Creating a Multi-Axis Flank Contouring with Non-Adjacent Drives on Different Solids | ||||

|

| |||

- From the Surface Machining section of the action bar, click Multi-Axis Flank Contouring

.

.

A Multi-Axis Flank Contouring entity is added to the manufacturing program.

The Multi-Axis Flank Contouring dialog box opens directly at the Geometry tab

.

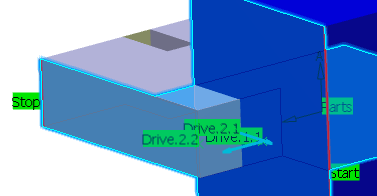

.The parts, drives and start/stop areas of the sensitive icon are colored red indicating that this geometry is required. All other geometry is optional.

-

Still in the Geometry tab:

- Select the part surface (underside of gray solid, for example).

- Select the start and stop limiting elements.

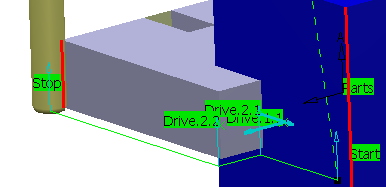

- Select a first drive on the flank of the blue solid and the second on the flanks of the gray solid.

Those drives are not adjacent: They belong to different solids. Stopping and Restarting conditions must be defined on non-adjacent drives.

Arrows appear on the drives indicating the orientation for each adjacent section. - Make sure those arrows are oriented outward.Note: Arrows appear whenever necessary to indicate the orientation for the drive selection. Make sure that they are correctly oriented.

- Still in the Geometry tab, right-click the drive surfaces area

in the sensitive icon

and select

Local Modifications. The Local Drive Surfaces dialog box appears.

- Modify the first drive:

- Double-click line 1.The Local Drive Surface 1 dialog box appears.

- Set the Stopping condition to To.

- Click >> to access the Local Drive Surface 2 dialog box.

- Set Restarting direction to Left.

The Local Drive Surfaces dialog box is updated.

Note: Right-click in the Local Drive Surfaces dialog box to access a number of context commands:- Column Order and Column Filter for managing the columns of information that are shown.

- Properties for accessing the dialog box of the selected local drive.

- Reset to reset local drive selection in the list.

- Copy, Cut and Paste for managing the list of local drives.

- Double-click line 1.

- Go to the Tools tab

to select a tool.

to select a tool. -

Click Display or

Simulate to check the validity of the machining operation.

- Click OK to create the machining operation.