Accept Orders | ||

| ||

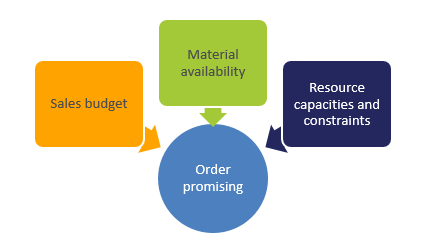

The task for Order Acceptance is to determine a date quoted to the customer using a combination of the available sales budget, material, capacity, and minimal lead times. The resulting date is the Proposed Confirmation Date, which is the maximum of the:

- Sales Budget Reservation Date.

- Planned Date.

This ensures that resources budgeted for customers who have not placed their orders yet are not allocated to another customer. It also ensures that all current booked orders do not exceed the available materials and resources.

Orders are entered in the Enterprise Resource Planning (ERP) system. To promise an order, place the demand and supply orders in an intermediate database:

- Master Production Scheduling polls this database at timed intervals and updates by planning order by order.

- Order confirmations are “published” to the external system either by user initiation or as an automated step during the planning run.

- The user in ERP can decide to repromise if the Planned Delivery deviates too much from the original Confirmed Delivery. This is a user decision.

- There is no global optimization for this planning decision. Instead, the new order will be planned using the free capacity, without replanning other orders. This approach enables the system to give a reliable answer quickly.

- Order acceptance happens during the day with a maximum response time of 15 minutes.

- The interface between the ERP and Master Production Scheduling is based on the standard integration database. A time trigger for online order acceptance is added with the configured frequency to pull orders to Master Production Scheduling. Technically this approach is still asynchronous communication (no messaging or waiting transactions).