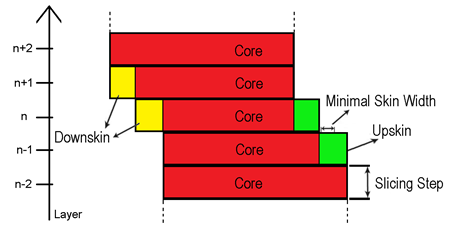

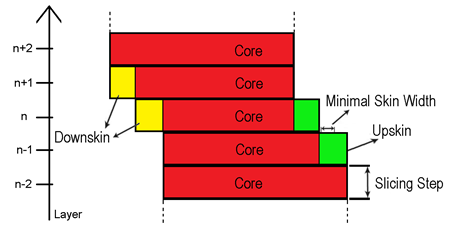

A skin surface is an area on a layer of a part, with no material above or below.

There are several types of skin surfaces:

- Upskin: upward facing surface of a part with

no material above.

- Downskin: downward facing surface of a part

with no material below.

- Core: corresponds to the surface between an

upskin and downskin surface.

Skin surfaces are automatically detected on a part when you create a slicing operation. You

can generate a tool path on any type of skin surface using the general tool path parameters,

and order them in a sequence.

The following skin surfaces parameters are available:

| Parameter |

Description |

| Minimal Skin Width

|

The specific value that a surface is considered upskin or

downskin. By default, the value is 0.1mm. |

| Number of Layers

|

The specific number of upskin or downskin layers. |