Simulating the Tool Path | |||

| |||

Simulate a Section of the Tool Path

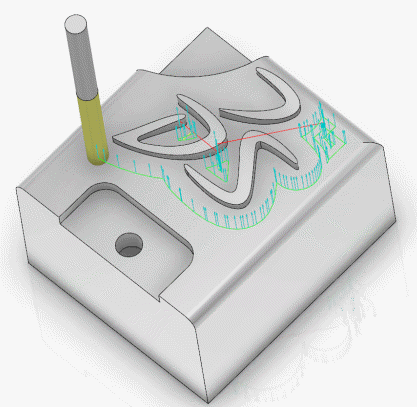

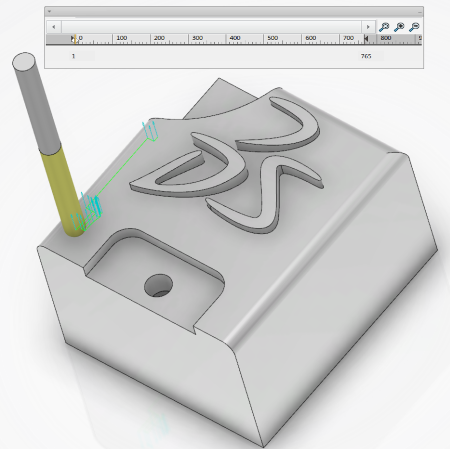

Once the complete tool path is simulated, you can simulate a section of the tool path using the tool path line.

-

On the tool path line, define a start point by moving the

arrow to the

required point.

arrow to the

required point.

-

Define an end point by moving the

arrow to the

required point.

arrow to the

required point.

- From the experience player, click Play Forward

.

.

The tool path section you defined is simulated.

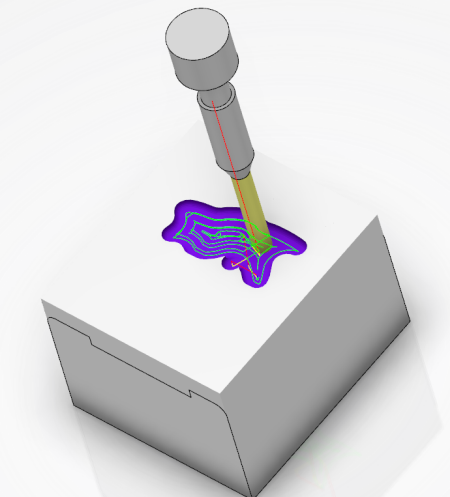

Simulate Material Removal

You can simulate material removal when simulating a tool path.

Before you begin: In the Activities Process Tree:

- Click Select to Enable Material Removal During Simulation

. Alternatively, select the Enable Material Removal check box in the NC Simulation tab of the Simulation Options dialog box.

. Alternatively, select the Enable Material Removal check box in the NC Simulation tab of the Simulation Options dialog box. - For mill-turn machines, activate the machine kinematic by clicking Activate/Deactivate Machine Kinematic

.

.