Creating a Cavities Roughing Operation | ||||

|

| |||

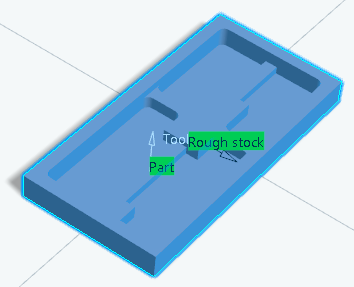

- Create a rough stock on the part to machine.

- From the Surface Machining section of the action bar, click Cavities Roughing

.

The Cavities Roughing dialog box appears directly at the Geometry tab

.

The Cavities Roughing dialog box appears directly at the Geometry tab .

.

- Select the Rough stock

and the Part to machine.

- Go to the Machining Strategy

tab

and set the Center Definition parameters as listed below.

and set the Center Definition parameters as listed below.- Remaining thickness for sides to 3mm

- Minimum thickness on horizontal areas to 0mm

- Do not select Machine horizontal areas until minimum thickness

- Select Pocket filter

- Go to the Tools tab

to select a tool.

to select a tool. -

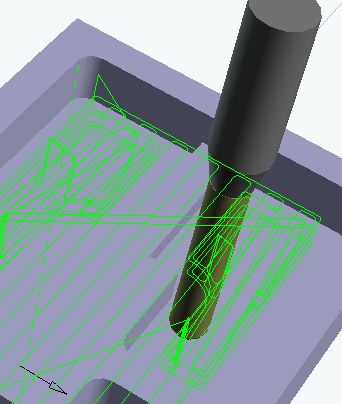

Click Display or

Simulate to check the validity of the machining operation.

- The tool path is computed.

- A progress indicator is displayed.

- You can cancel the tool path computation at any moment before 100% completion.

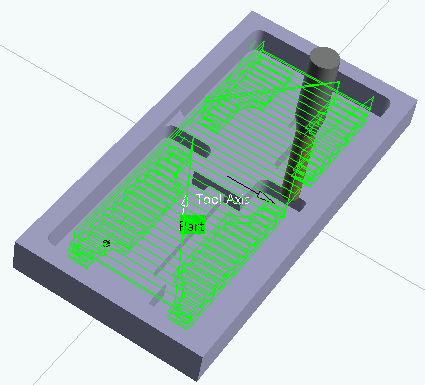

- In the Machining Strategy tab

,

right-click the machining direction arrow and select Optimize.

,

right-click the machining direction arrow and select Optimize. -

Click Display or

Simulate again.

The tool path direction has been adapted to the geometry to machine: It is defined by the shape of each pocket and set along the main direction (X or Y).

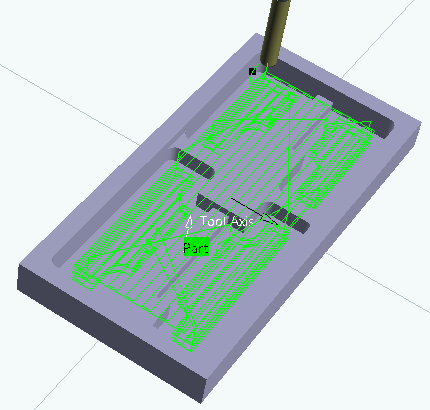

- Go to the HSM tab and make sure the High speed milling check box is selected.

-

Click Display or

Simulate again.

Note: The corners are now rounded for high speed milling.