During the launch of NC Code simulation, if the controller emulator detects unknown or unsupported NC Code, it generates warnings or errors based on the severity. These errors are shown in the existing Message Reporting dialog box.

- Click Messages Reporting

.

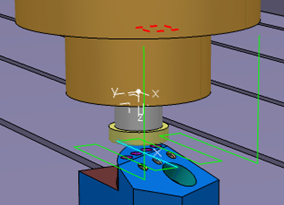

.The dialog box showing the Message

NC Code syntax error:Line5, Tr45 Apart from the feedback and machine

positioning capability, you are

warned of Unsupported ISO Code. Unsupported ISO code is any

parameter or instruction in the NC Code which is not understood by

the controller. These errors are generated by the controller

emulator and is shown in an error / warning dialog box before

the simulation player is launched. Based on the error warning status,

you can continue the simulation or close the simulation

tool bar.

If machining (feed) moves are detected when

the spindle is not on (CW or CCW) then this is flagged as an

error during simulation. This is a fault type in the

list.

During simulation, if machining is detected when spindle is not on, then this is flagged as error. In Live Simulation, this shows in the simulation status area (bottom center of screen). This is also included in the Hide/Show Information Messages, available at end of simulation.

- Click Show/Hide Information Messages

This shows information messages: 4s: Joint limit exceeded by ZIMMERMANN_F302Zimmerman27990-422916793.1::Axis X 2.9s : Joint limit exceeded.