tool. In case of tools with separate

inserts, this is the number of inserts.

- MFG_WAY_OF_ROT (Way of rotation)

-

Type:

String

Possible values:

- RIGHT_HAND (Right hand)

- LEFT_HAND (Left hand)

Defines the rotation orientation of the current element. It should be compatible with spindle rotation

orientation.

- MFG_TOOTH_MAT (Tooth material)

-

Type:

String

Possible values:

- HIGH_SPEED_STEEL (High speed steel)

- COATED_HIGH_SPEED_STEEL (Coated high speed steel)

- CARBIDE (Carbide)

- COATED_CARBIDE (Coated carbide)

- OTHER (Other)

Defines the tooth material type.

- MFG_TOOTH_DES (Tooth description)

-

Type:

String

Allows to specify the tooth nature as a comment. For example, it

could be the supplier reference of the insert.

- MFG_TOOTH_MATDES (Tooth material desc.)

-

Type:

String

Allows to specify the tooth material by means of a comment. For

example, it could be the ISO designation for cutting materials or the reference

of the coating material.

- MFG_TL_RAKE_ANG (Tool rake angle)

-

Type:

Real

Defines the tool rake angle.

- MFG_MAX_MIL_LENGTH (Max machining length)

-

Type:

Real

Specifies the tool life in length units.

- MFG_MAX_MIL_TIME (Max life time)

-

Type:

Real

Specifies the tool life in time units.

- MFG_COOLNT_SNTX (Coolant syntax)

-

Type:

String

Specifies the coolant supply syntax.

- MFG_WEIGHT_SNTX (Weight syntax)

-

Type:

String

Specifies the tool weight syntax.

- MFG_MAX_CHIP_THICKNESS (Max Chip thickness)

Specifies a maximum thickness value for the chips to be removed

during machining. - MFG_MAX_VOL_RATE (Max Volume rate)

Specifies a maximum volume value for the chips to be removed during

machining. - MFG_MAX_POWER (Max Power)

Specifies a maximum power value required for the material to be

removed during machining.

Cutting Conditions Attributes

These attributes are used for feeds and speeds computation on the operation.

- MFG_VC (Cutting speed)

-

Type:

Real

Defines the Cutting speed of the tool.

- MFG_SZ (Feedrate)

-

Type:

Real

Defines the Feedrate of the tool.

- MFG_PP (Depth of cut)

-

Type:

Real

Defines the Depth of cut of the tool.

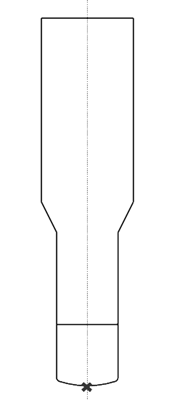

Spot Drill

The MFG_NAME_BAS attribute for this tool is MfgSpotDrillTool.

This tool type has three compensation sites P1 to P3 (6-8) which are located on

the tool as shown below.

Manufacturing geometry attributes used in this resource are:

| Number on Image |

Description |

Parameter |

Attribute |

| 1 |

Cutting Diameter |

DC |

MFG_NOMINAL_DIAM |

| 2 |

Overall Length |

OAL |

MFG_OVERALL_LGTH |

| 3 |

Head Length |

LH |

MFG_LENGTH |

| 4 |

Shank Diameter |

DMM |

MFG_BODY_DIAM |

| 5 |

Tool Cutting Edge Angle |

KAPR |

MFG_CUT_ANGLE |

MfgSpotDrillTool resource attributes are described below.

Base Attributes

These attributes provide general information.

- MFG_NAME (Name)

-

Type:

String

Associates a name to the resource.

- MFG_COMMENT (Comment)

-

Type:

String

Associates a comment to the resource.

- MFG_TOOL_NUMBER (Tool number)

-

Type: Integer

Defines the tool number.

Geometry Attributes

These attributes characterize the tool shape and have an impact on the tool path

computation.

- MFG_NOMINAL_DIAM (Cutting diameter: DC)

-

Type:

Real

Defines the cutting diameter of the tool.

- MFG_OVERALL_LGTH (Overall length: OAL)

-

Type:

Real

Defines the total length of the tool.

- MFG_LENGTH (Head Length: HL)

-

Type:

Real

Defines the length of the external envelope of the active part of the tool.

- MFG_BODY_DIAM (Shank diameter: DMM)

-

Type:

Real

Defines the diameter of the external envelope of the non-active part of

the tool.

- MFG_CUT_ANGLE (Tool cutting edge angle: KAPR)

-

Type:

Real

Defines the cutting angle of the tool.

Technology Attributes

These attributes provide technological information without any impact on the tool

path computation.

- MFG_NB_OF_FLUTES (Number of flutes)

-

Type: Integer

Defines the number of flutes on the tool. In case of tools with separate

inserts, this is the number of inserts.

- MFG_WAY_OF_ROT (Way of rotation)

-

Type:

String

Possible values:

- RIGHT_HAND (Right hand)

- LEFT_HAND (Left hand)

Defines the rotation orientation of the current element. It should be compatible with spindle rotation

orientation.

- MFG_TOOTH_MAT (Tooth material)

-

Type:

String

Possible values:

- HIGH_SPEED_STEEL (High speed steel)

- COATED_HIGH_SPEED_STEEL (Coated high speed steel)

- CARBIDE (Carbide)

- COATED_CARBIDE (Coated carbide)

- OTHER (Other)

Defines the tooth material type.

- MFG_TOOTH_DES (Tooth description)

-

Type:

String

Allows to specify the tooth nature as a comment. For example, it

could be the supplier reference of the insert.

- MFG_TOOTH_MATDES (Tooth material desc.)

-

Type:

String

Allows to specify the tooth material by means of a comment. For

example, it could be the ISO designation for cutting materials or the reference

of the coating material.

- MFG_TL_RAKE_ANG (Tool rake angle)

-

Type:

Real

Defines the tool rake angle.

- MFG_MAX_MIL_LENGTH (Max machining length)

-

Type:

Real

Specifies the tool life in length units.

- MFG_MAX_MIL_TIME (Max life time)

-

Type:

Real

Specifies the tool life in time units.

- MFG_COOLNT_SNTX (Coolant syntax)

-

Type:

String

Specifies the coolant supply syntax.

- MFG_WEIGHT_SNTX (Weight syntax)

-

Type:

String

Specifies the tool weight syntax.

- MFG_MAX_CHIP_THICKNESS (Max Chip thickness)

Specifies a maximum thickness value for the chips to be removed

during machining. - MFG_MAX_VOL_RATE (Max Volume rate)

Specifies a maximum volume value for the chips to be removed during

machining. - MFG_MAX_POWER (Max Power)

Specifies a maximum power value required for the material to be

removed during machining.

Cutting Conditions Attributes

These attributes are used for feeds and speeds computation on the operation.

- MFG_VC (Cutting speed)

-

Type:

Real

Defines the Cutting speed of the tool.

- MFG_SZ (Feedrate)

-

Type:

Real

Defines the Feedrate of the tool.

- MFG_PP (Depth of cut)

-

Type:

Real

Defines the Depth of cut of the tool.

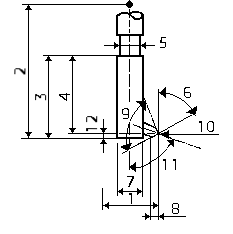

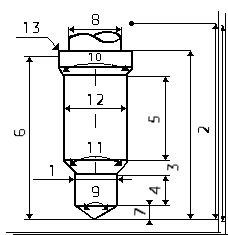

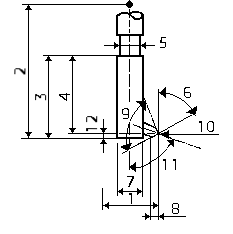

Center Drill

The MFG_NAME_BAS attribute for this tool is MfgCenterDrillTool.

This tool type has six compensation sites P1 to P6 (8-13), which are located on

the tool as shown below.

Manufacturing geometry attributes used in this resource are:

| Number on Image |

Description |

Parameter |

Attribute |

| 1 |

Cutting Diameter |

DC |

MFG_NOMINAL_DIAM |

| 2 |

Overall Length |

OAL |

MFG_OVERALL_LGTH |

| 3 |

Head Length |

LH |

MFG_LENGTH |

| 4 |

Depth of Cut Maximum |

APMX |

MFG_CUT_LENGTH |

| 5 |

Shank Diameter |

DMM |

MFG_BODY_DIAM |

| 6 |

Tool Cutting Edge Angle |

KAPR |

MFG_CUT_ANGLE |

| 7 |

Taper Angle |

STA_2 |

MFG_TAPER_ANGLE |

MfgCenterDrillTool resource attributes are described below.

Base Attributes

These attributes provide general information.

- MFG_NAME (Name)

-

Type:

String

Associates a name to the resource.

- MFG_COMMENT (Comment)

-

Type:

String

Associates a comment to the resource.

- MFG_TOOL_NUMBER (Tool number)

-

Type: Integer

Defines the tool number.

Geometry Attributes

These attributes characterize the tool shape and have an impact on the tool path

computation.

- MFG_NOMINAL_DIAM (Cutting diameter: DC)

-

Type:

Real

Defines the cutting diameter of the tool.

- MFG_OVERALL_LGTH (Overall length: OAL)

-

Type:

Real

Defines the total length of the tool.

- MFG_CUT_LENGTH (Depth of cut maximum: APMX)

-

Type:

Real

Defines the effective cutting length available on the active part of the tool.

- MFG_LENGTH (Head Length: HL)

-

Type:

Real

Defines the length of the external envelope of the active part of the tool.

- MFG_BODY_DIAM (Shank diameter: DMM)

-

Type:

Real

Defines the diameter of the external envelope of the non-active part of

the tool.

- MFG_CUT_ANGLE (Tool cutting edge angle: KAPR)

-

Type:

Real

Defines the cutting angle of the tool.

- MFG_TAPER_ANGLE (Taper angle: TA)

-

Type:

Real

Defines the taper angle on the tool.

Technology Attributes

These attributes provide technological information without any impact on the tool

path computation.

- MFG_MAX_MIL_LENGTH (Max machining length)

-

Type:

Real

Specifies the tool life in length units.

- MFG_MAX_MIL_TIME (Max life time)

-

Type:

Real

Specifies the tool life in time units.

- MFG_COOLNT_SNTX (Coolant syntax)

-

Type:

String

Specifies the coolant supply syntax.

- MFG_WEIGHT_SNTX (Weight syntax)

-

Type:

String

Specifies the tool weight syntax.

- MFG_MAX_CHIP_THICKNESS (Max Chip thickness)

Specifies a maximum thickness value for the chips to be removed

during machining. - MFG_MAX_VOL_RATE (Max Volume rate)

Specifies a maximum volume value for the chips to be removed during

machining. - MFG_MAX_POWER (Max Power)

Specifies a maximum power value required for the material to be

removed during machining.

Cutting Conditions Attributes

These attributes are used for feeds and speeds computation on the operation.

- MFG_VC (Cutting speed)

-

Type:

Real

Defines the Cutting speed of the tool.

- MFG_SZ (Feedrate)

-

Type:

Real

Defines the Feedrate of the tool.

- MFG_PP (Depth of cut)

-

Type:

Real

Defines the Depth of cut of the tool.

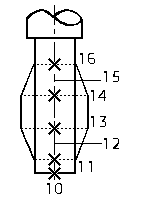

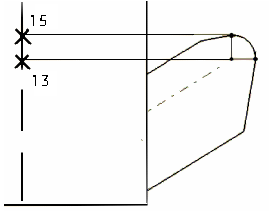

Multi Diameter Drill

The MFG_NAME_BAS attribute for this tool is MfgMultiDiamDrillTool.

This tool type has nine compensation sites P1 to P9 (14-22), which are located

on the tool as shown below.

Manufacturing geometry attributes used in this resource are:

| Number on Image |

Description |

Parameter |

Attribute |

| 1 |

Cutting Diameter |

DC |

MFG_NOMINAL_DIAM |

| 2 |

Overall Length |

OAL |

MFG_OVERALL_LGTH |

| 3 |

Head Length |

LH |

MFG_LENGTH |

| 4 |

Step Diameter Length |

SDL_2 |

MFG_LENGTH_1 |

| 5 |

Step Diameter Length |

SDL_3 |

MFG_LENGTH_2 |

| 6 |

Depth of cut maximum |

APMX |

MFG_CUT_LENGTH |

| 7 |

Point Length |

PL |

MFG_TL_TIP_LGTH |

| 8 |

Shank Diameter |

DMM |

MFG_BODY_DIAM |

| 9 |

Tool Cutting Edge Angle |

KAPR |

MFG_CUT_ANGLE |

| 10 |

Step Included Angle 2 |

STA_3 |

MFG_ANGLE2 |

| 11 |

Taper Angle |

STA_2 |

MFG_TAPER_ANGLE |

| 12 |

Cutting Diameter 2 |

DC_2 |

MFG_CHAMFR_DIAM1 |

| 13 |

Cutting Diameter 3 |

DC_3 |

MFG_CHAMFR_DIAM2 |

MfgMultiDiamDrillTool resource attributes are described below.

Base Attributes

These attributes provide general information.

- MFG_NAME (Name)

-

Type:

String

Associates a name to the resource.

- MFG_COMMENT (Comment)

-

Type:

String

Associates a comment to the resource.

- MFG_TOOL_NUMBER (Tool number)

-

Type: Integer

Defines the tool number.

- MFG_NB_OF_STAGES (Number of stages)

-

Type: Integer

Defines the number of stages of a multi-diameter drill.

Geometry Attributes

These attributes characterize the tool shape and have an impact on the tool path

computation.

- MFG_NOMINAL_DIAM (Cutting diameter: DC)

-

Type:

Real

Defines the cutting diameter of the tool.

- MFG_OVERALL_LGTH (Overall length: OAL)

-

Type:

Real

Defines the total length of the tool.

- MFG_CUT_LENGTH (Depth of cut maximum: APMX)

-

Type:

Real

Defines the effective cutting length available on the active part of the tool.

- MFG_LENGTH (Head Length: HL)

-

Type:

Real

Defines the length of the external envelope of the active part of the tool.

- MFG_BODY_DIAM (Shank diameter: DMM)

-

Type:

Real

Defines the diameter of the external envelope of the non-active part of

the tool.

- MFG_CUT_ANGLE (Tool cutting edge angle: KAPR)

-

Type:

Real

Defines the cutting angle of the tool.

- MFG_TL_TIP_LGTH (Point length: PL)

-

Type:

Real

Defines the part of the tool that cannot be used for cutting material at

the correct diameter (non-functional part of the tool).

- MFG_CHAMFR_DIAM1 (Cutting diameter 2: DC_2)

-

Type:

Real

Defines the diameter of the second part of a multi-diameter tool or

bore-and-chamfer tool.

- MFG_LENGTH_1 (Step diameter length: SDL_2)

-

Type:

Real

Defines the length of the first active part for tools such as multi-diameter

tool, bore-and-chamfer tool, and thread mill.

- MFG_TAPER_ANGLE (Taper angle: TA)

-

Type:

Real

Defines the taper angle on the tool.

- MFG_CHAMFR_DIAM2 (Cutting diameter 3: DC_3)

-

Type:

Real

Defines the diameter of the third part of a multi-diameter tool.

- MFG_LENGTH_2 (Step diameter length: SDL_3)

-

Type:

Real

Defines the length of the second active part of a multi-diameter

tool.

- MFG_ANGLE2 (Step included angle: STA_3)

-

Type:

Real

Defines the second cutting angle of the active part of a

multi-diameter tool or two-sides chamfering tool.

Technology Attributes

These attributes provide technological information without any impact on the tool

path computation.

- MFG_NB_OF_FLUTES (Number of flutes)

-

Type: Integer

Defines the number of flutes on the tool. In case of tools with separate

inserts, this is the number of inserts.

- MFG_WAY_OF_ROT (Way of rotation)

-

Type:

String

Possible values:

- RIGHT_HAND (Right hand)

- LEFT_HAND (Left hand)

Defines the rotation orientation of the current element. It should be compatible with spindle rotation

orientation.

- MFG_MACH_QUALITY (Machining quality)

-

Type:

String

Possible values:

- ROUGH (Rough)

- FINISH (Finish)

- EITHER (Either)

Defines the tool ability to machine in roughing or finishing mode.

- MFG_TOOTH_MAT (Tooth material)

-

Type:

String

Possible values:

- HIGH_SPEED_STEEL (High speed steel)

- COATED_HIGH_SPEED_STEEL (Coated high speed steel)

- CARBIDE (Carbide)

- COATED_CARBIDE (Coated carbide)

- OTHER (Other)

Defines the tooth material type.

- MFG_TOOTH_DES (Tooth description)

-

Type:

String

Allows to specify the tooth nature as a comment. For example, it

could be the supplier reference of the insert.

- MFG_TOOTH_MATDES (Tooth material desc.)

-

Type:

String

Allows to specify the tooth material by means of a comment. For

example, it could be the ISO designation for cutting materials or the reference

of the coating material.

- MFG_TL_RAKE_ANG (Tool rake angle)

-

Type:

Real

Defines the tool rake angle.

- MFG_MAX_MIL_LENGTH (Max machining length)

-

Type:

Real

Specifies the tool life in length units.

- MFG_MAX_MIL_TIME (Max life time)

-

Type:

Real

Specifies the tool life in time units.

- MFG_COOLNT_SNTX (Coolant syntax)

-

Type:

String

Specifies the coolant supply syntax.

- MFG_WEIGHT_SNTX (Weight syntax)

-

Type:

String

Specifies the tool weight syntax.

- MFG_MAX_CHIP_THICKNESS (Max Chip thickness)

Specifies a maximum thickness value for the chips to be removed

during machining. - MFG_MAX_VOL_RATE (Max Volume rate)

Specifies a maximum volume value for the chips to be removed during

machining. - MFG_MAX_POWER (Max Power)

Specifies a maximum power value required for the material to be

removed during machining.

Cutting Conditions Attributes

These attributes are used for feeds and speeds computation on the operation.

- MFG_VC (Cutting speed)

-

Type:

Real

Defines the Cutting speed of the tool.

- MFG_SZ (Feedrate)

-

Type:

Real

Defines the Feedrate of the tool.

- MFG_PP (Depth of cut)

-

Type:

Real

Defines the Depth of cut of the tool.

Boring and Chamfering Tool

The MFG_NAME_BAS attribute for this tool is MfgBoringAndChamferingTool.

Two Sides Chamfering Tool

The MFG_NAME_BAS attribute for this tool is MfgTwoSidesChamferingTool.

Counterbore Mill

The MFG_NAME_BAS attribute for this tool is MfgCounterboreMillTool.

This tool type has only one compensation site P1 (8), which is located on the

tool as shown below.

Manufacturing geometry attributes used in this resource are:

| Number on Image |

Description |

Parameter |

Attribute |

| 1 |

Cutting Diameter |

DC |

MFG_NOMINAL_DIAM |

| 2 |

Overall Length |

OAL |

MFG_OVERALL_LGTH |

| 3 |

Head Length |

LH |

MFG_LENGTH |

| 4 |

Depth of cut maximum |

APMX |

MFG_CUT_LENGTH |

| 5 |

Entry Diameter |

DE |

MFG_ENTRY_DIAM |

| 6 |

Shank Diameter |

DMM |

MFG_BODY_DIAM |

| 7 |

Point Length |

PL |

MFG_TL_TIP_LGTH |

MfgCounterboreMillTool resource attributes are described below.

Base Attributes

These attributes provide general information.

- MFG_NAME (Name)

-

Type:

String

Associates a name to the resource.

- MFG_COMMENT (Comment)

-

Type:

String

Associates a comment to the resource.

- MFG_TOOL_NUMBER (Tool number)

-

Type: Integer

Defines the tool number.

Geometry Attributes

These attributes characterize the tool shape and have an impact on the tool path

computation.

- MFG_NOMINAL_DIAM (Cutting diameter: DC)

-

Type:

Real

Defines the cutting diameter of the tool.

- MFG_OVERALL_LGTH (Overall length: OAL)

-

Type:

Real

Defines the total length of the tool.

- MFG_CUT_LENGTH (Depth of cut maximum: APMX)

-

Type:

Real

Defines the effective cutting length available on the active part of the tool.

- MFG_LENGTH (Head Length: HL)

-

Type:

Real

Defines the length of the external envelope of the active part of the tool.

- MFG_BODY_DIAM (Shank diameter: DMM)

-

Type:

Real

Defines the diameter of the external envelope of the non-active part of

the tool.

- MFG_ENTRY_DIAM (Entry diameter: DE)

-

Type:

Real

Defines the smallest diameter of the head of the tool.

- MFG_TL_TIP_LGTH (Tool tip length: ld)

-

Type:

Real

Defines the part of the tool that cannot be used for cutting material at

the correct diameter (non-functional part of the tool).

Technology Attributes

These attributes provide technological information without any impact on the tool

path computation.

- MFG_NB_OF_FLUTES (Number of flutes)

-

Type: Integer

Defines the number of flutes on the tool. In case of tools with separate

inserts, this is the number of inserts.

- MFG_WAY_OF_ROT (Way of rotation)

-

Type:

String

Possible values:

- RIGHT_HAND (Right hand)

- LEFT_HAND (Left hand)

Defines the rotation orientation of the current element. It should be compatible with spindle rotation

orientation.

- MFG_MACH_QUALITY (Machining quality)

-

Type:

String

Possible values:

- ROUGH (Rough)

- FINISH (Finish)

- EITHER (Either)

Defines the tool ability to machine in roughing or finishing mode.

- MFG_COMPOSITION (Composition)

-

Type:

String

Possible values:

- ONE_PIECE (One piece)

- INSERT_HOLDER (Insert holder)

Specifies if the tool is an inserted one.

- MFG_TOOTH_MAT (Tooth material)

-

Type:

String

Possible values:

- HIGH_SPEED_STEEL (High speed steel)

- COATED_HIGH_SPEED_STEEL (Coated high speed steel)

- CARBIDE (Carbide)

- COATED_CARBIDE (Coated carbide)

- OTHER (Other)

Defines the tooth material type.

- MFG_TL_RAKE_ANG (Tool rake angle)

-

Type:

Real

Defines the tool rake angle.

- MFG_MAX_PLNG_ANG (Max plunge angle)

-

Type:

Real

Defines the plunge ability of the tool. When the tool is able to plunge

along its axis, the maximum plunge angle is equal to 90 degrees.

- MFG_MAX_MIL_LENGTH (Max machining length)

-

Type:

Real

Specifies the tool life in length units.

- MFG_MAX_MIL_TIME (Max life time)

-

Type:

Real

Specifies the tool life in time units.

- MFG_COOLNT_SNTX (Coolant syntax)

-

Type:

String

Specifies the coolant supply syntax.

- MFG_WEIGHT_SNTX (Weight syntax)

-

Type:

String

Specifies the tool weight syntax.

- MFG_MAX_CHIP_THICKNESS (Max Chip thickness)

Specifies a maximum thickness value for the chips to be removed

during machining. - MFG_MAX_VOL_RATE (Max Volume rate)

Specifies a maximum volume value for the chips to be removed during

machining. - MFG_MAX_POWER (Max Power)

Specifies a maximum power value required for the material to be

removed during machining.

Cutting Conditions Attributes

These attributes are used for feeds and speeds computation on the operation.

- MFG_VC (Cutting speed)

-

Type:

Real

Defines the Cutting speed of the tool.

- MFG_SZ (Feedrate)

-

Type:

Real

Defines the Feedrate of the tool.

- MFG_PP (Depth of cut)

-

Type:

Real

Defines the Depth of cut of the tool.

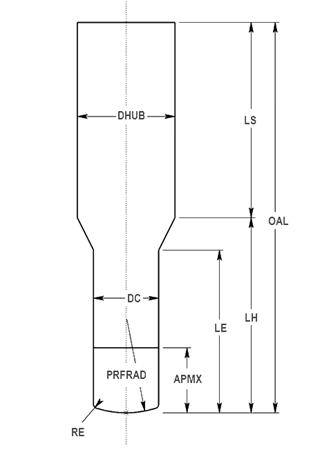

End Mill

The MFG_NAME_BAS attribute for this tool is MfgEndMillTool.

This tool type has two compensation sites:

- P1 (7) is located at the extremity of the tool

- P2 (8) is located a distance RE (corner radius) from P1 along the tool

axis.

Manufacturing geometry attributes used in this resource are:

| Number on Image |

Description |

Parameter |

Attribute |

| 1 |

Cutting Diameter |

DC |

MFG_NOMINAL_DIAM |

| 2 |

Overall Length |

OAL |

MFG_OVERALL_LGTH |

| 3 |

Head Length |

LH |

MFG_LENGTH |

| 4 |

Depth of Cut Maximum |

APMX |

MFG_CUT_LENGTH |

| 5 |

Corner Radius |

RE |

MFG_CORNER_RAD |

| 6 |

Shank Diameter |

DMM |

MFG_BODY_DIAM |

| |

Non Cutting Diameter |

|

MFG_NON_CUT_DIAM |

MfgEndMillTool resource attributes are described below.

Base Attributes

These attributes provide general information.

- MFG_NAME (Name)

-

Type:

String

Associates a name to the resource.

- MFG_COMMENT (Comment)

-

Type:

String

Associates a comment to the resource.

- MFG_TOOL_NUMBER (Tool number)

-

Type: Integer

Defines the tool number.

- MFG_BALL_TYPE (Ball-end tool)

-

Type: Boolean (Yes/No)

Defines the tool as being ball-end.

Geometry Attributes

These attributes characterize the tool shape and have an impact on the tool path

computation.

- MFG_NOMINAL_DIAM (Cutting diameter: DC)

-

Type:

Real

Defines the cutting diameter of the tool.

- MFG_CORNER_RAD (Corner radius: RE)

-

Type:

Real

Defines the radius of the cutting shape of the tool.

- MFG_OVERALL_LGTH (Overall length: OAL)

-

Type:

Real

Defines the total length of the tool.

- MFG_CUT_LENGTH (Depth of cut maximum: APMX)

-

Type:

Real

Defines the effective cutting length available on the active part of the tool.

- MFG_LENGTH (Head Length: HL)

-

Type:

Real

Defines the length of the external envelope of the active part of the tool.

- MFG_BODY_DIAM (Shank diameter: DMM)

-

Type:

Real

Defines the diameter of the external envelope of the non-active part of

the tool.

- MFG_TOOL_CORE_DIAMETER (Non cutting diameter)

-

Type:

Real

Defines the diameter of the non-cutting part (core) of the tool. This can

be useful in operations such as Roughing, Pocketing, and Multi-Axis Helix

Machining.

Technology Attributes

These attributes provide technological information without any impact on the tool

path computation.

- MFG_NB_OF_FLUTES (Number of flutes)

-

Type: Integer

Defines the number of flutes on the tool. In case of tools with separate

inserts, this is the number of inserts.

- MFG_WAY_OF_ROT (Way of rotation)

-

Type:

String

Possible values:

- RIGHT_HAND (Right hand)

- LEFT_HAND (Left hand)

Defines the rotation orientation of the current element. It should be compatible with spindle rotation

orientation.

- MFG_MACH_QUALITY (Machining quality)

-

Type:

String

Possible values:

- ROUGH (Rough)

- FINISH (Finish)

- EITHER (Either)

Defines the tool ability to machine in roughing or finishing mode.

- MFG_COMPOSITION (Composition)

-

Type:

String

Possible values:

- ONE_PIECE (One piece)

- INSERT_HOLDER (Insert holder)

Specifies if the tool is an inserted one.

- MFG_TOOTH_MAT (Tooth material)

-

Type:

String

Possible values:

- HIGH_SPEED_STEEL (High speed steel)

- COATED_HIGH_SPEED_STEEL (Coated high speed steel)

- CARBIDE (Carbide)

- COATED_CARBIDE (Coated carbide)

- OTHER (Other)

Defines the tooth material type.

- MFG_TOOTH_DES (Tooth description)

-

Type:

String

Allows to specify the tooth nature as a comment. For example, it

could be the supplier reference of the insert.

- MFG_TOOTH_MATDES (Tooth material desc.)

-

Type:

String

Allows to specify the tooth material by means of a comment. For

example, it could be the ISO designation for cutting materials or the reference

of the coating material.

- MFG_TL_RAKE_ANG (Tool rake angle)

-

Type:

Real

Defines the tool rake angle.

- MFG_MAX_PLNG_ANG (Max plunge angle)

-

Type:

Real

Defines the plunge ability of the tool. When the tool is able to plunge

along its axis, the maximum plunge angle is equal to 90 degrees.

- MFG_MAX_MIL_LENGTH (Max machining length)

-

Type:

Real

Specifies the tool life in length units.

- MFG_MAX_MIL_TIME (Max life time)

-

Type:

Real

Specifies the tool life in time units.

- MFG_COOLNT_SNTX (Coolant syntax)

-

Type:

String

Specifies the coolant supply syntax.

- MFG_WEIGHT_SNTX (Weight syntax)

-

Type:

String

Specifies the tool weight syntax.

- MFG_MAX_CHIP_THICKNESS (Max Chip thickness)

Specifies a maximum thickness value for the chips to be removed

during machining. - MFG_MAX_VOL_RATE (Max Volume rate)

Specifies a maximum volume value for the chips to be removed during

machining. - MFG_MAX_POWER (Max Power)

Specifies a maximum power value required for the material to be

removed during machining.

Cutting Conditions Attributes

These attributes are used for feeds and speeds computation on the operation.

- MFG_VC_FINISH (Finishing cutting speed)

-

Type:

Real

Defines the Finishing cutting speed of the tool.

- MFG_SZ_FINISH (Finishing feedrate per tooth)

-

Type:

Real

Defines the Finishing feedrate per tooth of the tool.

- MFG_AA_FINISH (Axial depth of cut for finish)

-

Type:

Real

Defines the Axial depth of cut for finish of the tool.

- MFG_AR_FINISH (Radial depth of cut for finish)

-

Type:

Real

Defines the Radial depth of cut for finish of the tool.

- MFG_VC_ROUGH (Roughing cutting speed)

-

Type:

Real

Defines the Roughing cutting speed of the tool.

- MFG_SZ_ROUGH (Roughing feedrate per tooth)

-

Type:

Real

Defines the Roughing feedrate per tooth of the tool.

- MFG_AA_ROUGH (Axial depth of cut for rough)

-

Type:

Real

Defines the Axial depth of cut for rough of the tool.

- MFG_AR_ROUGH (Radial depth of cut for rough)

-

Type:

Real

Defines the Radial depth of cut for rough of the tool.

Face Mill

The MFG_NAME_BAS attribute for this tool is MfgFaceMillTool.

This tool type has only one compensation site P1 (9), which is located at the

extremity of the tool.

Manufacturing geometry attributes used in this resource are:

| Number on Image |

Description |

Parameter |

Attribute |

| 1 |

Cutting Diameter |

DC |

MFG_NOMINAL_DIAM |

| 2 |

Cutting Diameter Max |

DCX |

MFG_OUTSIDE_DIAM |

| 3 |

Overall Length |

OAL |

MFG_OVERALL_LGTH |

| 4 |

Head Length |

LH |

MFG_LENGTH |

| 5 |

Depth of cut maximum |

APMX |

MFG_CUT_LENGTH |

| 6 |

Corner Radius |

RE |

MFG_CORNER_RAD |

| 7 |

Shank Diameter |

DMM |

MFG_BODY_DIAM |

| 8 |

Tool Cutting Edge Angle |

KAPR |

MFG_CUT_ANGLE |

| |

Non Cutting Diameter |

|

MFG_NON_CUT_DIAM |

MfgFaceMillTool resource attributes are described below.

Base Attributes

These attributes provide general information.

- MFG_NAME (Name)

-

Type:

String

Associates a name to the resource.

- MFG_COMMENT (Comment)

-

Type:

String

Associates a comment to the resource.

- MFG_TOOL_NUMBER (Tool number)

-

Type: Integer

Defines the tool number.

Geometry Attributes

These attributes characterize the tool shape and have an impact on the tool path

computation.

- MFG_NOMINAL_DIAM (Cutting diameter: DC)

-

Type:

Real

Defines the cutting diameter of the tool.

- MFG_CORNER_RAD (Corner radius: RE)

-

Type:

Real

Defines the radius of the cutting shape of the tool.

- MFG_OVERALL_LGTH (Overall length: OAL)

-

Type:

Real

Defines the total length of the tool.

- MFG_CUT_LENGTH (Depth of cut maximum: APMX)

-

Type:

Real

Defines the effective cutting length available on the active part of the tool.

- MFG_LENGTH (Head Length: HL)

-

Type:

Real

Defines the length of the external envelope of the active part of the tool.

- MFG_BODY_DIAM (Shank diameter: DMM)

-

Type:

Real

Defines the diameter of the external envelope of the non-active part of

the tool.

- MFG_OUTSIDE_DIAM (Cutting diameter max: DCX)

-

Type:

Real

Defines the diameter of the external envelope of the tool active part

for tools such as face mills, countersinks and thread mills.

- MFG_CUT_ANGLE (Tool cutting edge angle: KAPR)

-

Type:

Real

Defines the cutting angle of the tool.

- MFG_TOOL_CORE_DIAMETER (Non cutting diameter)

-

Type:

Real

Defines the diameter of the non-cutting part (core) of the tool. This can

be useful in operations such as Roughing, Pocketing, and Multi-Axis Helix

Machining.

Technology Attributes

These attributes provide technological information without any impact on the tool

path computation.

- MFG_NB_OF_FLUTES (Number of flutes)

-

Type: Integer

Defines the number of flutes on the tool. In case of tools with separate

inserts, this is the number of inserts.

- MFG_WAY_OF_ROT (Way of rotation)

-

Type:

String

Possible values:

- RIGHT_HAND (Right hand)

- LEFT_HAND (Left hand)

Defines the rotation orientation of the current element. It should be compatible with spindle rotation

orientation.

- MFG_MACH_QUALITY (Machining quality)

-

Type:

String

Possible values:

- ROUGH (Rough)

- FINISH (Finish)

- EITHER (Either)

Defines the tool ability to machine in roughing or finishing mode.

- MFG_COMPOSITION (Composition)

-

Type:

String

Possible values:

- ONE_PIECE (One piece)

- INSERT_HOLDER (Insert holder)

Specifies if the tool is an inserted one.

- MFG_TOOTH_MAT (Tooth material)

-

Type:

String

Possible values:

- HIGH_SPEED_STEEL (High speed steel)

- COATED_HIGH_SPEED_STEEL (Coated high speed steel)

- CARBIDE (Carbide)

- COATED_CARBIDE (Coated carbide)

- OTHER (Other)

Defines the tooth material type.

- MFG_TOOTH_DES (Tooth description)

-

Type:

String

Allows to specify the tooth nature as a comment. For example, it

could be the supplier reference of the insert.

- MFG_TOOTH_MATDES (Tooth material desc.)

-

Type:

String

Allows to specify the tooth material by means of a comment. For

example, it could be the ISO designation for cutting materials or the reference

of the coating material.

- MFG_TL_RAKE_ANG (Tool rake angle)

-

Type:

Real

Defines the tool rake angle.

- MFG_MAX_PLNG_ANG (Max plunge angle)

-

Type:

Real

Defines the plunge ability of the tool. When the tool is able to plunge

along its axis, the maximum plunge angle is equal to 90 degrees.

- MFG_MAX_MIL_LENGTH (Max machining length)

-

Type:

Real

Specifies the tool life in length units.

- MFG_MAX_MIL_TIME (Max life time)

-

Type:

Real

Specifies the tool life in time units.

- MFG_COOLNT_SNTX (Coolant syntax)

-

Type:

String

Specifies the coolant supply syntax.

- MFG_WEIGHT_SNTX (Weight syntax)

-

Type:

String

Specifies the tool weight syntax.

- MFG_MAX_CHIP_THICKNESS (Max Chip thickness)

Specifies a maximum thickness value for the chips to be removed

during machining. - MFG_MAX_VOL_RATE (Max Volume rate)

Specifies a maximum volume value for the chips to be removed during

machining. - MFG_MAX_POWER (Max Power)

Specifies a maximum power value required for the material to be

removed during machining.

Cutting Conditions Attributes

These attributes are used for feeds and speeds computation on the operation.

- MFG_VC_FINISH (Finishing cutting speed)

-

Type:

Real

Defines the Finishing cutting speed of the tool.

- MFG_SZ_FINISH (Finishing feedrate per tooth)

-

Type:

Real

Defines the Finishing feedrate per tooth of the tool.

- MFG_AA_FINISH (Axial depth of cut for finish)

-

Type:

Real

Defines the Axial depth of cut for finish of the tool.

- MFG_AR_FINISH (Radial depth of cut for finish)

-

Type:

Real

Defines the Radial depth of cut for finish of the tool.

- MFG_VC_ROUGH (Roughing cutting speed)

-

Type:

Real

Defines the Roughing cutting speed of the tool.

- MFG_SZ_ROUGH (Roughing feedrate per tooth)

-

Type:

Real

Defines the Roughing feedrate per tooth of the tool.

- MFG_AA_ROUGH (Axial depth of cut for rough)

-

Type:

Real

Defines the Axial depth of cut for rough of the tool.

- MFG_AR_ROUGH (Radial depth of cut for rough)

-

Type:

Real

Defines the Radial depth of cut for rough of the tool.

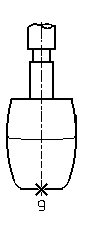

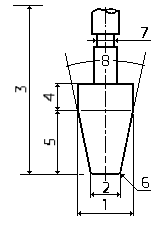

Conical Mill

The MFG_NAME_BAS attribute for this tool is MfgConicalMillTool.

This tool type has three compensation sites P1 to P3 (9-11), which are located on

the tool as shown below.

Manufacturing geometry attributes used in this resource are:

| Number on Image |

Description |

Parameter |

Attribute |

| 1 |

Cutting Diameter |

DC |

MFG_NOMINAL_DIAM |

| 2 |

Entry Diameter |

DE |

MFG_ENTRY_DIAM |

| 3 |

Overall Length |

OAL |

MFG_OVERALL_LGTH |

| 4 |

Head Length |

LH |

MFG_LENGTH |

| 5 |

Depth of Cut Maximum |

APMX |

MFG_CUT_LENGTH |

| 6 |

Corner Radius |

RE |

MFG_CORNER_RAD |

| 7 |

Shank Diameter |

DMM |

MFG_BODY_DIAM |

| 8 |

Tool Cutting Edge Angle |

KAPR |

MFG_CUT_ANGLE |

MfgConicalMillTool resource attributes are described below.

Base Attributes

These attributes provide general information.

- MFG_NAME (Name)

-

Type:

String

Associates a name to the resource.

- MFG_COMMENT (Comment)

-

Type:

String

Associates a comment to the resource.

- MFG_TOOL_NUMBER (Tool number)

-

Type: Integer

Defines the tool number.

- MFG_BALL_TYPE (Ball-end tool)

-

Type: Boolean (Yes/No)

Defines the tool as being ball-end.

Geometry Attributes

These attributes characterize the tool shape and have an impact on the tool path

computation.

- MFG_NOMINAL_DIAM (Cutting diameter: DC)

-

Type:

Real

Defines the cutting diameter of the tool.

- MFG_CORNER_RAD (Corner radius: RE)

-

Type:

Real

Defines the radius of the cutting shape of the tool.

- MFG_OVERALL_LGTH (Overall length: OAL)

-

Type:

Real

Defines the total length of the tool.

- MFG_CUT_LENGTH (Depth of cut maximum: APMX

-

Type:

Real

Defines the effective cutting length available on the active part of the tool.

- MFG_LENGTH (Head Length: HL)

-

Type:

Real

Defines the length of the external envelope of the active part of the tool.

- MFG_BODY_DIAM (Shank diameter: DMM)

-

Type:

Real

Defines the diameter of the external envelope of the non-active part of

the tool.

- MFG_ENTRY_DIAM (Entry diameter: DE)

-

Type:

Real

Defines the smallest diameter of the head of the tool.

- MFG_CUT_ANGLE (Tool cutting edge angle: KAPR)

-

Type:

Real

Defines the cutting angle of the tool.

Technology Attributes

These attributes provide technological information without any impact on the tool

path computation.

- MFG_NB_OF_FLUTES (Number of flutes)

-

Type: Integer

Defines the number of flutes on the tool. In case of tools with separate

inserts, this is the number of inserts.

- MFG_WAY_OF_ROT (Way of rotation)

-

Type:

String

Possible values:

- RIGHT_HAND (Right hand)

- LEFT_HAND (Left hand)

Defines the rotation orientation of the current element. It should be compatible with spindle rotation

orientation.

- MFG_MACH_QUALITY (Machining quality)

-

Type:

String

Possible values:

- ROUGH (Rough)

- FINISH (Finish)

- EITHER (Either)

Defines the tool ability to machine in roughing or finishing mode.

- MFG_COMPOSITION (Composition)

-

Type:

String

Possible values:

- ONE_PIECE (One piece)

- INSERT_HOLDER (Insert holder)

Specifies if the tool is an inserted one.

- MFG_TOOTH_MAT (Tooth material)

-

Type:

String

Possible values:

- HIGH_SPEED_STEEL (High speed steel)

- COATED_HIGH_SPEED_STEEL (Coated high speed steel)

- CARBIDE (Carbide)

- COATED_CARBIDE (Coated carbide)

- OTHER (Other)

Defines the tooth material type.

- MFG_TOOTH_DES (Tooth description)

-

Type:

String

Allows to specify the tooth nature as a comment. For example, it

could be the supplier reference of the insert.

- MFG_TOOTH_MATDES (Tooth material desc.)

-

Type:

String

Allows to specify the tooth material by means of a comment. For

example, it could be the ISO designation for cutting materials or the reference

of the coating material.

- MFG_TL_RAKE_ANG (Tool rake angle)

-

Type:

Real

Defines the tool rake angle.

- MFG_MAX_PLNG_ANG (Max plunge angle)

-

Type:

Real

Defines the plunge ability of the tool. When the tool is able to plunge

along its axis, the maximum plunge angle is equal to 90 degrees.

- MFG_MAX_MIL_LENGTH (Max machining length)

-

Type:

Real

Specifies the tool life in length units.

- MFG_MAX_MIL_TIME (Max life time)

-

Type:

Real

Specifies the tool life in time units.

- MFG_COOLNT_SNTX (Coolant syntax)

-

Type:

String

Specifies the coolant supply syntax.

- MFG_WEIGHT_SNTX (Weight syntax)

-

Type:

String

Specifies the tool weight syntax.

- MFG_MAX_CHIP_THICKNESS (Max Chip thickness)

Specifies a maximum thickness value for the chips to be removed

during machining. - MFG_MAX_VOL_RATE (Max Volume rate)

Specifies a maximum volume value for the chips to be removed during

machining. - MFG_MAX_POWER (Max Power)

Specifies a maximum power value required for the material to be

removed during machining.

Cutting Conditions Attributes

These attributes are used for feeds and speeds computation on the operation.

- MFG_VC_FINISH (Finishing cutting speed)

-

Type:

Real

Defines the Finishing cutting speed of the tool.

- MFG_SZ_FINISH (Finishing feedrate per tooth)

-

Type:

Real

Defines the Finishing feedrate per tooth of the tool.

- MFG_AA_FINISH (Axial depth of cut for finish)

-

Type:

Real

Defines the Axial depth of cut for finish of the tool.

- MFG_AR_FINISH (Radial depth of cut for finish)

-

Type:

Real

Defines the Radial depth of cut for finish of the tool.

- MFG_VC_ROUGH (Roughing cutting speed)

-

Type:

Real

Defines the Roughing cutting speed of the tool.

- MFG_SZ_ROUGH (Roughing feedrate per tooth)

-

Type:

Real

Defines the Roughing feedrate per tooth of the tool.

- MFG_AA_ROUGH (Axial depth of cut for rough)

-

Type:

Real

Defines the Axial depth of cut for rough of the tool.

- MFG_AR_ROUGH (Radial depth of cut for rough)

-

Type:

Real

Defines the Radial depth of cut for rough of the tool.

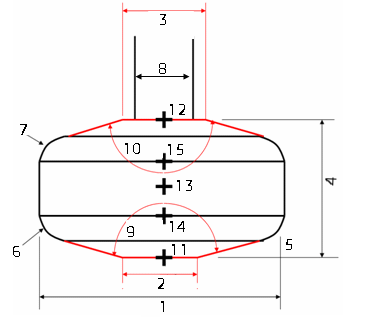

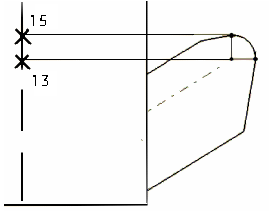

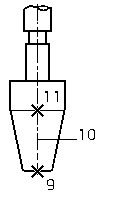

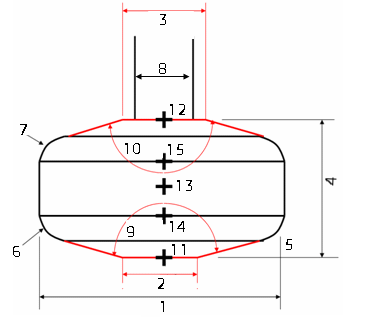

T-Slotter

The MFG_NAME_BAS attribute for this tool is MfgTSlotterTool.

This tool type has five compensation sites, which are located on the tool as

shown below:

- P1 (11) is located at the extremity of the tool.

- P2 (12) is located a distance l from P1 along the tool axis.

- P3 (13) is located a distance l/2 from P1 along the tool axis. For a

ball-end tool, P3 is located at a distance DC2 from P1 along the tool

axis.

- P4 (14) is located a distance RE (corner radius) from P1 along the tool

axis.

- P5 (15) is located a distance (LH-RE2) from P1 along the tool axis.

Manufacturing geometry attributes used in this resource are:

| Number on Image |

Description |

Parameter |

Attribute |

| 1 |

Cutting Diameter |

DC |

MFG_NOMINAL_DIAM |

| 2 |

Bottom Cutting Diameter |

DC1 |

MFG_LOWER_DIAM |

| 3 |

Bottom Cutting Diameter |

DC2 |

MFG_UPPER_DIAM |

| 4 |

Overall Length |

OAL |

MFG_OVERALL_LGTH |

| 5 |

Head Length |

LH |

MFG_LENGTH |

| 6 |

Corner Radius |

RE |

MFG_CORNER_RAD |

| 7 |

Upper Corner Radius |

RE2 |

MFG_CORNER_RAD_2 |

| 8 |

Shank Diameter |

DMM |

MFG_BODY_DIAM |

| 9 |

Bottom Tool Cutting Edge Angle |

KAPR1 |

MFG_LOWER_ANGLE |

| 10 |

Top Tool Cutting Edge Angle |

KAPR2 |

MFG_UPPER_ANGLE |

MfgTSlotterTool resource attributes are described below.

Base Attributes

These attributes provide general information.

- MFG_NAME (Name)

-

Type:

String

Associates a name to the resource.

- MFG_COMMENT (Comment)

-

Type:

String

Associates a comment to the resource.

- MFG_TOOL_NUMBER (Tool number)

-

Type: Integer

Defines the tool number.

- MFG_BALL_TYPE (Ball-end tool)

-

Type: Boolean (Yes/No)

Defines the tool as being ball-end.