Using Synchronization to Revise a Resulting Product | ||||

|

| |||

Revision Management of Manufactured and Corresponding Items

Here is a revision scenario of four Split Plates for one Panel and one Stiffener case.

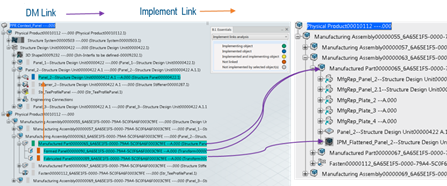

After new revision of input product (--- to --A) and replacement by new revision, the implement link between input product and Mfg. Item breaks. Select rows for Panel and Stiffener displays Revised status after computation.

There are two conditions to decide action for Revised status after computation.

- For the broken implement link between an input product assembly and Manufacturing Assembly, the Synchronization Manager displays Revised status and Reroute action.

- For broken implement link between leaf elements, Synchronization Manager displays Revised status and Reroute/Revise action depending on Same Revision/Up or Down Revision of Product.

After synchronization, the Synchronization Manager displays the Up-To-Date status and None action for corresponding rows.

In the specification tree, manufactured items revises and implement links reroute.

Resulting products revise and Product Instance under IPM is replaced by --A revision.

Manufactured Part with Resulting Product

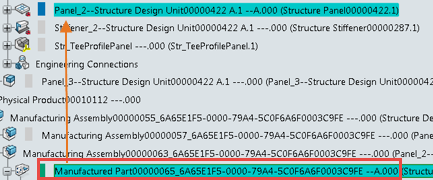

- Case a:New revision of Input Product.

Input products (Part 1.A, Part2.A) then revises the (Part 1.B, Part2.B) and replaces in the specification tree. Then, implement links between input products and the Mfg. Items brake.

After Synchronization Manager command execution, the result:

In this scenario, the revision and replacement of Manufactured Parts done before this function. This function focuses on revision and replacement of the Resulting Product.

- Resulting Product:

Prior confirmation is done to see if there is already a revision of the Resulting product available in the database, which matches with the B revision of the Product.

This lists, all revisions of the Resulting Products, and Product Instance under it retrieves. The revision of Input Product implemented by the Manufactured Part matches with the revision of Product Instance under the resulting product. In this case, only one revision found, A, then it considers to be the perfect match and no new revision of the Resulting Product completes.

If no matching revision appears, the new revision of the Resulting Product completes. In the present case, since no matching Product Instance is available, the new Revision of the Resulting Product completes.

The old occurrences of Resulting Products (IPM1.A, IPM2.B) under the context of Root Resulting Product are replaced with the new revision of Resulting Products (IPM1.B, IPM2.B).

- Product Instance:

The old Product Instances (Part1.A, Part2.A) under the revised Resulting Products (IPM1.B, IPM2.B) are replaced by the existing revision (Part1.B, Part2.B).

- Resulting Product:

- Case BBack Revision of Product from B to

A.

Here, Input Products (Part1.B, Part2.B) replace by the old / existing revision (Part1.A, Part2.A) in the specification tree.

After the Synchronization Manager command, the result:

-

In Case1, there is an existing revision of the resulting Product (Part1.A, Part2.A) available in the database. This aggregates Product Instance of revision A, no new revision of Resulting Product completes.

The Resulting Products under the Root Resulting Product context are replaced with A revision. No replacement for Product Instance is required since Product Instance of appropriate revision (A) is already existing under the Resulting Product.

In both cases, after the Revise and Replace actions, data materialization link establish between the revised Manufactured Part and the revised Resulting Product.

Manufactured Part with Predecessor Mfg Items

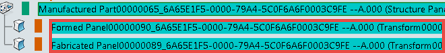

In this image:

- Manufactured Part00000065 and Formed Panel00000090 is pointing to the same Resulting Product.

- Fabricated Panel00000089 is pointing to the Flatten IPM (IPM_Flattened_Panel_2) which is aggregated under the IPM.

The input product revises and replaces by the new revision.

On execution of the Synchronization Manager command,  the following objectives are achieved:

the following objectives are achieved:

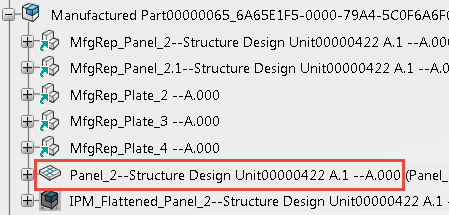

- Manufactured Part - New revision of Manufactured Part00000065

(--0 to --A) is done and the implement link is

rerouted between revised Manufactured Part00000065

(--A) and input product

(--A). Old Manufactured

Part00000065

--0 is replaced with --A

revision.

- Resulting Product of Manufactured Part - It is Revised from

--0 to --A and Data materialization link (DM

Link) is established between revised

Manufactured Part00000065 and revised

resulting product.

- Predecessor Mfg. Items - Predecessors revise and replace.

- Resulting Product of Predecessors - Resulting product of Formed Panel00000090 is pointing to the same resulting product of Manufactured Part00000065. So, Data Materialization Link (DM Link) is established between revised Formed Panel00000090 and revised IPM. Replace action does not complete since it is a same Resulting product. Resulting product of Fabricated Panel is revised from --0 to --A and Data materialization link (DM Link) is established between revised Fabricated Panel 00000089 and its revised resulting product.

- Product Instance under Resulting product - Product Instance is

replaced with existing revision

--A.

- Representations under the resulting product: This behavior governs the Infrastructure revision

mechanism.

- Make reusable Representation: These representations do NOT automatically revise when the resulting product revises. The Synchronization Manager command does not explicitly execute revision of these types of Representations.

- Non-Make reusable representation - These representations automatically revise if the resulting product under which it is aggregated revises. The Synchronization Manager command does not explicitly execute revision of these types of Representations.

Documents

- XML - XML linked to the Manufactured Part verify by Manufacturing Finder.

After revision of the Manufactured Part in the Synchronization process, this document revises and relinks to the revised Mfg. Item.

- Drawing representations aggregated under the Resulting Product.

If this drawing representation is aggregated as make reusable Representation, then the representation does not automatically revise.

If the drawing representation is non make reusable, then automatic revision when the Resulting product is revises.