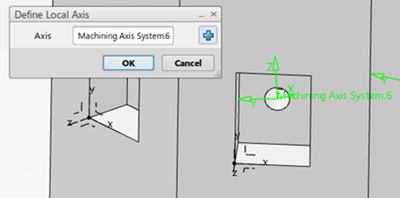

Assign a Machining Axis System

You can assign a local machining axis system to one or more operations using Assign Local Axis System. You can also use this command to create a new machining axis system and assign it to the selected operation.

Assign Local Axis System is available for all machining operations except turning operations.

The machining axis system is assigned to the operation. All the calculations and output generated for that operation are based on the selected machining axis system.

| Tip:

To remove a machining axis system, right-click the operation with a machining axis system assigned and select Remove Local Axis System.

Remove Local Axis System is available only if the selected machining operation has a local machining axis system assigned. |