Optimizing a Power Machining Operation | ||||

|

| |||

- From the Surface Machining section of the action bar, click Power Machining

.

A Power Machining entity is added to the manufacturing program. The dialog box opens at the Geometry tab

.

A Power Machining entity is added to the manufacturing program. The dialog box opens at the Geometry tab .

. - Still in the Geometry tab, click the corresponding spots in the sensitive icon and:

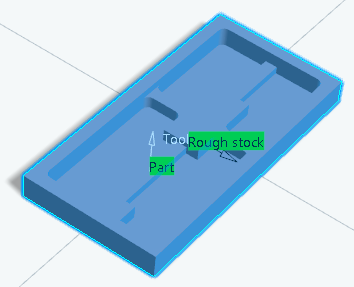

- Select the Rough stock

and the Part to machine.

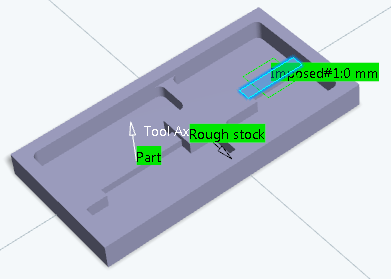

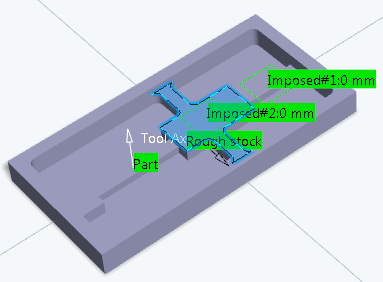

- Define two imposed planes:

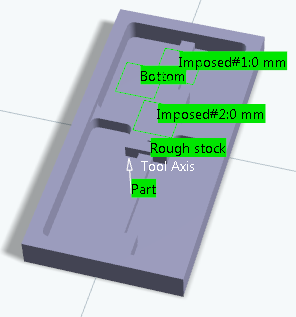

- Define the bottom:

- Define the Zone order:

- Select the Rough stock

- Set the following parameters.

- Machining strategy: Center(1) and Side(2)

- Offset on Part: 0.5 mm

- Machining mode: Pocket only

- Machining tolerance: 0.1 mm

- Remaining thickness for sides:1 mm

- Bottom finish thickness: 0.5 mm.

Note: The specificity of the Power Machining is the tool loading management in Back and Forth:- Several contouring passes

- No full diameter cuts with zig zag passes

- Possibility to perform the contouring passes prior or after the zig-zag passes

- Possibility to define a contouring pass ratio.

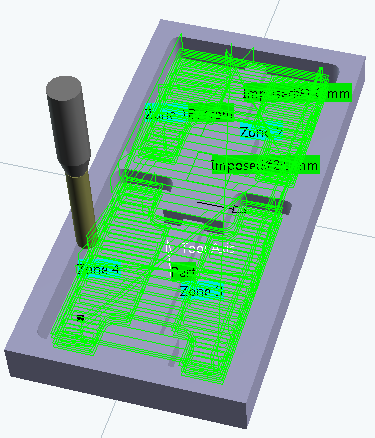

Tool path with the values defined above:

- Right-click the machining direction arrow and select Optimize from its context menu.

- Go to the Tools tab

to select a tool.

to select a tool. -

Click Display or

Simulate to check the validity of the machining operation.

The tool path direction has been adapted to the geometry to machine, i.e. defined by the shape of each pocket and set along the main direction (X or Y). - Modify the Contouring pass ratio.

This parameter is available when the Tool path style is set to Back and Forth. It adjusts the position of the final pass for removing scallops. This is done by entering a percentage of the tool diameter (0 to 50).

Contouring pass ratio is set to 0:

Contouring pass ratio is set to 50:

- Go to the HSM tab and make sure the High speed

milling check box is selected.

Without the High speed milling option:

With High speed milling option:

The tool path is rounded to give a smoother path that can be machined faster.