Plan Work Orders | ||

| ||

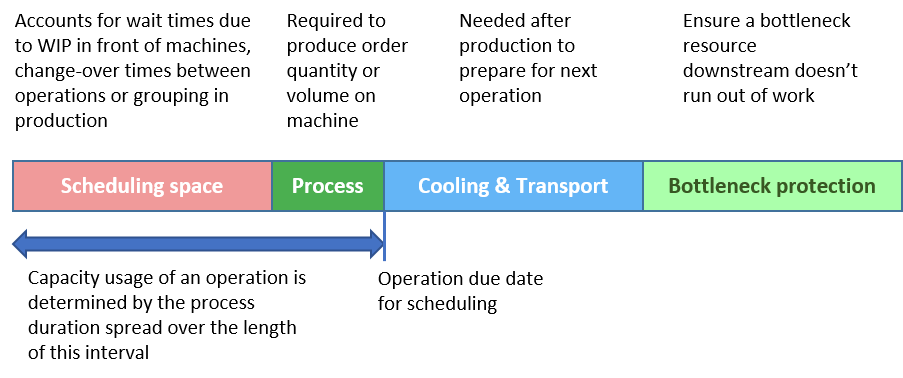

During any production process, there are waiting times between operations, for example transport times. Other wait times may depend on the detailed scheduling decisions, for example setups. To support planning on a continuous timeline in the context of bucketed capacity, Master Production Scheduling implements lead time logic at the supply order operation level.

The lead time of an operation supports the use of one or more of the following components:

The usage of these components varies depending on the implementation.

Master Production Scheduling cannot consider setup times since it does not create a sequenced schedule. To arrive at realistic lead times, scheduling space is used. Scheduling space is required to give room to optimally sequence and batch in detailed scheduling, but this needs to be reduced to the minimum requirement to avoid unnecessarily long throughput times.

Master Production Scheduling supports a standard cycle for planning delivery dates by the optimizer and publishing this data back to an ERP or MES system. Manual creation and publishing of proposed supplies is also supported.

Work order planning details for work order supplies are visible on a Gantt chart on the Customer Orders view. Lead times and their constituent components are visualized on assigned resource groups. Planners can manually push work orders earlier or later, or extend scheduling space.

Work order planning may also be visualized on a Gantt chart in the context of resource utilization in the Capacity Overview.