- From the Surface Machining section of the action bar, click Multi-Axis Tube Machining

. .

A Multi-Axis Tube Machining entity is added to

the manufacturing program.

The dialog box opens at the Geometry tab

. -

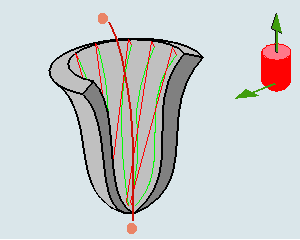

Go to the Machining Strategy tab and select a Guiding strategy mode:

- Around guide,

that lets you choose between two tool path styles: Zig zag or One way. - Along guide,

that lets you choose between three tool path styles: Zig zag, One way or Back and forth. - Helical.

-

Select a guide:

- Click the curve in the sensitive icon and

select one in the work area, or right-click the curve in the sensitive icon and

select As guiding axis,

Another sensitive icon is displayed.  - Click the red point and the arrow to select one point and an axis

direction.

When this icon is displayed: - The context menu changes to bring

you back to the other selection mode.

- The machining direction (M arrow) is displayed at one end of the

guide.

- Click this arrow to invert the machining direction if necessary.

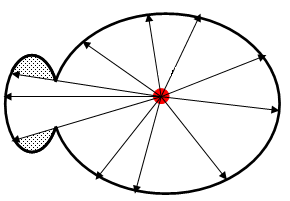

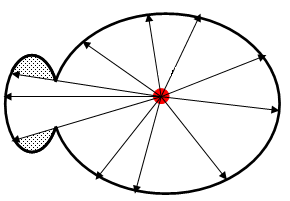

- Areas that cannot be reached by the beams issued from the guide

are not machined.

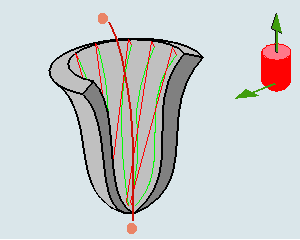

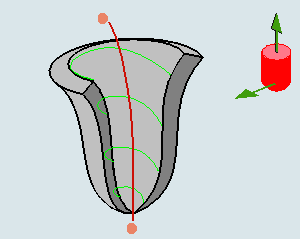

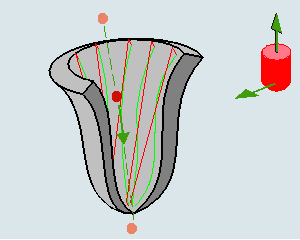

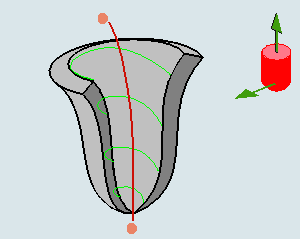

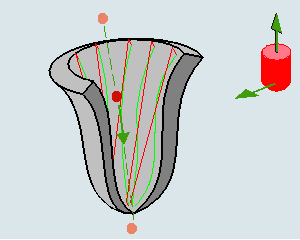

In the pictures below,

- The guide is represented in red.

represents areas that are not

machined. represents areas that are not

machined.

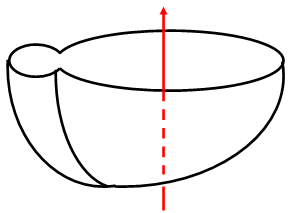

View normal to the guide

-

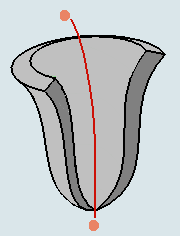

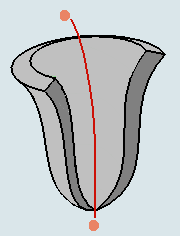

Select the limiting points (represented by the dots below).

- Click the limiting point in the sensitive icon and select a

point in the work area or right-click the limiting point in the sensitive icon and

select On guide in the context menu.

A red dot appears on the guide. - Drag the red dot to the

required position.

-

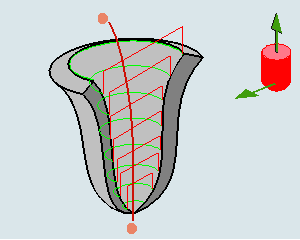

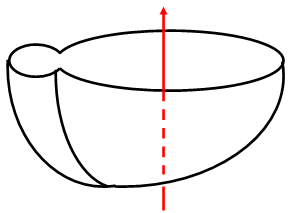

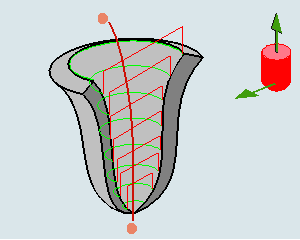

Define the tool axis:

-

Click the vertical arrow to define the tool axis.

-

Click the horizontal arrow to define the start direction.

The start direction can be:

- The beginning of each pass if the Guiding strategy

is set to Around guide.

- The location of the first pass if the Guiding

strategy is set to Along guide.

- or the beginning of the helix if the Guiding

strategy is set to Helical.

- Set the other parameters of the machining operation as required.

|

.

A Multi-Axis Tube Machining entity is added to the manufacturing program. The dialog box opens at the Geometry tab

.

A Multi-Axis Tube Machining entity is added to the manufacturing program. The dialog box opens at the Geometry tab .

.

represents areas that are not

machined.

represents areas that are not

machined.