Resource Programming Without Planning Data

A manufacturing product can be created as any other resource.

Inserting a Manufacturing Product resource (via Existing Product or Resource) creates an empty manufacturing product at the specified organizational resource level (station, line, etc.). It can only be inserted on an organizational resource.

The grab activity allows for selection of product under a manufacturing product. With this programming model:

- Attachments can be created between a manufacturing product and a device, as both are resources.

- There are no PPR context dependencies.

- A product that is under a PPR context cannot be selected, except those that are implemented by process planning data.

Line Simulation with No Process Planning Data

Dynamic rerouting occurs when manufacturing products are manually built from each station/line under the following conditions:

- Each intermediate assembly is defined by a physical product and inserted in the manufacturing product of the appropriate stations

- Depending on the assembly flow, these intermediate assemblies are inserted into each other

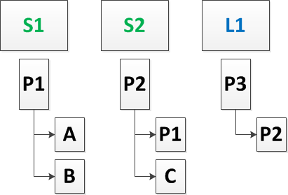

Example 1: One Line, Two Stations, Sequential Assembly Flow

- Station 1 (S1) > assemble A and B

- Station 2 (S2) > assemble C on AB

There are two assembly steps in this scenario:

- Product 1 containing A and B

- Product 2 containing C and Product 1

The manufacturing product contains:

- For Station 1 (S1): Product 1

- For Station 2 (S2): Product 2

- For Line (L1): Product 2, or a product that contains Product 2

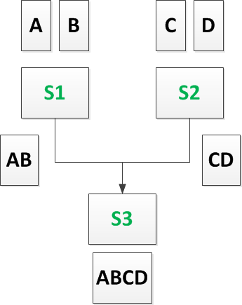

Example 2: One Line, Three Stations, Parallel Assembly Flow

- Station 1 (S1): assemble A and B

- Station 2 (S2): assemble C and D

- Station 3 (S3): Assemble AB and CD

There are three assembly steps in this scenario:

- Product 1 containing A and B

- Product 2 containing C and D

- Product 3 containing Product 1 and Product 2

The manufacturing product contains:

- For Station 1 (S1): Product 1

- For Station 2 (S2): Product 2

- For Station 3 (S3): Product 3

- For Line (L1): Product 3, or a product that contains Product 3

When the active simulation object is changed, the manufacturing product structure of the active resource is checked for validation. A message is displayed if dynamic rerouting on the active resource cannot work with respect to its children.

If the structure is valid, the simulation of a line can safely reuse links on the manufacturing product content of stations in the manufacturing product of the line.