Fasten Item Planning / Management | ||

| ||

Fasteners Management Preferences

Fasteners management settings are in the Preferences.

Tiles in the Process Editor

A tile for weld in the Process Editor is similar with the tile for fasten. Only the icon on the tile is different.

Auxiliary Viewer

The Auxiliary Viewer takes into account the umber of fasteners and fasten items.

- Assigned: 0 + number of fastens

- Unassigned: 67 + number of fasteners

Second local mode of display mode in the auxiliary viewer visualizes the connected parts with the fastener when selecting a fasten or weld item.

- No resulting product or unloaded resulting product on a fasten item: implemented products

- Fasten ->Fastener -> Connected parts

- Resulting product on a fasten: resulting products

- Fasten -> Fastener è Connected parts -> Implementing manufactured parts -> Resulting products of manufactured parts

Part List

Fasteners are displayed in the Product tab or Item tab of the Part List.

Fasten items are displayed in the Item tab of the Part List.

Generate MBOM

Rule-based MBOM Generation accepts only None keyword for fasteners. Not allowing other keywords for fasteners.

Rule-based MBOM Generation follows the app preference. When the first preference of the Fasteners management is ON, the Item Type is seen as:

- Bead Fasteners: Weld.

- Other Fasteners: Fasten.

There are several PLM attributes on Weld item reference, and it is possible to update values through the Attribute Rule.

Compute/Update Resulting Product

Loading Resulting Products on Demand

Enterprise Knowledge Language (EKL)

You can instantiate the Weld item through the EKL.

Let hProcessOcc(MfgProcessOccurrence) /* Input */

Let hNewItemRef(DELFmiFunctionReference)

If hProcessOcc <> NULL

{

hNewItemRef = CreateProcessReference(“HeavyIndustryWeld”)

if hNewItemRef <> NULL

{

hProcessOcc->InsertPredecessor(hNewItemRef)

}

}

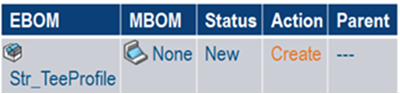

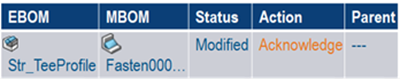

Synchronization Manager

The first preference of the Fasteners management in the App Preferences is ON. The Synchronization Manager displays 5 cases. However, this does not mention a Up-to-date case as further action is required. The differences between Preferences ON/OFF are either Weld or Fasten item.

- New Case - Create action is available for

New status using Compute on a fastener

row.

Synchronizing - Status is Up To Date and the Action is None.

- Modified Case - After Compute;

Synchronizing - Status is Modified and the Action is None. - Deleted Case - After Compute;

Synchronizing - Removes the instance of the fastener.

Automatically Assign and Reassign Fasteners

When this preference is ON and pilot and joined parts are planned by Generate MBOM or Synchronization Manager or Drag and Drop, fasteners for linked parts are generated.

Planning a pilot and joined parts, 2 manufactured parts for them generate and also a fasten item also generates.