Insert a Copy-Transformation Instruction from the Program Tab

You can use Copy-Transformation Instruction in the Copy/Tracut Operations sub-tab of the Program tab.

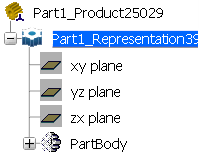

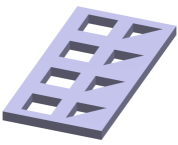

- In a product like this one,

-

Select a machining

app

then the

Programming

section.

An empty Manufacturing Cell is created with an Activities Process Tree.

-

Create a generic machine or assign a

machine from the database.

As soon as a machine is assigned to the Manufacturing Cell, a Part Operation and a Manufacturing Program are created in the Activities Process Tree.

-

Alternatively, open an existing

Machining Process

or

PPR Context.

By default, the Activities Process Tree is available.

-

Select a machining

app

then the

Programming

section.

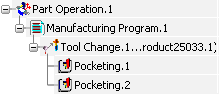

- Create Pocketing

operation:

- Select Prismatic Machining section.

- Click

Pocketing and create a first Pocketing operation

on the first square cut-out.

Pocketing and create a first Pocketing operation

on the first square cut-out. - Create a second Pocketing

operation using the same tool on the first triangular

cut-out.

When creating these pockets, make sure that the Island Detection context menu menu command is not active before you select the pocket bottom.

- Right-click the manufacturing program

and select Compute Tool Path.

- Select the Compute if necessary option in the pop-up that appears.

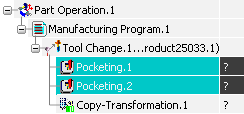

- Select the second Pocketing operation in the Manufacturing Program.

- Click Copy-Transformation Instruction

.

.

A Copy-Transformation is inserted in the Manufacturing Program after Pocketing.2 and the Copy-Transformation dialog box appears.

- Click Copy-Transformation Instruction

- In the dialog box, click

Add Operations

:

:- Using Ctrl, select the two Pocketing operations in the Activities Process Tree.

- Double-click in the work area to end the selection and revert to the dialog box.

Note: The selected machining operations must have the same tooling.The Copy-Transformation Instruction is applied to these two machining operations.

The dialog box is updated:- Move Up

and Move Down

and Move Down

allow you to move the selected machining operation up or down

in the list.

allow you to move the selected machining operation up or down

in the list. -

Delete

allows you to delete the selected Machining Operations.

allows you to delete the selected Machining Operations.

- Define the Copy-Transformation Instruction, for example:

- Click Display or

Simulate

to visualize the tool path resulting from the defined

Copy-Transformation Instruction.

Note: See Displaying Tool Path

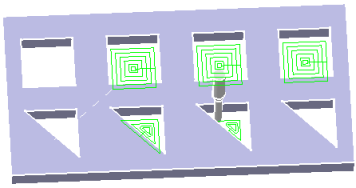

With the Each operation N times Ordering setting, the transformation is applied to the 3 square cut-outs first then to the 3 triangular cut-outs.

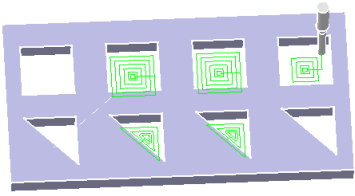

With the All operations N times Ordering setting, the transformation is applied to the first set of square and triangular cut-outs, then the second set, and finally the third set.

- Click OK to create the Copy-Transformation Instruction in the manufacturing program.