Reserve Material | ||

| ||

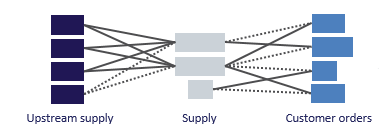

Master Production Scheduling executes Material Reservation based on supply and demand quantities, not individual orders, allowing for many-to-many relationships between supplies and demands. It also executes Material Reservation based on the unique Product ID, which means that the detailed length of an ingot, for example, may be ignored and only the Product ID is used to identify the material.

Material reservation is performed by quantity in a single system-wide unit of measurement. However, support for reservation in multiples of piece weight is supported to ensure that indivisible supplies, such as coils, inventory packages, and work order batches, are reserved as complete units to more accurately reflect real world consumption constraints. Master data defines piece weight, but tolerances in live production are allowed. These tolerances are defined in the system configuration interface.

Product-based reservations are presented in a Supply and Demand form where a planner may view and update all demand and supply fulfillments in a list-based format. You may also view material reservations from the Material Planning Overview where net inventory positions are represented in configurable time buckets. One or many time bucket nodes may be selected to show the associated material reservation detail for the selected period.