-

From any product or 3D part

-

Select a machining

app

then the

Programming

section.

An empty

Manufacturing

Cell is created with an

Activities Process

Tree.

-

Create a generic machine or assign a

machine from the database.

As soon as a

machine is assigned to the

Manufacturing

Cell,

a

Part Operation

and a

Manufacturing Program

are created in the

Activities Process

Tree.

-

Alternatively, open an existing

Machining Process

or

PPR Context.

By default, the

Activities Process

Tree

is available.

-

Click any Machining Operation icon and select a Manufacturing Program or another Machining Operation in the Activities Process

Tree.

- The dialog box opens at the Geometry tab.

- This page includes a sensitive icon to help you specify the geometry to be machined.

The red status light on the tab indicates that you must select the geometry in order

to create the operation.

Notes:

- Each Machining Operation offers its own sensitive icon. In addition, the icon is slightly different if you

are using a rework area or a slope area and has fewer parameters.

- If you are editing a rework or a slope area, additional information is displayed,

indicating which type of subset you are working on. This field is not editable.

-

Click Information to get details on the parameters that were

defined with the rework area.

-

Select some geometry.

Only the part to machine is mandatory but you can also select :

- The check element,

- The safety plane,

- A top plane,

- A bottom plane,

- A start plane,

- An end plane,

- Inner points,

- The limiting contour,

- The offset on the part (double-click Offset

on part:0mm),

- The offset on the check element (double-click Offset on

check:0mm).

Refer to each Machining Operation for more details.

The corresponding portion of the icon turns from red to green. Note:

The status

color codes are as follows:

- Green (or the current value of Valuated parameters): all

the requested data are defined,

- Orange (or the current value of Optional parameters): data

are defined, but modifications may be necessary,

- Red (or the current value of Required parameters): data

definition is required.

- The colors of Valuated parameters, Optional

parameters, Required parameters are defined in

.

-

Select another geometry:

-

Click a face definition area and use the Faces Selection tab,

-

Click a contour definition area and use the Edges Selection

tab,

-

Right-click an element definition area: choose Body(ies) if

you wish to machine a whole part and not just an area on it, or Select

zones if you wish to select zones.

-

In the Feature pull-down window, choose a pre-defined area

like: Surface Feature.4.

Notes:

- Use Offset Groups and Features

when defining geometry.

- The types of selection by default (reached by clicking a sensitive zone) are

adapted to the types of the elements to select (bodies for a part to machine,

but faces for check elements, for instance).

- The context menu 's vary also with the type of elements to select.

-

Define planes by selecting a point or a plane in the work area.

-

Set an Offset on all of the planes using the context menu over each plane. The offset is either positive or negative and is previewed in the

work area

before it is validated.

In the case of imposed planes, the offset value applies to all of

the planes you have imposed. The tool passes through all of the planes defined by the

offset and not through the planes that are imposed. One advantage of this is that if

the top surface of the part is flat and you have defined an Offset on part of, for

example of 1mm, you can define the same offset on the imposed planes so as to ensure

that there are no residual material remaining on the top surface.

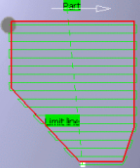

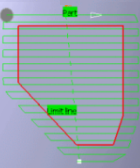

-

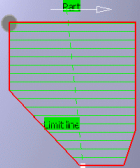

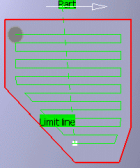

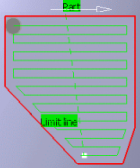

Use Part

Autolimit and the limiting contour individually or together to define the

area you want to machine.

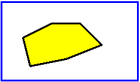

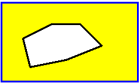

In the pictures:

- The blue outline is the part edge,

- The yellow part is the area that is to be machined,

- The black line is the limiting contour:

- If you activate Part Autolimit, the yellow area (shown

in the image) is machined and the tool contact point stops on the edge of the

part (the tool does not go beyond the edge of the part).

- If you use a limiting contour, only the area inside the limiting contour is

machined.

- If you wish to machine the area outside the limiting contour, choose

Outside as the Side to

machine.

-

Once the limiting contour is defined, you can also define the following

parameters:

- Stop

position: Specifies where the tool stops:

- Outside stops the tool outside the limit line,

- Inside stops the tool inside the limit line,

- On stops the tool on the limit line.

- Offset : Starting from the previous

position (Inside, Outside,

On) a positive value of the offset increases the area to

machine, a negative value reduce this area:

- Stop position=On, no Offset

- Stop position=On, Positive Offset

- Stop position=On, Negative Offset

- Stop position=Inside, no Offset

- Stop position=Inside, Positive Offset

- Stop position=Inside, Negative Offset

- Stop position=Outside, no Offset

- Stop position=Outside, Positive Offset

- Stop position=Outside, Negative Offset

You can now either:

- Run the operation on the part,

- Store the operation that you have just defined, or

- Define other parameters in the machining strategy, tool data, speeds and rates, or

macro data tabs first.

|