Creating a Multi-Axis Tube Machining Operation Around Guide | ||||

|

| |||

- From the Surface Machining section of the action bar, click Multi-Axis Tube Machining

.

A Multi-Axis Tube Machining entity is added to the manufacturing program. The dialog box opens at the Geometry tab

.

A Multi-Axis Tube Machining entity is added to the manufacturing program. The dialog box opens at the Geometry tab .

.

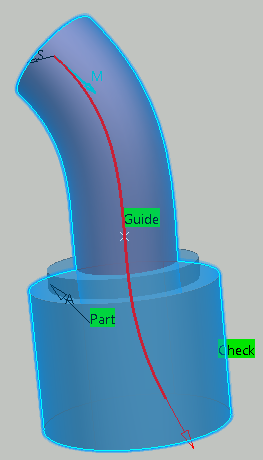

- Still in the Geometry tab:

- Click the red area representing the part to machine.

The dialog box disappears.

- Select the part. Double-click anywhere in the work area to validate the selection

and revert to the dialog box.

The red area has turned green. - Right-click the area representing the check.

The dialog box disappears.

- Select the check.

Double-click anywhere in the work area to validate the selection

and revert to the dialog box.

The check area has turned green.

- Click the red area representing the part to machine.

- Go to the Machining Strategy

tab.

tab.

- Make sure the Guiding strategy is set to Around guide.

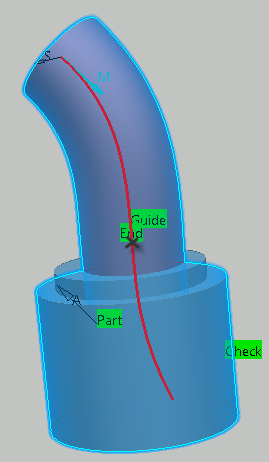

- Click the line in the sensitive icon and select the curve.

- Set the Side to machine to Inside.

- Click the end point in the sensitive icon and select an end point.

- Go to the Tool Axis tab.

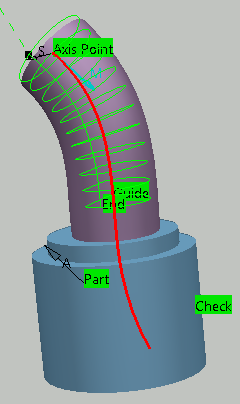

- Set Tool axis mode to Thru a point.

- Click the To point that has appeared in the

sensitive icon and select the top end of the curve.

- Go to the Tools tab

and select a T-Slotter tool.

and select a T-Slotter tool. -

Click Display or

Simulate to check the validity of the machining operation.

- The tool path is computed.

- A progress indicator is displayed.

- You can cancel the tool path computation at any moment before 100% completion.

- Click OK in the Display or

Simulate dialog box, and again in the main dialog box to create the machining operation.The tool path is created.