This is particularly

related to Milling machines in which a master or universal milling

head can be coupled selectively and automatically with a variety of

individual milling heads for different machining purposes. The

individual milling heads are a part of the machine

itself.

A head change position and head

mount point has to be defined in Manufacturing Equipment Design

App on the master or universal milling head. Also a head base point

has to be defined on the individual milling heads. During

simulation, the interchangeable head is equipped to the head

mount point of the master or universal milling machine at this head

change position (the orientation of the attached milling head depends on the head base point of the attached milling head and the

head mount point of the master milling head). Also note that when

an interchangeable head is equipped to the master milling head, the

tool is mounted at the tool mount point of the attached

milling head.

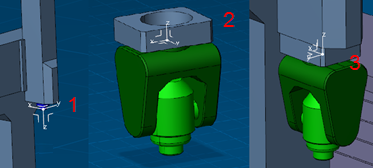

The orientation of the head mount point (1) and the head base point (2). The orientation of the head mount point and the head base point are used to snap the milling head on the machine (3).

This machine can only simulate machining

operations for which the tool axis is along the Z-Direction. So to

simulate machining operations which have different tool axis

interchangeable milling heads can be used as shown above.

Also the conception of the machine

fitted with interchangeable milling heads allows you to select

an optimal milling head for a particular machining

operation.