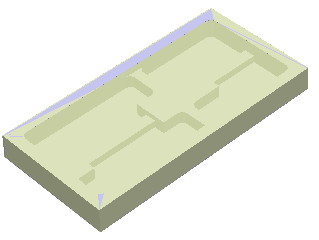

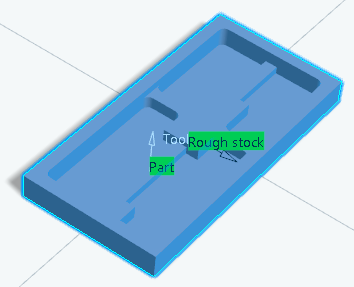

- You are going to machine the center of a part like this one.

If it does not yet exist, create the

rough stock.

- From the Surface Machining section of the action bar, click Power Machining

. .

A Power Machining entity is added to the

manufacturing program.

The dialog box opens at the Geometry tab

. - Still in the Geometry tab:

- Click Part in the sensitive icon and select the

part.

- Double-click anywhere in the work area to revert to the dialog box.

- Click Rough stock in the sensitive icon and select the rough

stock.

- Go to the Strategy tab

and make sure the

Machining strategy is set to Center(1) only. and make sure the

Machining strategy is set to Center(1) only. - Go to the Tools tab

to select a tool. to select a tool. -

Click Display or

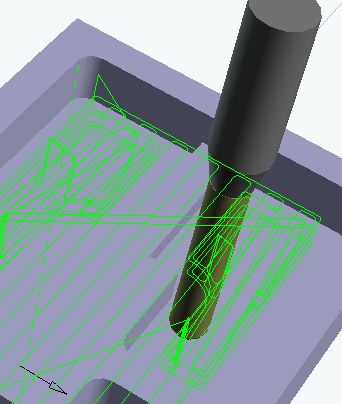

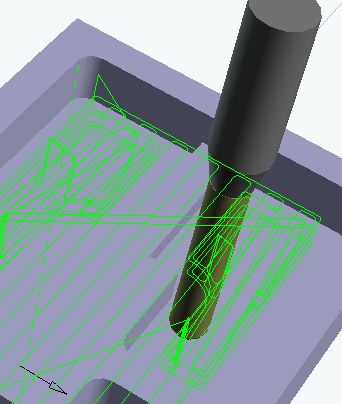

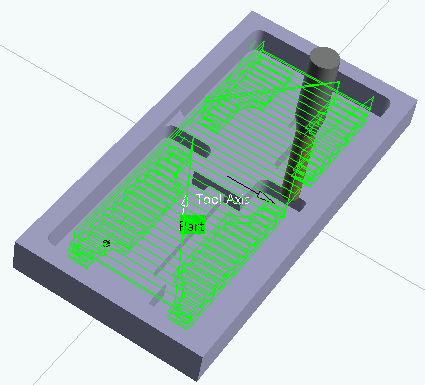

Simulate to check the validity of the machining operation.

- Go to the Geometry tab

to optimize the tool path. to optimize the tool path.- Right-click the machining

direction arrow and select Optimize from its context menu.

-

Click Display or

Simulate to check the validity of the machining operation.

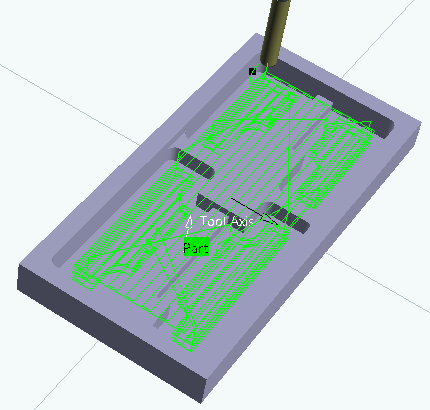

The tool path direction has been adapted to the

geometry to machine,

i.e. defined by the shape of each pocket and set along the main

direction (X or Y). - In the Strategy tab

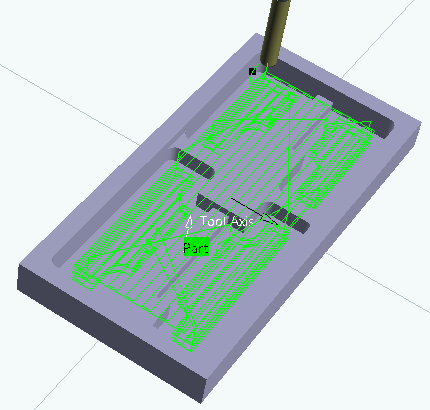

, go to the Center tab, then the HSM tab and make sure the High speed milling

check box is selected. , go to the Center tab, then the HSM tab and make sure the High speed milling

check box is selected. -

Click Display or

Simulate to check the validity of the machining operation.

The corners are rounded.

|

.A Power Machining entity is added to the manufacturing program. The dialog box opens at the Geometry tab

.A Power Machining entity is added to the manufacturing program. The dialog box opens at the Geometry tab .

.

and make sure the

Machining strategy is set to Center(1) only.

and make sure the

Machining strategy is set to Center(1) only. to select a tool.

to select a tool.

to optimize the tool path.

to optimize the tool path.

, go to the Center tab, then the HSM tab and make sure the High speed milling

check box is selected.

, go to the Center tab, then the HSM tab and make sure the High speed milling

check box is selected.