- From the Surface Machining section of the action bar, click Multi-Axis Tube Machining

. .

A Multi-Axis Tube Machining entity is added to

the manufacturing program.

The dialog box opens at the Geometry tab

. - Still in the Geometry tab:

- Click the red area representing the part to machine.

The dialog box disappears.

- Select the part.

Double-click anywhere in the work area to validate the selection

and revert to the dialog box.

The red area has turned green.

-

Go to the Machining Strategy tab

. .

- Set the Guiding strategy to Helical.

- In the Machining tab,

set Driving tool points to Tool tip,

Side to machine to Inside and

Zone to Cavity.

-

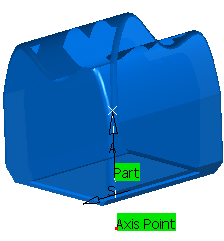

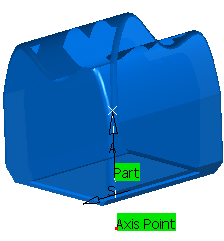

Go to the Tool Axis tab:

- Set Tool axis mode to Thru a point.

- Change From to To.

- Select a point as the Axis Point.

- The part is shown in blue.

- The axis point in shown as the red dot.

-

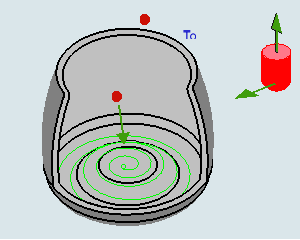

In the sensitive icon:

-

Right-click the axis

and

select As guiding axis in the context menu.

The icon turns to.

-

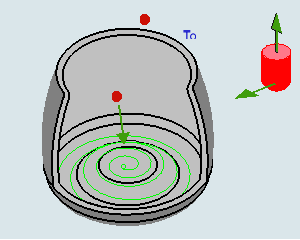

Click the red dot and select a point as the center of the cavity to machine.

- Click the arrow representing the tool axis and set the tool axis to (0,0,-1).

The tool axis A (black arrow) specifies where the cavity is located. The Machining direction M (orange arrow) specifies that the machining is performed from bottom to top.

- Go to the Tools tab

: :- Select a Lollipop tool.

- Define its diameter.

-

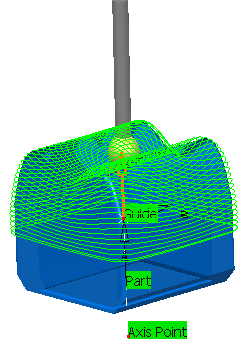

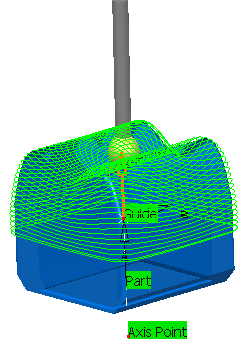

Click Display or

Simulate to check the validity of the machining operation.

- The tool path is computed.

- A progress indicator is displayed.

- You can cancel the tool path computation at any moment before 100% completion.

- Click OK in the Display or

Simulate dialog box, and again in the main dialog box to create the machining operation.

Multi-Axis Tube Machining.1 is created in the process

table.

-

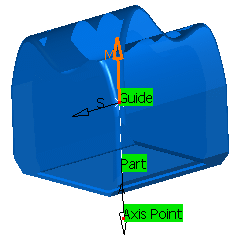

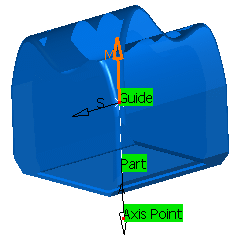

Copy Multi-Axis Tube Machining.1 and edit it:

- Change its name to Multi-Axis Tube Machining.2.

- Set Side to machine to Outside.

- Change To to From.

- Select a line as the guiding curve and

reverse the tool axis.

Note:

The center of the cavity is one of the end points of the guiding

curve.

If you define a relimiting point, this point will become the center

of the cavity.

-

Click Display or

Simulate to check the validity of the machining operation.

- The tool path is computed.

- A progress indicator is displayed.

- You can cancel the tool path computation at any moment before 100% completion.

- Click OK in the Display or

Simulate dialog box, and again in the main dialog box to create the machining operation.

Multi-Axis Tube Machining.2 is created in the process

table.

|

.

A Multi-Axis Tube Machining entity is added to the manufacturing program. The dialog box opens at the Geometry tab

.

A Multi-Axis Tube Machining entity is added to the manufacturing program. The dialog box opens at the Geometry tab .

. .

.

:

: